Rami Alsodi1,3, Mufid Samarai2,3

- Department of Public Works, P.O. Box 351, Sharjah, UAE. rami.alsodi@dpw.sharjah.ae

- Sahara Management Consultancy, P. O. Box 2580, Dubai, UAE. samarai@sharjah.ac.ae

3 University of Sharjah, P. O. Box 27272, Sharjah, UAE. U21200094@sharjah.ac.ae

Abstract #

The 4th Industrial Revolution is driving the convergence of digital and physical technologies, reshaping industries globally. Even the traditionally conservative construction sector is embracing digitalization and automation. In this context, the paper addresses the state of maintenance and engineering education, focusing on the concrete building maintenance sector. This industry demands a workforce skilled in navigating the new technological landscape. However, traditional engineering education often lags behind technological advancements, leaving graduates unprepared to tackle evolving challenges. The decline in civil engineering students and the lack of emphasis on maintenance education in study plans further exacerbate this issue. On the other hand, the building maintenance market is expanding rapidly, indicating a demand for well-educated maintenance professionals. The paper proposes a comprehensive framework to reshape maintenance education by updating curricula, encouraging industry collaboration, and improving public awareness. It emphasizes integrating emerging technologies, interdisciplinary collaboration, practical experience, and lifelong learning to equip graduates for modern maintenance challenges.

Keywords: Maintenance, Education, Fourth Industrial Revolution.

1 Introduction #

In the context of the fourth industrial revolution and its resonance with concrete building maintenance, this research paper initiates an exploration of the dynamic transformation of education and technologies in this field. Embracing these changes emerges as a catalyst for educational progress, catering to emerging requisites, and fostering a competitive pursuit of excellence.

Engineering stands as a vanguard in this transformative landscape, intricately woven into the fabric of societal demands, spanning housing, construction, and everyday necessities. Yet, the rapid evolution driven by the fourth industrial revolution demands a corresponding evolution in education paradigms, particularly in maintenance and engineering. The ability to anticipate impending needs and seamlessly adapt to emerging trends becomes a hallmark of a responsive education system, ensuring relevance in the face of rapid change.

This underscores the importance for professional institutes and universities to cultivate an acute awareness of the dynamic interplay between evolving technology, industry dynamics, and market demand. Such awareness not only ensures a comprehensive education but also guarantees students a professionally secure future, characterized by stability, upward mobility, and the realization of personal aspirations [1].

Building Maintenance falls under the umbrella of Civil engineering disciplines. Civil engineering makes up to about 50 percent of all engineering graduates [2]. The profession faces significant and rapid changes due to technological advancement and challenges to public safety, health, and welfare are becoming more demanding [2].

In subsequent sections, we delve deeper into the implications of the fourth industrial revolution on concrete building maintenance and the evolving landscape of engineering education. Through rigorous analysis, we aim to illuminate the pivotal role of adaptability in education and practice, particularly within the Arab world’s engineering capacity.

2 Basics of Building Maintenance and Codes #

Maintenance refers to the process of preserving, repairing, and ensuring the proper functioning of an object, system, or infrastructure. From mechanical devices and computer systems to buildings and vehicles, maintenance plays a crucial role in maintaining functionality and extending the lifespan of various assets. Its importance cannot be overstated, as effective maintenance practices lead to improved safety, increased productivity, reduced costs, and overall sustainability. Hence the importance of maintenance lies in its ability to ensure the proper functioning of assets and prevent unexpected failures. For instance, regular maintenance of machines in a factory prevents breakdowns, minimizes downtime, and maximizes production output. Similarly, maintaining the structural integrity of buildings, such as bridges and hospitals, guarantees the safety of occupants and prevents catastrophic accidents.

Moreover, maintenance contributes to cost reduction by minimizing the need for costly replacements or repairs. By addressing issues at their early stages, maintenance professionals can identify potential problems and rectify them before they escalate into major breakdowns or failures. This approach saves businesses and individuals substantial amounts of money that would otherwise be spent on expensive replacements or emergency repairs. As a matter of fact, building stocks are considered a national asset, they are the main representation of civilization and development in any country. The design and construction of buildings have come a long way in terms of new technologies and techniques to build strong and durable buildings with long-term serviceability. However, buildings cannot maintain their original state throughout their lifetime and some deterioration is inevitable [9]. Here comes the building maintenance management role as a versatile engineering tool to sustain the building’s integrity and extend its life span.

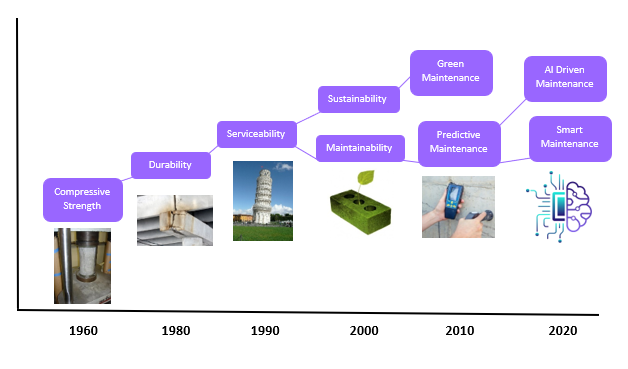

The interest in maintenance wasn’t a concern in the early stages of concrete development. In the 1960s, only the compressive strength of concrete was considered the most important parameter, then durability became more important in the 80s. 20 years later, the interest shifted toward serviceability and sustainability. Nowadays, new technologies and techniques are emerging, involving artificial intelligence, machine learning, and automation. Fig.1 is a visual representation of the development of interest in concrete and maintenance.

Fig. 1 Interest in Maintenance development through the years

Applying correct maintenance and repair principles has proven to have a positive impact economically and environmentally [10,11].

Maintenance is an essential aspect of various industries and sectors. By preserving and repairing assets, maintenance professionals ensure their proper functioning, enhance safety, reduce costs, and contribute to sustainability. As technologies continue to advance, incorporating effective maintenance practices becomes increasingly necessary, emphasizing the importance of this discipline.

In order to provide a safe and functional environment, building maintenance and adherence to codes are of paramount importance. Whether it is a residential home, office building, or commercial facility, proper maintenance and compliance with codes are essential to ensure the longevity and safety of the structure. In this essay, we will explore the basics of building maintenance and codes, outlining their significance and how they contribute to a well-maintained building. Building maintenance refers to the activities undertaken to preserve the condition of a building and its systems. This includes routine inspections, repairs, and any other actions necessary to uphold the structural integrity and functionality of the building. Adequate maintenance not only prevents minor issues from escalating into major problems but also helps extend the life of the building and its components. Furthermore, it ensures the safety and comfort of the occupants, making it indispensable for any responsible building owner or manager.

On the other hand, building codes are a set of standards and regulations established by local authorities that dictate the minimum requirements for the design, construction, and maintenance of structures. These codes aim to safeguard the health, safety, and welfare of the inhabitants and the surrounding community. They cover aspects such as fire safety, structural stability, electrical wiring, plumbing systems, and accessibility for people with disabilities. By adhering to building codes, builders and property owners contribute to the overall safety and functionality of the community.

Regular inspections and maintenance are imperative to identify and rectify potential issues in a building. These inspections may cover various aspects, including structural integrity, electrical systems, plumbing systems, HVAC (heating, ventilation, and air conditioning), and safety equipment such as fire alarms and extinguishers. Maintenance personnel should monitor and maintain these systems regularly to address any emergent problems and ensure optimal performance.

While building maintenance is crucial for the proper functioning of a building, adherence to building codes is equally important. Codes offer a standardized framework for construction and maintenance, guaranteeing a minimum level of safety and quality. When constructing or renovating a building, it is vital to consult with architects, engineers, contractors, and other professionals familiar with local codes to ensure compliance. Failure to meet these codes can result in legal penalties, pose serious risks to occupants, and even lead to demolition or closure of the building. This is why it is crucial to understand the basics of the maintenance and rehabilitation of structures. BS 3811: 1984 defines maintenance as a combination of actions to retain or restore an item to an acceptable condition [12]. The Committee on Building Maintenance further defines maintenance as work done to keep, restore, or improve every part of a building and its surroundings to a currently acceptable standard, sustaining utility and value over time [13]. The usefulness of these definitions depends on the purpose of the assessment, whether it is economic or operational. In general, building maintenance and repair refers to all procedures aiming to keep a building in proper working condition, preserve its structural integrity, and ensure a safe and functional environment for its occupants.

Maintenance practices and dealing with buildings failure date to ancient ages. One of the earliest written references to building maintenance can be found in the Code of Hammurabi, an ancient Babylonian legal code dating back to around 1754 BCE [14]. Many codes and standards have been developed in this regard including ACI 562-19, and ACI 201.1R, British Standard (BS) 8210, European Standard EN 15221, ISO 41001. Such codes standardized the basics of the assessment and evaluation of concrete buildings including visual inspection and nondestructive testing. It also discussed types of deterioration, cracking, corrosion of reinforcement, repairing techniques, and testing of repair material. Failure in concrete structures is often caused by environmental attacks and intrinsic changes in the concrete.

Maintenance of structures aims to prevent damage and decay, as well as repair defects and strengthen the structure if necessary. Maintenance work is classified as the following:

- Preventive maintenance is the work done before defects occur or damage develops in the structure.

- Remedial maintenance which is the maintenance done after the defects or damage occur in the structure.

- Routine maintenance, which is the service of maintenance attended to the structure periodically.

- Special maintenance which to meet new conditions of usage or to increase its serviceability.

The assessment of in-situ concrete structures requires testing for various purposes, such as prior to renovation, diagnosing deterioration, regular inspection, or resolving quality disputes.

Repairing damaged structures is more complex than new construction. Considerations include reviewing construction records, thorough visual inspection, and using photography to document the condition. Clearly defining test objectives and selecting appropriate test types, locations, and frequencies to gather sufficient data while minimizing costs and structural damage.

The choice of test methods depends on the assessment’s purpose, whether it’s for strength, quality, integrity, durability, or identifying causes of deterioration. Combining multiple test methods can enhance result confidence, especially when consistent trends are observed.

Various test methods for estimating the in-situ strength of concrete can be classified into three categories:

- Destructive tests: These conventional methods involve taking cores or cubes from the concrete for strength measurement. However, they may not be feasible for slender members and can cause considerable damage to the structure. (Examples: Concrete Core Test, Concrete Cube Test, Flexural Strength Test)

- Non-destructive tests: These methods do not directly measure strength but estimate it by measuring other properties and using calibration. The advantage is that concrete remains undamaged during testing (Ultrasonic Pulse Velocity, Rebound Hammer Test, Concrete Maturity Test)

- Partially destructive tests: In these tests, concrete is tested to failure, but the resulting damage is localized, and the member under test is not significantly weakened (Pull-off Test, Windsor Probe Test, Core Pull-out Test).

After a full evaluation of the damage comes the repair stage. One of the most common concrete repair methods is patching the damaged area. This process may involve multiple stages, and selecting the appropriate material for reinstating the cover can be challenging. Typically, options include cementitious, polymer-modified cementitious, or resin mortars, with preference given in that order as the patch thickness decreases. Ensuring a strong bond to the concrete substrate is crucial in the repair process. Additionally, evaluating the compatibility between the repair material and the original concrete in terms of resisting structural loading, thermal and creep effects, and assessing the level of composite action between the two materials are vital considerations for successful concrete repair.

Understanding the definition and types of maintenance, Common test types and repair methods should be the backbone of any maintenance training program or educational course.

3 Structural Health Monitoring of Concrete Structures #

Structural Health Monitoring (SHM) is a field of technology and engineering that involves continuously monitoring the condition and performance of structures such as buildings, bridges, dams, pipelines, and other infrastructure.

Evaluating a structure manually at regular time intervals can result in high expenses and demand significant labor efforts. However, the progress in sensor technologies, wireless communication, data processing methods, and artificial intelligence, accompanied by the increasing number of aging structures and the imperative to cut down on maintenance expenditures, paved the way for more autonomous methods [15]. Sensors embedded within concrete structures collect real-time data on factors like temperature, moisture levels, and structural stresses, enabling predictive maintenance strategies. Through this data collection sensors can be used to detect cracks, delamination, fatigue, fiber breakage, initial freeze-thaw damage, and corrosion [16-25]. The following are common sensor types used in (SHM):

Fiber Optics Sensors: Use light signals to measure changes in strain, temperature, and other parameters within concrete structures. They are highly sensitive and can provide real-time data on deformation and temperature variations. Fiber optic sensors are ideal for monitoring structural health and detecting early signs of damage like cracks.

Piezoelectric Sensors: Convert mechanical stress or vibrations into electrical signals. These sensors are used to monitor dynamic behavior, such as vibrations, impacts, and forces on concrete structures. They are valuable for assessing structural integrity, detecting structural shifts, and studying the effects of external loads.

Electrochemical Sensors: Measure the electrical properties of concrete to monitor corrosion and other chemical reactions. They can detect the presence of corrosive ions and assess the likelihood of reinforcing steel corrosion.

Self-sensing concrete: Incorporates conductive materials (such as carbon nanotubes) that can change their electrical properties in response to stress or deformation. This allows the concrete itself to act as a sensor, providing real-time feedback on structural changes. Self-sensing concrete is particularly useful for detecting micro-cracks and assessing structural health over time.

Wireless Sensors: Utilize wireless communication networks to transmit data from various sensors placed within concrete structures. They provide the advantage of remote monitoring, enabling real-time data collection without the need for extensive cabling. These are not direct concrete evaluation sensors however they play a crucial role in the Fourth Industrial Revolution that will be discussed later.

4 Current State of Maintenance and Engineering Education #

The 4th Industrial Revolution, characterized by the fusion of digital and physical technologies, is reshaping industries worldwide. The construction sector, historically conservative, is now embracing digitalization and automation. Concrete building maintenance, a cornerstone of the industry, requires a workforce equipped with the skills to navigate this new technological landscape.

Traditional engineering education has often lagged behind technological advancements. Graduates are not always adequately prepared to address the challenges posed by evolving industries [3]. This is particularly true for concrete building maintenance, where outdated methodologies may hinder effective maintenance practices.

According to the UNESCO Report on Engineering Education [2], statistics indicate a decline in the number of students choosing civil engineering as a career due to obsolete study plans perceived high work commitment, perceived low salaries, and a lack of research careers. The civil engineering program is the backbone of maintenance education due to the prerequisite of gaining basic concrete and structural knowledge in this field.

On the other hand, the global market size for building maintenance is increasing at a CAGR of 8.24% and it is expected to increase to USD 612983.7 million by 2028 [4]. Corrosion alone has a global annual cost of $2.5 trillion annually [5]. These numbers indicate that the demand for skilled and well-educated labor in the maintenance field is highly required.

Moreover, study plans in civil engineering schools around the world lack an emphasis on both new technologies as well as maintenance education. Topics on machine learning and artificial intelligence are usually addressed only at higher levels of education. Maintenance courses, if available, are offered as elective courses.

Therefore, updating concrete building maintenance education in terms of availability and methodologies is crucial to producing graduates who are adept at utilizing emerging technologies.

5 Challenges Facing Fourth Industrial Revolution Education #

The merging of the fourth industrial revolution tools such as artificial intelligence machine learning with the current education is a challenging task with many expected obstacles that must be tackled by academics, educators, professionals, and decision-makers.

Acceptance of these methods is challenging for as many educators as possible, and students might be hesitant to embrace AI-driven tools due to concerns about job displacement, lack of personalization, or a belief that technology cannot replace human interaction in education [6].

Another aspect is the lack of expertise in the current educational and professional institutes. Implementing AI in education requires collaboration between educators, technologists, and researchers. However, there is often a shortage of experts who can bridge the gap between these domains. AI Readiness of educators needs to be an active, participatory training process and aims to empower their abilities to be more able to leverage AI to meet education needs [7].

Overcoming resistance and fostering acceptance while providing expert skills to the industry is a significant challenge.

Other concerns are related to Data Privacy and Cyber Security as well as providing quality data. AI in education often involves collecting and analyzing student data. Ensuring the privacy and security of this data is crucial, as it may contain sensitive information. Also providing quality high-quality datasets is crucial for the overall quality of results and learning [8].

Finally, Integrating AI into education involves challenges related to cost and infrastructure in order to develop or acquire the required AI tools, train educators, and update infrastructure. In engineering, it is required to provide high-quality sensors, robotic components, high-efficiency computers, and sophisticated software. All of these Many educational institutions, especially in underfunded areas, may struggle to allocate resources for these purposes.

6 Comprehensive Framework to Reshape Maintenance Education #

As new technologies reshape industries, it is imperative that concrete building maintenance education evolves accordingly. The proposed framework herein integrates technology, interdisciplinary collaboration, practical experience, and lifelong learning to equip graduates with the skills needed for modern maintenance challenges. While challenges exist, the potential benefits to both professionals and educators in the construction industry are substantial. By embracing these changes, educational institutions can ensure that graduates and future engineers contribute effectively to the sustainable and technologically advanced future of concrete building maintenance.

6.1 Update Current Education Programs

Revise the curricula of maintenance and engineering programs to include comprehensive coverage of emerging technologies, such as artificial intelligence, machine learning, robotics, and data analytics. Integrate these topics at various levels of education, ensuring that students receive exposure to these concepts from the early stages of their academic journey.

Furthermore, advocate for funding allocation to support the development of AI-focused infrastructure, including advanced computing resources, sensor systems, and robotic components. Seek collaborations with industry, government, and philanthropic organizations to ensure adequate resources are available for effective implementation.

Moreover, integrate modules on data privacy, cybersecurity, and ethical considerations related to AI implementation. Ensure students are well-versed in handling sensitive data, complying with regulations, and making ethical decisions when using AI tools for maintenance purposes.

Finally, in this regard, establish comprehensive training programs for educators to enhance their understanding of AI technologies and their application in maintenance. This includes workshops, seminars, and collaborative projects with industry experts, ensuring educators stay updated and capable of imparting relevant knowledge to students.

6.2 Encourage Collaboration with the Industry

Facilitate collaboration between engineering faculties, computer science departments, and industry professionals to design interdisciplinary courses that bridge the gap between engineering principles and technological advancements as well as industrial needs. This collaborative approach will expose students to real-world challenges and encourage innovative problem-solving.

Emphasize practical learning experiences, including real projects, internships, and case studies that require students to apply theoretical knowledge to real-world maintenance scenarios. Partnerships with the industry can offer access to industry datasets, mentoring, and potential employment opportunities, which will lead to fully utilizing artificial intelligence capabilities.

6.3 Improve Public Awareness

Launch awareness campaigns to communicate the benefits of AI integration in maintenance education to the broader public. Address misconceptions and concerns, highlighting the potential for improved maintenance practices, job opportunities, and contributions to sustainable development.

Moreover, Incorporate discussions on the ethical implications and societal impacts of AI-driven technologies. Foster a comprehensive understanding of how AI can complement human expertise rather than replace it, addressing concerns about job displacement and encouraging a positive perception of AI’s role in education and maintenance.

7 Fourth Industrial Revolution Applications in Maintenance #

The Fourth Industrial Revolution, often referred to as Industry 4.0, is characterized by the fusion of digital, technologies, leading to unprecedented advancements in various industries. The integration of digital technologies in concrete maintenance can revolutionize traditional processes, leading to more efficient and sustainable solutions.

This revolution is marked by the convergence of advanced sensors, Internet of Things (IoT) devices, artificial intelligence (AI), and robotics. These new technologies can benefit from the basic understanding of electromagnetic properties, wave propagation, and transmission through concrete along with the advanced and continuous collection through special sensors.

In spite of notable progress in non-destructive testing (NDT), existing methods face a range of difficulties. The primary issue revolves around the examination and comprehension of a substantial volume of data obtained during testing, resulting in prolonged processes that rely on exceptionally skilled staff. Addressing this, artificial intelligence and machine learning present potential remedies for the complexities in data analysis and pattern identification. Moreover, the implementation of robotics, artificial algorithms, and network coding offers the possibility of reducing human errors by autonomously scrutinizing and detecting imperfections and anomalies [26].

7.1 Data Analytics through Machine Learning

Artificial Intelligence and Machine Learning can play a crucial role in processing vast amounts of data generated by monitoring sensors. AI algorithms can identify patterns, detect anomalies, and predict potential maintenance issues, allowing for proactive intervention before problems escalate. The ability of machine learning can save lots of time in recognizing patterns that are hard to detect with the naked eye when analyzing huge amounts of data sets.

These tools are essential for Predictive Maintenance as Machine learning models can analyze sensor data from structures to predict when maintenance is needed [27]. By monitoring factors like vibration, temperature, and moisture levels, these models can anticipate deterioration and recommend repairs before major issues arise.

These algorithms can help in Structural Health Monitoring where it can process data from various sensors placed on concrete structures to assess their overall health [28]. They can detect anomalies, shifts in load distribution, or signs of stress, allowing for timely intervention. It will also help in corrosion predictions by analyzing factors like exposure to salt, moisture, and temperature to predict the likelihood of corrosion, enabling proactive maintenance.

7.2 Image Recognition and Analysis

By using machine learning algorithms, practitioners can make use of prediction models to detect cracks in concrete more quickly and accurately through image recognition and analysis. Machine learning algorithms can be trained to detect cracks in concrete structures from images or sensor data. They can differentiate between harmless cracks and those that require immediate attention, improving the assessment process [29].

7.3 Optimization and Maintenance Schedules

Optimized Repair Scheduling: Machine learning can optimize repair schedules by considering various factors such as weather conditions, traffic patterns, and resource availability. This ensures that repairs are conducted at the most convenient and cost-effective times while minimizing environmental impact, reducing waste, and optimizing resource usage.

Machine learning models can also assist in estimating the costs associated with different repair scenarios. By considering factors such as labor, materials, and equipment, accurate cost projections can be made.

7.4 Internet of Things (IoT) devices

Internet of Things (IoT) devices have a significant impact on maintenance practices across various industries, including construction, manufacturing, transportation, and more. In the context of maintenance, IoT devices offer real-time data collection, analysis, and communication, enabling more proactive and efficient maintenance strategies [30].

The integration of IoT devices facilitates the creation of smart buildings, where interconnected systems optimize energy consumption, monitor structural health, and enable remote diagnostics and repairs.

IoT devices allow for remote monitoring of assets, which is particularly beneficial for infrastructure located in remote or hazardous areas. Maintenance teams can monitor equipment and structures from a central location, reducing the need for physical presence and minimizing risk.

Receiving real-time alerts and notifications is another integration of IoT systems in buildings. It can inform maintenance personnel or supervisors when anomalies or issues are detected. This allows for swift action and prevents potential problems from escalating.

7.5 Robotics

Robotics are another hallmark of the Fourth Industrial Revolution which is changing the landscape of building maintenance. Drones equipped with cameras and sensors can inspect structures for cracks, corrosion, and other defects in challenging-to-reach areas, eliminating the need for risky manual inspections. Autonomous robotic systems can perform routine maintenance tasks, such as cleaning facades and repairing minor damages, reducing the need for human intervention in hazardous environments.

These drones can be combined with machine learning abilities in data analysis to automate visual inspections of concrete surfaces. Cameras and drones equipped with image recognition algorithms can identify surface defects, erosion, and other issues [30].

8 Conclusion #

The 4th Industrial Revolution has ignited a transformation across industries through the fusion of digital and physical technologies. The construction sector, traditionally conservative, is now embracing digitalization and automation, particularly evident in concrete building maintenance. However, traditional engineering education often falls short of addressing these emerging challenges. Graduates frequently lack the skills to navigate the technological landscape, impeding effective maintenance practices. Moreover, declining interest in civil engineering as a career and the absence of emphasis on maintenance education in curricula exacerbate this issue. Conversely, the thriving building maintenance market underscores the demand for well-trained professionals. This paper advocates a holistic framework to revamp maintenance education, underscoring the need for updated curricula, industry partnerships, and public awareness campaigns. By incorporating emerging technologies, encouraging interdisciplinary collaboration, providing hands-on experience, and fostering continuous learning, educational institutions can ensure graduates contribute effectively to the future of concrete building maintenance in a sustainable and technologically advanced manner.

References #

- Minogue, K. (1973). The Concept of a University, London, Weidenfeld and Nicolson.

- Wall, K. (2010). Engineering: Issues, challenges and opportunities for development. Unesco.

- Miranda, J., Navarrete, C., Noguez, J., Molina-Espinosa, J. M., Ramírez-Montoya, M. S., Navarro-Tuch, S. A., … & Molina, A. (2021). The core components of education 4.0 in higher education: Three case studies in engineering education. Computers & Electrical Engineering, 93, 107278.

- PRWireCenter News. (n.d.). Building Maintenance Services Market Trend | Industry Forecast 2030. Barchart.com. https://www.barchart.com/story/news/19168424/building-maintenance-services-market-trend-industry-forecast-2030#:~:text=The%20global%20Building%20Maintenance%20Services%20market%20size%20was%20valued%20at,maintenance%20of%20systems%20and%20equipment.

- Annual global cost of corrosion: $2.5 trillion | globalspec. (n.d.). https://insights.globalspec.com/article/2340/annual-global-cost-of-corrosion-2-5-trillion

- Liang, Y., & Lee, S. A. (2017). Fear of autonomous robots and artificial intelligence: Evidence from national representative data with probability sampling. International Journal of Social Robotics, 9, 379-384.

- Luckin, R., Cukurova, M., Kent, C., & du Boulay, B. (2022). Empowering educators to be AI-ready. Computers and Education: Artificial Intelligence, 3, 100076.

- Jain, A., Patel, H., Nagalapatti, L., Gupta, N., Mehta, S., Guttula, S., … & Munigala, V. (2020, August). Overview and importance of data quality for machine learning tasks. In Proceedings of the 26th ACM SIGKDD international conference on knowledge discovery & data mining (pp. 3561-3562).

- Olagunju, R. E. (2012). Predictive modelling for sustainable residential building maintenance in developing countries: A Nigerian case. Interdisciplinary Journal of Contemporary Research in Business, 4(6), 1273-1274.

- Samarai, Mufid. “Sustainability of Reinforced Concrete Structures in the Gulf Region”, The 11th International Operation and Maintenance Conference in the Arabic Countries, 2013.

- Vemund Årskog, Sverre Fossdal, Odd E. Gjørv. “Life –cycle Assessment of Repair and Maintenance Systems for Concrete Structures”. International Workshop on Sustainable Development and Concrete Technology, Norway, pp 193-200.

- BSI (1984). BS 1881:Glossary of Maintenance Management Terms in Technology. HMSO, London.

- Chanter,B, swallow, P, Building Maintenance Management, Blackwell Science, 1996. London.

- McFann, G. J. (2012). History of Building Codes. Texas Professional Real Estate Inspectors Association.

- Taheri, S. (2019). A review on five key sensors for monitoring of concrete structures. Construction and Building Materials, 204, 492-509.

- Martin, J.M.M.; Munoz-Esquer, P.; Rodriguez-Lence, F.; Guemes, J.A. Fiber optic sensors for process monitoring of composite aerospace structures. In Proceedings of the Smart Structures and Materials 2002: Smart Sensor Technology and Measurement Systems, San Diego, CA, USA, 18–19 March 2002; Volume 4694, pp. 53–64.

- Toyama, N.; Noda, J.; Okabe, T. Quantitative damage detection in cross-ply laminates using Lamb wave method. Compos. Sci. Technol. 2003, 63, 1473–1479.

- Mallet, L.; Lee, B.; Staszewski,W.; Scarpa, F. Structural health monitoring using scanning laser vibrometry: II. Lamb waves for damage detection. Smart Mater. Struct. 2004, 13, 261.

- Oka, M.; Yakushiji, T.; Tsuchida, Y.; Enokizono, M. Evaluation of fatigue damage in an austenitic stainless steel (SUS304) using the eddy current probe. In Proceedings of the 2005 IEEE International Magnetics Conference (INTERMAG), Nagoya, Japan, 4–8 April 2005; pp. 427–428.

- Tsuda, H. Ultrasound and damage detection in CFRP using fiber Bragg grating sensors. Compos. Sci. Technol. 2006, 66, 676–683.

- Yashiro, S.; Takatsubo, J.; Toyama, N. An NDT technique for composite structures using visualized Lamb-wave propagation. Compos. Sci. Technol. 2007, 67, 3202–3208.

- Yu, T.Y.; Buyukozturk, O. A far-field airborne radar NDT technique for detecting debonding in GFRP–retrofitted concrete structures. NDT E Int. 2008, 41, 10–24.

- Ni, Q.Q.; Hong, J.; Xu, P.; Xu, Z.; Khvostunkov, K.; Xia, H. Damage detection of CFRP composites by electromagnetic wave nondestructive testing (EMW-NDT). Compos. Sci. Technol. 2021, 210, 108839.

- Chakraborty, J.; Stolinski, M. Signal-Level Fusion Approach for Embedded Ultrasonic Sensors in Damage Detection of Real RC Structures. Mathematics 2022, 10, 724.

- Kim, D.; Kim, R.; Min, J.; Choi, H. Initial freeze—Thaw damage detection in concrete using two-dimensional non-contact ultrasonic sensors. Constr. Build. Mater. 2023, 364, 129854.

- Elenchezhian, M.R.P.; Vadlamudi, V.; Raihan, R.; Reifsnider, K.; Reifsnider, E. Artificial intelligence in real-time diagnostics and prognostics of composite materials and its uncertainties—A review. Smart Mater. Struct. 2021, 30, 083001.

- Kaur,K.,Selway,M.,Grossmann,G.,Stumptner,M.,&Johnston,A.(2018).Towards an open-standards-based framework for achieving condition-based predictive maintenance. In Proceedings of the 8th international conference on the internet of things(pp. 16:1–16:8).NewYork,NY,USA:ACM

- Kanawaday, A., & Sane, A. (2017, November). Machine learning for predictive maintenance of industrial machines using IoT sensor data. In 2017 8th IEEE international conference on software engineering and service science (ICSESS) (pp. 87-90). IEEE.

- Chheng, C., & Likitlersuang, S. (2018). Underground excavation behaviour in Bangkok using three-dimensional finite element method. Computers and Geotechnics, 95, 68–81.

- Ayad, S., Terrissa, L. S., & Zerhouni, N. (2018, March). An IoT approach for smart maintenance. In 2018 International Conference on Advanced Systems and Electric Technologies (IC_ASET) (pp. 210-214). IEEE.

- Chen, R., Zhou, C., & Cheng, L. L. (2022). Computer-vision-guided semi-autonomous concrete crack repair for infrastructure maintenance using a robotic arm. AI in Civil Engineering, 1(1), 9.