Rami Alsodi1, Mufid Samarai2, , Hadif Alsuwaidi1

- Department of Civil and Environmental Engineering, College of Engineering, University of Sharjah, P. O. Box 27272 Sharjah, Sharjah, UAE. U21200094@sharjah.ac.ae; U19105743@sharjah.ac.ae

- Sahara Consultations, P. O. Box 2580, Dubai, UAE. mufid@saharagcc.com samarai@sharjah.ac.ae

Abstract #

Construction is considered one of the main consumers of resources and energy as well as the most damaging to the environment, generating one of the largest amounts of CO2. Cement, an important component of concrete, is one of the most widely used construction materials in the world, and it is solely responsible for about 7% of CO2 emissions. This highlights the importance of quality control, maintenance, and sustainability in preserving the current built stock and extending the life cycle of the standing structures, also ensuring that their impact on the environment during their utilization is kept minimal.

Maintenance is important where there are critical factors influencing the durability of buildings. Such factors include deleterious substances, sulfate and chlorides, and hot weather. For example, high temperatures greatly accelerate the effect of all these factors and, consequently, reduce the life span of the concrete if proper precaution is not taken. Building maintenance and durability have attracted the recognition of professionals and academics in this field for their ability to elongate the lifespan of the building and achieve sustainability. Recently, there has been more awareness of environmental issues and the importance of maintenance and quality control as a tool for sustainability.

This paper shed the light on the trends and advances in sustainability regarding concrete; it elaborates on the durability and deterioration of reinforced concrete structures. It emphasizes the importance of maintenance and repair of existing structures as part of the sustainability and extension of the life cycle performance and serviceability. Finally, it conducts a life cycle analysis to compare the periodic maintenance and reconstruction of buildings.

Keywords

Sustainability, Maintenance, Durability, Life Cycle Analysis, Advanced NDT

1 Introduction #

The construction industry is one of the largest materials consumers in terms of energy and resources. Many processes are associated with this depletion, such as the energy consumption and waste generation of the production of the cementations binder and associated reinforcing steel, the mining and transport of aggregates, as well as the transportation of the mixed concrete to the job site. Most of the negative environmental impacts of construction materials, especially concrete, occur during the manufacturing of the material. The production of concrete materials, such as Portland cement, is energy intensive and causes environmental pollution [1]. It is responsible for consuming approximately 7% of the total global emission of CO2. Thus, concrete production has a great impact on both the local and global environment.

In the 1960s, the compressive strength of concrete was considered the most important parameter. However, twenty years later, durability became more important. Nowadays, serviceability and sustainability are the most interesting topics for researchers and materials scientists. Fig. 1 shows the change in interest through the years of concrete development.

Fig. 1 Since 1960 the concrete development requirements shifted from compressive strength to maintainability and sustainability.

Concrete is generally believed to be a highly durable construction material once cured, but it is still prone to deterioration during its life cycle. Concrete is prone to several attacks, threatening its long-term durability. Physical attack, chemical attack, sulfate attack, leaching, and alkali aggregate reactions are the major factors that affect the stability and durability of concrete [2].

Deterioration of concrete structures certainly results in higher environmental harm and economic loss and more waste if the structure is beyond repair. This could lead to new construction if the function of the structure is still required.

Under such circumstances, the requirement for appropriate monitoring, maintenance, and repair strategies is particularly important to ensure that structures remain both functional and economically viable all through their design life and beyond. It is a fact that a comprehensive routine maintenance program can increase the life span of the concrete structure and thus, potentially contribute towards sustainability in the long run. A major repair is expected to cost much more than routine maintenance, and an all-out replacement can cause much more folds than a major repair. Regular maintenance and repair of concrete structures ensure that the environmental impact during their life cycles is minimal from the viewpoint of durability [3,4].

2 Construction Lifecycle and Sustainability #

Deterioration of reinforced concrete structures has emerged as one of the most difficult challenges in the construction industry, regulatory agencies, and society. Therefore, an appropriate design for durability, regular maintenance, and repair is vital for long-term performance of concrete like environmental protection, infrastructure protection, and maintenance require the efforts and resources of the present generation.

Construction practices were always based on Cost, Time and Quality, but recently, three more factors are considered, which are, Human satisfaction, Environmental impacts as well as Materials and Energy consumption. The reason for these changes is the increasing attention given to the sustainable design. Figure 2 shows the new introduced aspects of construction.

Fig. 2 Environmental impact, Energy and Material Consumption and Human Satisfaction are new aspects considered in the construction

in the construction

Sustainability is a very important pillar in the construction industry, especially in the present conditions of a rising greenhouse gas emissions, it incorporates three important dimensions which are ecological, economic, and social. It aims to meet the present-day needs for housing, working environments, and infrastructure, without compromising the ability of future generations to meet their own needs as well [5].

Fig. 3 Interactions between Three sustainability pillars

Ensuring sustainability entails an equal implementation of its pillars which are ecological, economic and social as shown in figure (3). The importance of the interaction between economic, social and ecological sustainability are described below:

- Ecological and Economical: The growing economical projects and investments depend on the resources from the environment. Thus, they affect the environment in different ways by depleting resources and pollution.

- Social and Ecological: The ecological system provides access to natural resources (food, water, air, soil, energy and so on.), well-being and working conditions and contributions to health. So if the consumption continues to grow unsustainably, it might result in negative environmental impacts, such as bad effects on health, thus, lowering the quality of life.

- Social and Economical: The economy will provide jobs while the human factor will provide productivity based on the quantity and quality of employers.

Ecological sustainability goals are resource protection, ecosystem protection and human health protection. The Effective protection of the ecosystem can be achieved by minimizing and eliminating wastes and preventing emissions to air, water, and soil. Protection of sensitive ecosystems is achieved by maintaining good construction practices and supervision. Natural Resources such as land, material resources and fossil fuel are depleted. They can be protected by reducing energy consumption in sites, designing for whole-life costs, use of local supplies and materials with low embodied energy, use of recycled materials, as well as water and waste minimization and management [6].

Economic sustainability is the ability of an economy to indefinitely support a defined level of economic production. Its objective is to maintain high and stable levels of local economic growth and employment. In construction, the most important sector, is the Life-cycle costs, such as the costs before and after the use of the building, maintenance and repair costs and operational costs [7]. Social sustainability is concerned with social progress, which recognizes the needs of the whole community, such as employment, stability and health.

3 Maintenance as a Tool to Enhance Concrete Life-Cycle #

Sustainable Construction implicates many issues in buildings design ,and management such as materials performance, construction technology and processes, energy and resource efficiency in building, operation and maintenance, robust products and technologies, long-term monitoring, adherence to ethical standards, stakeholder participation, occupational health and safety as well as working conditions, innovative financing models, improvement of existing contextual conditions, interdependencies of landscape, infrastructure, urban fabric and architecture, flexibility in usage of building, function and change, and the dissemination of academic-related, technical and social contexts.

In civil engineering, sustainability is an emerging term regarding planning, designing, maintaining, and operating concrete structures. Sustainability all about the efficient energy use, through conservative measures, such as maintenance and repair of existing structures; using renewable resources during construction; minimizing waste; reducing, recycling, and reusing of construction materials and products optimizing the resource usage. Therefore, sustainability in concrete structure can be achieved in two ways

(a) using green and energy-efficient material and green technologies when constructing the structure; and (b) preserving the already constructed structures by regular maintenance and repair. Sustainable advantages in terms of durability, cost, energy and cultural responsibility can be achieved by maintenance, repair and proactive protection [7].

Sustainable buildings provide direct economic benefits to all parties involved, by having a lower annual cost. The cost of energy, maintenance, repair, water, reconfiguring space and operation. The reduced annual costs do not change the fact that sustainable building needs a higher first cost than traditional buildings, but by using integrated design and low cost of sustainable materials and equipment, the first cost of the sustainable building will be the same or even lower than the cost for the traditional one. Some features will still have a higher first cost, but the life cycle cost is usually lower than that of traditional building. Moreover, sustainable buildings provide indirect economic benefits from having a longer building life cycle, lowering the risks, reducing the expenses of dealing with claims, attracting new employees, reducing costs from air pollution damage, and lowering infrastructure costs, by avoiding wastewater treatment plants for example [8,9].

Preventative Maintenance is performed to minimize or to avoid the need for repairs [10]. In some cases, the original design includes measures to protect the building, but in most cases, these measures are not included. Regardless of the lower life cycle impact that will occur on the long term, the reason for that is to reduce the initial construction cost. For example, in the arid and semi-arid regions, where severe weather conditions occur, many structures deteriorated due to material quality or design problems. Some buildings deteriorate as they were built to carry less loads than they actually do, or due to the accelerating construction works as they go faster to reach their completion time, ignoring some design standards. We can see that preventative maintenance is very important and should be done even if it’s not included in the design. Fig 4. Show how including multiple repair cycles can increase the age of the building after it is exposed to any form of chemical attack or damage [11].

Fig. 4 Regular maintenance can lead to sustainability by increasing the age of the building

4 Non-destructive Techniques for Maintenance and Assessment of Concrete Structures #

One important aspect of preventative maintenance to be considered is the periodic evaluation of the building. This can optimally be done by the use of non-destructive techniques. Maintainability of structures through non-destructive, modern monitoring techniques, especially for high-rise concrete structures, is very important. These modern monitoring technologies should be incorporated into the building design to facilitate its maintainability later on [12].

During the last years, there has been a continuous increase in the use of non-destructive testing (NDT) applied to many aspects related to the civil engineering field. This is mainly because most non-destructive methods work from a distance without direct contact with the structure. They provide a clear visualization of the object under study in terms of its structural capacity. The deterioration and condition of the reinforced concrete under the surface cannot be assessed by traditional visual and optical inspection. Alternative non-destructive methods have been developed for sub-surface inspections, including pulse propagation, magnetic, electrical, and electromagnetic as well as thermography and ground penetrating radar and infrared thermograph for the nearest sub-surface.

One of the most emerging techniques is using Unmanned Aerial Vehicle (UAV) and applications of photogrammetry. Photogrammetry is defined as “the art, science, and technology of obtaining reliable information from non-contact imaging and other sensor systems about the Earth and its-environment and other physical objects and processes through recording, measuring, analysing and representation”. It includes any type of sensors and cameras application used to obtain information. UAV is an aircraft which is is operated without an aircrew aboard and is instead controlled by a remote control or autonomously by on board computers [13]. Fig. 5 show an example of a UAV and NDT system.

Fig. 5 Example of a Drone (UAV) equipped with an NDT system [16]

Photogrammetry and UAV in civil engineering is almost unlimited. It could be used as a standalone system or jointly with other non-contact imaging data methods such as radar, LIDAR, holography and remote sensing. It could be used in architectural photogrammetry, information systems such as GIS and building information modelling (BIM) [14]. Deformation measurement and cracks opening during laboratory tests on structure and structural elements, crack measurement and monitoring, deflection beams, elongation in reinforced concrete real structure data acquisition and documentation such as bridges load testing, obtaining detailed geometries for computational structural models and visual documentation and modelling of actual symptoms (fissures, breaking, cracks or collapse) measurement of geometric and structural elements in bridge routine inspection Close range photogrammetry is employed for historic bridge documentation and routine inspection in bridge management.

5 Life Cycle Stages of Baseline Structures and Green Buildings #

Every product or building process, whether a normal baseline construction or a green building system, goes through various phases or stages in its life. It starts from material acquisition, then manufacturing and/or construction, use and maintenance, and end-of-life. Material Manufacturing includes the removal of raw materials from the earth, transportation of these materials to the manufacturing location, manufacture of finished or intermediate materials, engineering Materials production and fabrication, and packaging and distribution of building products. Construction accounts for activities relating to the actual construction of a building or structure. It includes transportation of materials and products to the project site, use of power tools and equipment during construction, on-site fabrication, and energy used for site work [15].

The use and Maintenance stage refer to building operation, which includes energy consumption, water use, and environmental waste generation. It also considers the maintenance and repair of building assemblies and systems. The efficiency and planning of the phase will not only elongate the life span of structures but also will keep them functional and useful for a longer period. At the end of the service life of structures, the building demolition and disposal of materials to landfills will add to energy consumption and to the environmental waste produced. The efficient use of recycled products and their reuse will be an asset and be considered as a positive impact and an asset to sustainability.

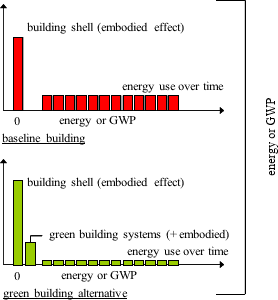

The described life cycle applies to both the normal baseline construction and the green building structures. However, the use of energy modeling is at the heart of the LEED rating system and, as such, is becoming more widely used as a building design tool. The reduction of both the embodied and operational energy consumed by the buildings is part of the Life Cycle Assessment and an essential tool to reduce Carbon Emissions and hence Global Warming [16].

Fig. 6 Comparison of the embodied effect baseline building and green building

The embodied and operational energies of the baseline building have the smallest embodied energy but use more energy over time. The green building alternative includes additional embodied energy from systems like high-performance insulation and glazing and photovoltaics however, over time, the energy embodied in the green build systems is “paid back,” and the overall impact of the green building, embodied and operational, becomes less than that of the baseline building as shown in Fig. 6.

6 Construction Life Cycle Assessment: Case Study #

It is believed that periodic maintenance of concrete will lead to many advantages in terms of achieving sustainability and reducing the harmful impact on the environment. Life cycle assessment (LCA) is a versatile tool for quantifying, evaluating, comparing and improving the environmental impact any product during their life cycle, and it has been widely adopted [17,18]. A detailed Life Cycle Assessment study to evaluate the emissions and energy consumption associated with Concrete production can prove this concept. This section will present a small-scale LCA study for a G+2 building of a volume of 50000 m3. The building is assumed to have an essential purpose to the government and can’t be replaced. Data were collected from multiple resources including actual cases and interviews. The inventory of the study is summarized in the following table:

Table 1 Life Cycle Inventory of both case scenarios

The functional unit (FU) is having the building lasts for 50 years. A comparison between 2 cases will be evaluated. The first case is to do zero-maintenance and intend a whole new construction after 25 years. The second case is to apply overall evaluation and maintenance every 10 years to support the same building to stay for 50 years.

The system boundaries include the raw material extraction and processing, energy consumption, transportation, vehicle and equipment use and mobilization as well as construction operations. Processes like equipment manufacture and waste management were excluded from this study. Boundaries of the study doesn’t include the initial construction; it will compare between the case of whole reconstruction and periodic maintenance impact.

The LCA aims to assess the potential environmental and health human impacts related to each building case. CML-IA methodology was used to evaluate the impact assessment in this study. The impact was evaluated in terms of Acidification, Eutrophication and Climate Change.

Fig 7 summarizes the environmental impact comparison between establishing a new construction and implementing periodic maintenance at 50 years. A clear advantage of reducing negative emissions is to the application of periodic maintenance.

OMAINTE

Fig 7 comparison of the environmental impact of applying periodic maintenance and reconstructing of the same building

7 Conclusions #

Maintenance is defined as the process of keeping a facility in such a condition that it may be utilized safely at its original capacity and efficiency for a longer life span. This is in a way is the key to sustainability in its simplest definition of being economical, beneficial to the society and preserving the environment. Academics and professionals became more aware of the importance of maintenance and is making big strides towards implementing sustainability and green buildings. It is believed that within less than two decades there will be no market for any products and utilities that will not adhere to the bylaws and guidelines that will enforce them.

We recommend that periodic maintenance of structures must be part of the design insuring that areas which are difficult to access can be monitored and maintained easily without the need of complicated procedures as maintenance have proven to have many advantages in terms of reducing the overall cost and the negative impact on the environment. Life Cycle Analysis studies can support this claim by analysing the impact and costs of the building over its overall life cycle.

References #

- Hendriks, C. A., Worrell, E., De Jager, D., Blok, K., & Riemer, P. (1998, August). Emission reduction of greenhouse gases from the cement industry. In Proceedings of the fourth international conference on greenhouse gas control technologies (pp. 939-944). IEA GHG R&D Programme Interlaken, Austria.

- Saetta, A., Scotta, R., & Vitaliani, R. (1998). Mechanical behavior of concrete under physical-chemical attacks. Journal of engineering mechanics, 124(10), 1100-1109.

- Vemund Årskog, Sverre Fossdal, Odd E. Gjørv. “Life –cycle Assessment of Repair and Maintenance Systems for Concrete Structures”. International Workshop on Sustainable Development and Concrete Technology, Norway, pp 193-200.

- Samarai, Mufid. “Sustainability of Reinforced Concrete Structures in the Gulf Region”, The 11th International Operation and Maintenance Conference in the Arabic Countries, 2013.

- Purvis, B., Mao, Y., & Robinson, D. (2019). Three pillars of sustainability: in search of conceptual origins. Sustainability science, 14(3), 681-695.

- Dewulf, J., Benini, L., Mancini, L., Sala, S., Blengini, G. A., Ardente, F., … & Pennington, D. (2015). Rethinking the area of protection “natural resources” in life cycle assessment. Environmental science & technology, 49(9), 5310-5317.

- Dwaikat, L. N., & Ali, K. N. (2018). Green buildings life cycle cost analysis and life cycle budget development: Practical applications. Journal of Building Engineering, 18, 303-311.

- Dutil, Y., Rousse, D., & Quesada, G. (2011). Sustainable buildings: An ever evolving target. Sustainability, 3(2), 443-464.

- Akadiri, Peter. Chinyio, Ezekiel. Olomolaiye, Paul. 2012. Design of a Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2(2), 126-152; doi:10.3390/ buildings2020126. (http://www.mdpi.com/2075-5309/2/2/126)

- MYDIN, A. O. (2015). Significance of Building Maintenance Management System Towards Sustainable Development: A Review. Journal of Engineering Studies & Research, 21(1).

- Samarai, M. (2016). In the Arabian Gulf maintenance is the key to sustainability. In Structures and Architecture (pp. 783-788). CRC Press.

- Riveiro, B., & Solla, M. (Eds.). (2016). Non-destructive techniques for the evaluation of structures and infrastructure (Vol. 11). Boca Raton, FL, USA:: CRC Press.

- M. A. Lazaridou and E. N. Patmio, “Photogrammetry; Remote Sensing and Geoinformation.” ISPRS – Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci., vol. XXXIX-B6, no. September, pp. 69–71, 2012, doi: 10.5194/ isprsarchives-xxxix-b6-69-2012.

- Zhang, D., Watson, R., Dobie, G., MacLeod, C., & Pierce, G. (2018, October). Autonomous ultrasonic inspection using unmanned aerial vehicle. In 2018 IEEE International Ultrasonics Symposium (IUS) (pp. 1-4). IEEE.

- Cole, R. J. (1998). Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Building and Environment, 34(3), 335-348.

- Wen, T. J., Siong, H. C., & Noor, Z. Z. (2015). Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy and Buildings, 93, 295-302.

- ISO ISO 14040, Environmental Management – Life Cycle Assessment – Principles and Framework, International Organization for Standardization, Geneva, Switzerland, 2006.

- ISO ISO 14044, Environmental Management – Life Cycle Assessment – Requirements and Guidelines, Interna