Saad Issa Sarsam*1 Mohamed Fadhel Suliman2

1Professor, Department of Civil Engineering, University of Baghdad, Iraq

*Corresponding author, email: saadisasarsam@coeng.uobaghdad.edu.iq 2Department of Highways, University of Al-Mustansiria, Baghdad, Iraq

email: engsaad09@yahoo.com

Abstract #

Microcracking of rigid pavement usually occur due to the shrinkage of concrete after casting or throughout its service life due to repeated compressive, tensile, and shear stress. Such cracking exhibit a durability problem since the ingress of moisture and harmful chemicals such as sulphates and chlorides into the concrete through the cracks can cause premature matrix degradation and corrosion of embedded steel reinforcement, which may result in the decrement of strength and life. In this work, implementation of self- healing techniques was adopted with the aid of bacteria and healing agent to precipitate CaCo3 on the formed micro-cracks. The precipitation of calcite by continuous hydration of cement helps in production of calcium carbonate precipitation with the help of bacteria. A soil bacterium named Bacillus subtilis was cultured in the laboratory, the concentration of bacteria cell of B. subtilits in normal saline (NaCl, 9 g/l) suspension was 106 cell/ml. Concrete specimens of various type (cube of 100x100x100 mm, cylinder of 100mm diameter and 200mm height, and beam of 100 x 100 x 500 mm) size have been prepared in the laboratory, then separated to three sets. The first set of specimens were subjected to controlled compression and flexure pre-cracking, then subjected to healing and curing in a water bath which contains the prementioned bacteria at 20°C for 7 days. The second set was the control specimens cured in water bath for 7 and 28 days at 20°C. The third set of specimens were subjected to healing and curing in a water bath which contains the prementioned bacteria at 20°C for 7 and 28 days and then tested for compressive, indirect tensile, and flexure properties. It was observed that the healing process provided by the bacteria have improved the overall properties of concrete by (23, 10.7 and 16) % for compressive, tensile and flexure strength respectively as compared to those of control mixture after 28 days of curing. On the other hand, specimens subjected to controlled pre-cracking exhibit improvement in strength properties after the healing process provided by the bacteria by (28 and 33) % for compressive and flexure strength respectively as compared to those of control mixture after 7 days of curing. It was concluded that implementation of the healing concept of cracking with the aid of bacteria is beneficial and can be considered as sustainable and environment friendly solution for maintenance.

Keywords:

Maintenance, concrete, bacteria, healing, pre-cracking, pavement

1 Introduction #

Concrete is the most commonly used material for construction of rigid pavement for airport and major arterials in Iraq. Micro Cracks usually occurs due to various mechanisms such as temperature gradient of thick pavement, repeated loading, shrinkage after casting, and Freeze-thaw cycles. Maintenance of cracks of macro size is a routine work, but the problem arises when micro cracks exists as stated by Sarsam, [10]. Cracks tend to expand further and eventually require costly repair. If micro cracks grow and reach the reinforcement, the reinforcement may corrode when it is exposed to water and oxygen and possibly carbon dioxide and chlorides (indirect degradation) as reported by Nivedhitha, et al, [6]. Research has shown that autogenous healing happens due to hydration of non-reacted cement particles present in the concrete matrix when encounters ingress water resulting in closure of micro cracks, the inbuilt bacteria-based self- healing process was found to heal cracks completely up to 0.5 mm width, Rao et al, [9]. Novel technique has been developed by using a selective microbial metabolic activity promote calcium carbonate (calcite) precipitation, Karthik and Rao, [4]. At the point when broken segment blended in microscopic organisms interacts with fresh concrete, cracked surfaces are enacted within the sight of water, and after that starts to multiply and precipitate minerals. These minerals, including calcium carbonate close the crack. The microscopic organisms should act as an impetus and change an antecedent compound, for example, calcium carbonate-based mineral accelerates, into an appropriate filler material, Vipu et al, [13]. Bacterial concrete helps in increase the strength of concrete by the action of calcium precipitation of bacteria and it proves to be cost effective. Bacterial concrete increases compressive strength up to 20%. The economical dose found by analysis is 10 ml that helped to make bacterial concrete quite economical. The cost of bacterial concrete increased 7-15% more than conventional concrete, Patil et al, [7]. It was stated by Prabakar et al, [8] that the use of bacterial concrete is one of the ecofriendly techniques for crack healing. This technique uses the calcium precipitate produced by bacterial metabolic activities to heal cracks. Bacterial concrete shows greater strength and durability than normal concrete. The addition of bacillus Subtilis bacteria showed significant improvement in the compressive, split tensile and flexural strength than the conventional concrete. From the above it can be concluded that bacteria can be easily cultured and safely used in improving the strength characteristics of concrete, Sarsam et al, [11]. The outcome of a study by Schlangen et al, [12] shows that crack healing in bacterial concrete is much more efficient than in concrete of the same composition but without added biochemical healing agent. The reason for this can be explained by the strictly chemical processes in the control and additional biological processes in the bacterial concrete. It was concluded by Bhagyashri et al, [2] that the greatest improvement in compressive strength occurs at cell concentrations of 105 cells/ml for all ages. The study showed that a 25% increase in 28-day compressive strength of cement mortar was achieved. Enhancement of compression strength, reduction in permeability, water absorption has been seen in various cementitious and stone materials. The nutrients for the bacteria which can precipitate calcite are calcium sources, phosphorous and nitrogen sources. These bacterial components remain dormant in concrete, when the seepage of water take place into the formed cracks helps in reacting with the nutrient to precipitate calcite i.e., CaCo3, Breugel, [3]. Bacterial induced calcium carbonate deposition has been proposed as an alternative and environmentally friendly crack repair and self-healing technique. The precipitation of Ca Co3 helps in sealing the micro cracks. It concluded by Krishnapriyaa et al, [5] that bacteria are suitable for use in concrete as it had resulted in increased strength and complete healing of cracks in concrete specimens. The inclusion of these bacteria in concrete will result in high strength, crack free and durable concrete structures in the future.

Based on the above introduction, the present investigation will consider implementation of Bacillus subtilis in the curing water of concrete to study its influence on the compressive, tensile, and flexural strength of concrete before and after pre-cracking.

2 Material Characteristics #

2.1 Cement #

The Iraqi Ordinary Portland cement (type 1) with a commercial name of (Tasluga) was implemented throughout the present work. Table 1 exhibit the chemical composition of cement, while Table 2 presents the physical properties of cement.

| Oxide | % by weight | Limit of Iraqi specification No.5/ 1984 |

| CaO | 61.28 | ——– |

| SiO2 | 18.372 | ——– |

| Al2O3 | 3.58 | ——– |

| Fe2O3 | 5.02 | ——– |

| MgO | 1.39 | < 5.0 |

| SO3 | 2.02 | < 2.80 |

| C3A | 0.988 | ——– |

| Loss on ignition | 2.85 | ≤ 4.0 |

| Insoluble residue | 1.07 | < 1.5 |

| Lime saturated Factor | 1.0148 | ≥ 0.66 ≤ 1.02 |

Table 1. Chemical composition of cement

| Physical properties | Test result | Limits of Iraqi specification |

| Specific surface area, Blain’s method m²/kg | 394 | ≥ 230 |

| Soundness, Autoclave’s Method, % | 0.03 | < 0.8 |

| Setting time, Vicat’s method | ||

| Initial setting hour: min | 2:15 | ≥ 45 min |

| Final setting hour: min | 3:30 | ≤ 10 hours |

| Compressive strength | ||

| 3 days N/mm² | 20.7 | ≥ 15 |

| 7 days N/mm² | 26.1 | ≥ 23 |

Table 2. Physical properties of cement

2.2 Aggregate #

Crushed gravel with a nominal size of (19 mm) was obtained from Nibaee region and used in this work. The properties of coarse aggregate are shown in Table 3. Fine aggregate of maximum size 4.75mm was obtained from Al-Ukhaider quarry and used, the properties of fine aggregate are shown in Table 3. The combined gradation implemented is illustrated in Table 4.

| Type of aggregate | Bulk Specific Gravity | Density(kg/m³) | Absorption % | SO3 % |

| Crushed aggregate | 2.63 | 1646 | 1.167 | 0.034 |

| Fine aggregate | 2.5 | 1789 | 9.3 | 0.126 |

Table 3. Properties of coarse and fine aggregates

2.3 Water #

The water used in mixes was drinking water of Baghdad area. This water was also used for curing.

| Sieve size mm | 19 | 12.5 | 9.5 | 4.75 | 1.18 | 0.3 | 0.15 |

| Percentage finer by weight | 100 | 85 | 70 | 59 | 46.4 | 16 | 3.3 |

Table 4. Combined gradation adopted

3 Methodology #

The methodology implemented in this investigation consist of three steps, in the first step, Culture and growth of bacteria (Bacillus subtilis) in the laboratory was conducted. The second step was preparation of concrete specimens (cubes, cylinder and beams), and pre-cracking was applied for cubes and beam specimens. In the third step, curing of the specimens was conducted in bacterial water then the strength properties of concrete specimens were evaluated after seven and 28 days of curing.

3.1 Preparation, Isolation and Culture of Bacteria Bacillus Subtilis #

The isolation and culture of bacteria bacillus subtilis starts by collection of soil samples from Agricultural areas in Baghdad city and evacuation in glass bottles. The soil sample was then mixed with distilled water and shaken vigorously to ensure thorough mixing. Serial dilution was made by transfer of 1 ml of soil suspending to 9 ml of distilled water in test tube, this soil suspension is of 10-1 dilution. After mixing this solution in vortex mixer, one ml of 10-1 dilution was transfer to 9 ml of distilled water, then the concentration of solution becomes 10 -2 dilutions. This process was repeated until 10-6 dilution is obtained. After all these steps, petri-dishes plates with nutrient agar media according to the bacteria requirement have been prepared. The solution of concentration 10-4 to 10-6 was spread by cotton swab on the petri-dishes plate with nutrient agar media in it and incubated in 37 °C to 24 hours in the incubator. After 24 hours, the plates are taken out from incubator, the type of colony formation in the Petri dish plate was checked. Some more petri-dishes plates with the same media and soil sample with different concentration have also been prepared. After this, the different type of colonies on different plates were observed and the growth after 24 hours incubation was checked. The morphology of different colonies was checked by gram staining method. The urease test method and vitek 2E compact system have been implemented for identification of bacillus subtilis. Afterword, Preparation of the concentration 10 6 of bacterial cell (bacillus

subtilis) starts by Transfer of loop full of single colonies of bacillus subtilis that form urease enzyme from nutrient agar to brain heart broth media and incubation at 37 °C on shaker at 150 rpm for 24 hours. The harvest of bacterial cell was done by centrifuge the 24 hour’s old grown culture (5000 rpm, 5 minutes). The sediments (bacterial cell) was form after centrifuge and were re-suspended in normal saline (NaCl, 9 g/l). The concentration of bacteria cell of bacillus subtilits in suspension was 106 cell/ml. Figure 1 exhibit the isolation of the bacteria, while Figure 2 shows the culture and dilution of the bacteria.

Figure 1. Isolation of the bacteria.

Figure 2. Culture and dilution of the bacteria

3.2 Preparation of Concrete Mixture #

Control concrete mixture was designed as per ACI 211.1-91, [1] method, such mixture is usually used for rigid pavement construction. The mix proportion is (1:1.5:3.75) with 0.45 water cement ratio. Cube, beam and cylinder specimens have been prepared, covered with polythene sheets to retain the mixing water for curing for 24 hours. Specimens were immersed in water with bacterial concentration of 106 cell/ml of water. Calcium lactate of 5% by weight of cement were added to the bacterial water. Specimens were tested after seven and 28 days to assess the impact of curing in bacterial water on the physical properties.

3.3 Pre-cracking of specimens #

To simulate the concrete condition during service in the field, and to determine the effectiveness of bacteria in the crack healing process, specimens were subjected to controlled pre-cracking in the laboratory. Many trial specimens have been subjected to various compression and flexural loading, then tested for strength to check that it does not reach the failure condition. Cube specimens were subjected to pre-cracking after 24 hours of curing, a load of 260 kN was applied for one minute then released. Cube specimens were subjected to ultrasonic wave traverse with the aid of pundit to determine the time required for the sound to traverse the specimen before and after the pre-cracking process. For beam specimens, the pre-cracking was conducted using a flexure load of 5kN, while the ultrasonic wave traverse along the length of the beam. The time required for the sound to traverse the specimen before and after the pre-cracking process was recorded.

4 Results and Discussion #

4.1 Ultrasonic Wave Traverse Time #

Cubes and beam specimens have been subjected to ultrasonic wave traverse time determination before and after pre-cracking process and after bacterial curing to assess the influence of bacterial curing in the crack healing process. Control specimens were also tested for comparison. Figure 3-a exhibit the impact of bacterial curing on the ultrasonic wave traverse time for cube specimens. It can be observed that longer time was required to traverse the control cube specimen as compared to bacterial curing cube before pre-cracking, this may be attributed to the lower voids after bacterial curing due to precipitation of CaCo3. After pre-cracking, the time taken by ultrasonic wave to traverse the cube was higher by (110 and 150) % for control and bacterial cured cubes respectively as compared to the case before pre-cracking. After seven days of curing, the variation of the ultrasonic wave traverse time was not significant among control and bacterial cured cubes. This could be attributed to the possible autogenous healing happens due to hydration of non-reacted cement particles present in the concrete matrix when encounters ingress water resulting in closure of micro cracks as mentioned by Rao et al, [9]. On the other hand, the curing period of seven days was effective in healing the microcracks for both control and bacterial cured cubes and the ultrasonic wave traverse time was almost equivalent to that before pre-cracking condition. Figure 3-b exhibit the impact of bacterial curing on the ultrasonic wave traverse time for beam specimens. After pre-cracking, the time taken by ultrasonic wave to traverse the beam was higher by (20) % for control and bacterial cured beams respectively as compared to the case before pre-cracking. After and before seven days of curing, the variation of the ultrasonic wave traverse time was not significant among control and bacterial cured beams. This may be explained that on the surface of control concrete, calcium carbonate will be formed due to the reaction of CO2 present with calcium hydroxide present in the concrete matrix. The curing period of seven days was effective in healing the microcracks for both control and bacterial cured beams and the ultrasonic wave traverse time was 8% lower than that of after pre-cracking condition.

Figure 3. Ultrasonic wave traverse time for pre-cracked specimens

Figure 4. Ultrasonic wave test process

4.2 Strength Properties After Pre-Cracking #

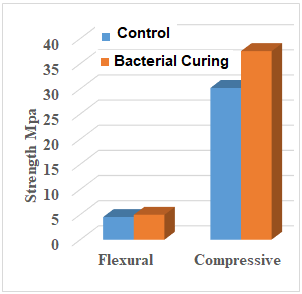

Six cubes are tested after a curing period of 7days, 28days, for every age period 3 cubes are casted. Control cubes were also prepared and tested for comparison. The size of cube is (100x100x100) mm. Beam specimens of (100 x 100) mm of section and 500 mm length have been prepared and tested in duplicate. Figure 5 exhibit the flexural and compressive strength of the pre-cracked specimens after seven days of curing in bacterial water, it can be noticed that the compressive strength increases by 28.5 %, while the flexural strength increases by 33 % after curing in bacterial water for seven days.

Figure 5. Strength properties after pre-cracking and curing for seven days

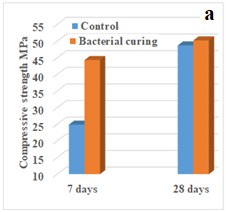

4.3 Specimens for Compressive Strength Test #

Figure 6 shows the compressive strength determination of cube specimen. The compressive strength test results for both conventional and bacterial cured concrete are shown in Figure 8-a. It can be observed that the bacterial cured concrete exhibit high compressive strength when compared to that of control concrete. The variation was (107 and 23) % after 7 and 28 days of curing respectively. On the other hand, the increment in compressive strength after 28 days of curing was (95.5 and 18.4) % for control and bacterial concrete respectively.

4.4 Specimens for Splitting Tensile Test #

Figure 7 shows the Indirect (splitting) tensile strength determination of cylinder specimen. The test is carried out after casting and curing cylindrical specimens of dimension 100mm diameter and 200mm height, specimens were tested for indirect tensile strength. The load was applied until failure of the specimen along the vertical diameter. The tensile strength was calculated based on the failure load. It can be noticed from Figure 8-b that the bacterial cured concrete exhibit high tensile strength when compared to that of control concrete. The variation was (5 and 10.7) % after 7 and 28 days of curing respectively. On the other hand, the increment in tensile strength after 28 days of curing was (8.3 and 14.2) % for control and bacterial cured concrete respectively.

Figure 6. Compressive strength test

Figure 7. Indirect Tensile strength test

Figure 8. Compressive and Tensile Strength of pre-cracked specimens

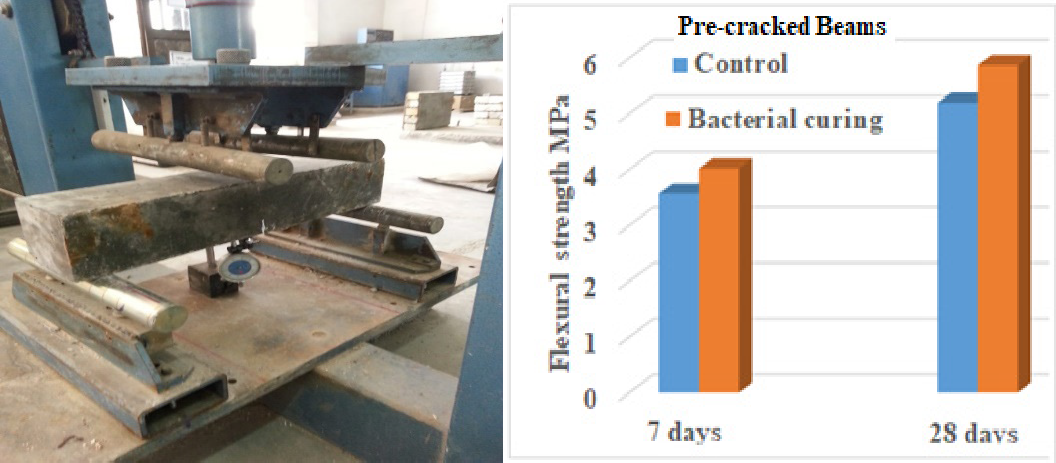

4.5 Specimens for Flexural Strength Test (four-point loading) #

The test is carried out after casting and curing beam specimens in bacterial water to find the flexural strength of the concrete. Control specimens were also prepared and tested for comparison. The beam specimens were placed in the machine in such manner that the load is applied to the uppermost surface as cast in the mold. Two points loading was adopted on an effective span of 450 mm while the beam rest on two supports. The load is applied until the failure. Figure 9 exhibit the flexural strength setup while Figure 10 shows the flexural strength of control and bacterial cured concrete. It can be noticed that the bacterial cured concrete exhibit high flexural strength when compared to that of control concrete. The variation was (22.5 and 16) % after 7 and 28 days of curing respectively. On the other hand, the increment in flexural strength after 28 days of curing was (38 and 48.7) % for control and bacterial cured concrete respectively. Such behavior may be attributed to the micro crack healing by precipitation of CaCO3 in the microcracks.

Figure 9. Flexural strength test Figure 10. Flexural Strength of specimens

5 Conclusions #

Based on the testing program, the following conclusions can be drawn

- Implementation of bacteria (Bacillus subtilis) in the curing water exhibit a positive influence on the strength properties of concrete.

- Bacterial cured concrete exhibit high compressive strength of (107 and 23) % after 7 and 28 days of curing respectively when compared to that of control concrete. The increment in compressive strength after 28 days of curing was (95.5 and 18.4) % for control and bacterial concrete respectively.

- Bacterial cured concrete exhibit high tensile strength of (5 and 10.7) % after 7 and 28 days of curing respectively when compared to that of control concrete. The increment in tensile strength after 28 days of curing was (8.3 and 14.2) % for control and bacterial concrete respectively.

- Bacterial cured concrete exhibit high flexural strength of (22.5 and 16) % after 7 and 28 days of curing respectively when compared to that of control concrete. The increment in flexural strength after 28 days of curing was (38 and 48.7) % for control and bacterial concrete respectively.

- Specimens subjected to controlled pre-cracking exhibit improvement in strength properties after the healing process provided by the bacteria by (28 and 33) % for compressive and flexure strength respectively as compared to those of control mixture after 7 days of curing in bacterial water.

References #

- ACI 211.1-91 Reapproved “Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete”. American concrete institute. (2009).

- P. Bhagyashri, Archana m., Megh b., Sayali p. “Bacterial Concrete”. Journal of information, knowledge and research in Civil Engineering Nov. 16 to Oct 17, Volume 4, Issue 2. (2017).

- K. V. Breugel “Self-healing material concepts as solution for aging infrastructure”. Proceedings, 37th conference on our world in Concrete & Structures, August, 29-31, Singapore. (2012).

- C. Karthik and Rao R. “Properties of Bacterial-based Self-healing Concrete- A review”. International Journal of Chem. Tech. Research, Vol.9, No.02 pp 182-188. (2016).

- S. Krishnapriyaa, Babub V., Arulraj P. “Isolation and identification of bacteria to improve the strength of concrete”. Microbiological Research, 174 pp. 48–55. (2015).

- M. Nivedhitha, Hussain Z., Hidhaya F., “Devi A. Evaluation of Bio calcification and Strength Aspects in Bacterial Concrete with Bacillus Subtilis”. International Journal of Engineering Research & Technology (IJERT). November, Vol. 5 Issue 11. (2016).

- G. Patil, Mali D. and Pawar M. “Efficiency of bacterial concrete”. International Journal of Modern Trends in Engineering and Research (IJMTER), Volume 04, Issue 3, March. (2017).

- J. Prabakar, Singh J., Somasundaram T., Aiswarya S. “An overview of viable use of bacterial concrete for crack healing”. International Journal of Advanced Research Methodology in Engineering & Technology, May, Volume 1, Issue3. (2017).

- M. Rao, Reddy S., Hafsa M., Veena P., and Anusha P. “Bioengineered Concrete – A Sustainable Self-Healing Construction Material”. Research Journal of Engineering Sciences, Vol. 2(6), 45-51, June. (2013).

- S. I. Sarsam “Influence of Nano Materials Addition as Partial Replacement of Cement in the Properties of Concrete Pavement”. Journal of Nano science and Nano engineering, public science framework, American institute of science, Vol. 2, No. 1, pp. 1-5. (2016).

- S. I. Sarsam, Mahdi LH, Suliman MF, Ali HA. “Influence of Induced Bacteria Cell on the Strength Properties of Concrete”. Journal of Advances in Civil Engineering and Construction Materials; 1(1): 16-25. Unique Pub International (UPI). (2018).

- E. Schlangen, Jonkers H., Qian S., Garcia A. “Recent advances on self -healing of concrete”. Proceedings of Concrete and Concrete Structure- Recent Advances in Fracture Mechanics of Concrete. FraMCoS-7, May 23-28. (2010).

- P. Vipu Solanki, Dave S., Trivedi N. “State of Art Review on Bacterial Concrete” International Journal for Research in Applied Science & Engineering Technology (IJRASET). Volume 5 Issue XII December. (2017).