– Engr. Shauquat Alam, Chartered Engineer President,Sovereign Infrastructure Development Company Ltd, UK

1 Abstract #

One of the KSA’s key challenges, to keep pace with the future development of the country, is to ensure that its education system is geared toward supporting the growing private sector as a means of aiding diversification and reducing reliance on state-run industries. The scenarios demonstrate that ensuring that highly qualified Saudi workers with relevant skill sets are available in an innovative economy is crucial to the country, in reducing national unemployment and the economy’s current reliance on foreign labor.

A Saudi Government initiation project – the College of Excellence (CoE), is implementing an ambitious upgrade of the Technical and Vocational Training Corporation’s (TVTC) system in the KSA through a public-private partnership with global independently run international training providers with a focus on industrial needs. This enables the youths to obtain world-class qualifications that allow them to turn their passions into successful future careers. `

The education sector in the Middle East is expected to grow exponentially on the back of a rising population, increasing private sector participation, and growing unemployment. Especially in countries like Saudi Arabia, government spending in the Education sector has been increasing and currently contributes to ~25% of the total budget. However, the share of the private sector has been gradually increasing – from 18% in 2007 to 20% in 2012. This is expected to rise to 22% in 2017. In addition, the support services management spending to upkeep the facilities to the optimum utilization is almost a SAR3million per year per facility. A component of the irrational spending on support services is largely due to the fact that most of the facilities are as old as 5+ years without being operational since their build-up.

The scenario needs processes to retain the identified educational facilities; their support services and facilities to acceptable operating standards that are often challenged by the requirement to sustain their utilities and outlook. The absence of appropriate operating strategies, maintenance methods, and adequate administrative functionalities led to keeping a backlog of maintenance and repairs of their respective built environments (now in some non-operating conditions) which may impact negatively the staff and learners’ performance and reduce their production levels.

This paper seeks to assess and evaluate the works and support services level in educational institutions by examining the effectiveness of maintenance works being carried out in connection with identifying the adoption and use of asset condition surveys and maintenance methodologies. Based on the findings a framework is proposed to assist key decision-makers to develop enduring solutions to such maintenance challenges in the educational facilities in KSA.

1.1 Introduction

We have never lived in a world of faster and more wide-reaching technological innovations. Our jobs, businesses, and how we operate as societies are being transformed by technology, and the current global pandemic is only fast-tracking digital transformation.

The Chartered Institute of Buildings (1990) defines maintenance and refurbishment as ‘work undertaken in order to keep, store, or improve the very facility and surrounds to currently acceptable Standards and to sustain the utility and value of the facility. The British Standard (BSI,1993) defines building maintenance as a combination of any actions required to retain an item or restore it to acceptable conditions.

The systems engineering field has identified maintainability and availability as important characteristics of any technological system. These parameters govern the cost and revenue components of the profit equation which directly or indirectly determines the usefulness of the system. Maintainability is a design parameter while availability is a result of implementing various systems management policies to the given technological system. The formulation and implementation of these policies are critical to achieving high system performance in terms of availability, reliability, and total life cycle cost.

In order to meet increasing performance standards, there is a growing emphasis on effectively utilizing the limited maintenance capability to carry out preventive and corrective maintenance. Planning these activities beforehand and determining the resource requirements would help the managers reduce various delays associated with maintenance activities and hence reduce the overall system downtime and life cycle costs. In order to plan and manage these maintenance activities, it is very important to understand the dynamics behind these activities and their impact on system performance. Various models have been developed and policies have been proposed to improve systems’ performance. These models have been developed with the objective of improving system availability, improving system reliability, or minimizing repair costs.

1.1.1 Justification of the Study::

A cursory look at most of the higher education institution buildings in KSA, especially those built/taken up for the TVTC system suggest that they are not well maintained. Today’s technological systems are expected to perform at very high standards throughout their operational phase. The cost associated with the unavailability of these systems is very high and especially with the HVAC or water network which can directly affect human lives. The maintenance systems play an important role in achieving higher performance targets. In order to manage maintenance activities in a more informed and rational manner, it is very important to understand the inherently complex and dynamic structure of the system. Traditionally maintenance policies are derived from the reliability characteristics of individual components or sub-systems. This research makes an attempt to understand the existing system and suggest better maintenance policies for achieving higher availability and lower system degradation. The leverage is gained from the System Dynamics framework’s ability to model complex systems and capture various feedback loops. The simulation results reveal that with the limited preventive maintenance capacity and within the given assumptions of the model, there exists an optimal preventive maintenance interval which is not the minimum. The simulation results also reflect that frequent preventive maintenance is

required at higher load factors. However, meaningful skills and knowledge need to be imparted to learners in a very conducive environment. In addition, the workplace for academic and other faculty staff must also be conducive. The study needs to evaluate current approaches to asset maintenance.

1.1.2 Aim of the Study::

The study needs to assess the constraints of Education Institution Buildings under the TVTC system with a view to evaluating their strategies, maintenance models and methods, assets sustainability, and the influence of culture in the execution of CoE programs. The existing colleges, Male and Female [@01nos each] under CoE have been taken as a pilot project for this study. The study aims to propose a theoretical strategic framework for asset management in these educational institutions.

1.1.3 Objective of the Study::

*To establish current theoretical approaches to asset maintenance management.

*To study and analyze the dynamic behavior and the causal effects of various elements of maintenance policy on the system’s economic and technical performance.

*To assess and evaluate support services and works constraints in relation to procurement strategies, maintenance methodologies & methods, effective maintenance management; and, the influence of culture.

*To develop a theoretical asset maintenance strategic framework for the TVTC system institutions.

*To formulate, analyze and compare various problems to determine the optimum level of maintenance parameters for improved system performance.

*To validate the framework (through literature surveys, interviews, and research).

2 Current Theoretical Approaches to Asset Maintenance Management #

2.1 Maintenance Strategy::

No single maintenance method and strategy can effectively provide needed remedies to both natural and artificial defects in the facility elements, like buildings, HVAC, Communication & Security & Water networks, etc.

2.2 Maintenance Methods::

The facility has been classified with various types of buildings. Hence their respective maintenance has been classified into three classes – preventive, predictive, and corrective maintenance methods. Repairs or replacement of works that are minor or major and the use of planned preventive maintenance methods have been recommended. However, in some critical areas [like electrical panel boards, motors, etc.] a stock condition survey [combination of predictive and curative – by means of infra-red recording tools] is used to assess the need for maintenance.

3 Research Methodology #

For the purpose of this study, both qualitative and quantitative approaches [mixed method research design based on pragmatism] are adopted and research questions are drawn to ensure that the study achieves its objectives. However, for the purpose of this presentation, the research used semi- structured interviews [Figure – 5, Qualitative, from the field personnel] to collect the relevant database.

3.1 Methodology and Data Collection Strategy:

The selection of a philosophical paradigm consisting of three essentials, such as Ontology, Epistemology, and Methodology has been made to be used in this study. In the whole study, both the hard and soft paradigms are used.

3.2 Research Design Criteria:

Ontology is the study of being and concerns with what is the nature of existence with the structure of reality, such as ‘meaning’ and ‘realism’.

Epistemology is the study of reality – that is, what it means to know, and that is a way of understanding and explaining how we know what we know.

And,

The methodology is the strategy, plan of action, process, or design underlying the choice and use of the particular method and linking the choice and use of methods of the desired outcomes.

3.3 Sources of Data:

For the purpose of the study, the researcher has used both primary source [literature standard data] and secondary source [field, men and equipment, actual data] collection.

3.4 Limitation of Methodology:

The study is limited to the selected TVTC system institutions (Male & Female) located in Al Aflaj, KSA, only. This area is largely underestimated to achieve the best building performance, ROi, and most importantly statutory compliance. The responsibility of Designers and Consultants to ensure the information on assets is collated from design, selection (lifecycle) and installation is critical to meet end-user expectations during operations. We have been focused on this area in practice and academically and the findings are quite common and in some instances, worst…no data exists.

4 Overview of System Dynamics Modeling Methodology #

The systems dynamic field provides a framework for modeling complex and dynamic systems. Considering the complexity and dynamics associated with the problem that has been dealt in this research,

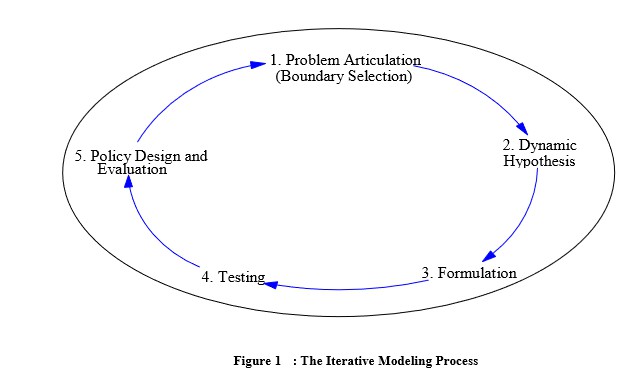

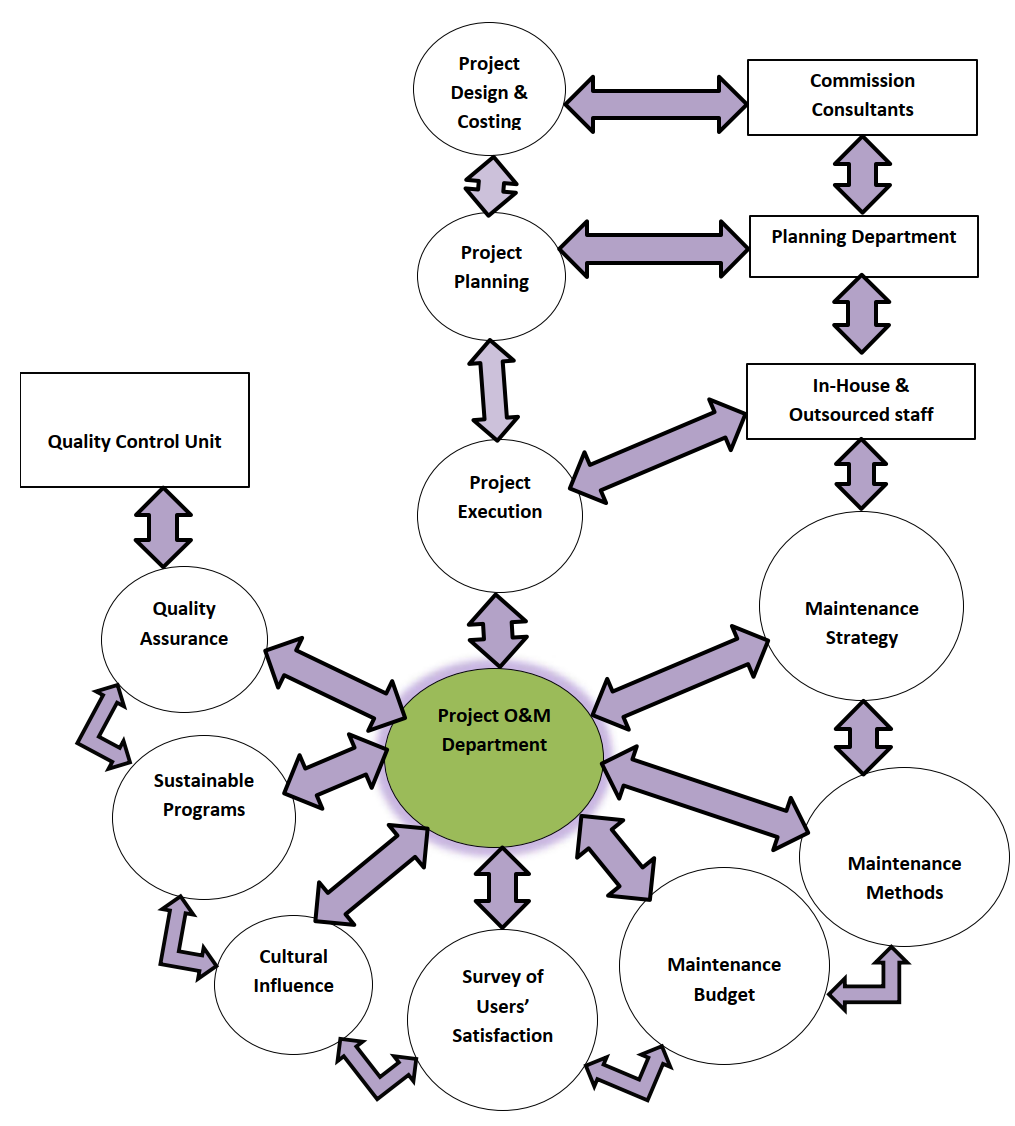

4.1. System Dynamics is considered to be an appropriate tool for modeling the system structure in this study. The iterative and continual process modeling [Figure – 1] is a part of the implementing process for formulating hypothesis testing and revision of both formal and mental models. This is an important step in the modeling process.

4.1.1 In the above-stated step the field problems were identified, defined, and clearly stated. In order to characterize the problem dynamically, the behavior of the key variables is plotted over time to illustrate how the problem arose over time and how it might evolve in the future. Also, the time horizon for the problem under study is defined so that the cause and effects that are distant in time and space are not missed.

4.1.2 An endogenous explanation has been taken into consideration while working with the dynamics of the system. Endogenous means that the dynamics are generated within the system as a result of interactions and feedback among the various maintenance elements. To manage the model and prevent the field personnel from losing focus on the various problems, the model boundary diagram or subsystem diagram was well defined. This helped the research team in defining the boundaries of our model and mapping the model based on the subsystem considerations. Next, a causal loop diagram and stock and flow structures were developed to map the causal links among the operating variables.

4.1. Formulation of Simulation Model & Testing:

4.1.3 Our inability to infer correctly the dynamics of the complex system requires us to

formulate the conceptual model that we have developed and simulate it using the software tools. Formalization helped us to recognize the vague concepts and resolve contradictions that were overseen during the conceptual phase. Each variable corresponds to a meaningful concept of the real-world scenario.

4.1.4 Testing partially involved the comparison of the model output with the real site data behavior of the system. The testing model was used for policy design and evaluation. One of the ways to design and test the policy was to change the values of some of the variables and observe if the system performance improved.

4.1.5 We found most of the time, the high-leverage policies involved changing some of the feedback structures or time delays or the stock and flow structures. The robustness of the policies and their sensitivity to uncertainties in model parameters and structures were assessed under a range of alternative scenarios.

4.1.6 The interactions of different policies were also considered: because the real systems’ parameters were insufficient (no availability) for the test; and, hence showed highly non-linear in most of the cases.

4.2. Dynamic complexity and Feedback – study conclusion::

4.2.1. Complexity is defined in terms of the number of components in a system or the number of combinations one must consider in making a decision. This is called combinatorial complexity. Dynamic complexity can arise even in simple systems with low combinatorial complexity. Dynamic complexity results from the combination of interactions among system elements over time. Even systems with low combinatorial complexity can exhibit a high level of dynamic complexity. Complex behavior is observed in systems that are dynamic, tightly coupled, governed by feedback, non-linear, counterintuitive, and policy resistant.

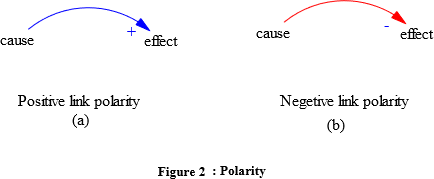

4.2.2. In complex systems nothing is stand alone and everything is connected to everything else. They interact with each other through In fact, the most complex behaviors usually arise from the interactions among the components of the system, not from the complexity of the component themselves. Feedback processes along with the stock and flow structures, time delays, and nonlinearities determine the dynamics of the system. Causal loop diagrams [Figure – 2] were used for representing the feedback structure of the systems.

4.2.3. Feedback is one of the core concepts of system It captures the interactions among the elements. A causal loop diagram consists of two or more causal links that connect the various elements in the model. Each link is assigned a polarity, as shown in figure-2, to indicate the direction of change of the affected element with respect to the causing element. A positive link means that if the cause increases the effect increases above what it would have been; and, if the cause decreases the effect decreases below what it would otherwise have been.

4.2.4. A negative link means that if the cause increases the effect decreases above what it would have been; and, if the cause decreases the effect increases below what it would otherwise have been. It is important to note that link polarities describe the structure of the system and not the behavior of the variable parameters under test.

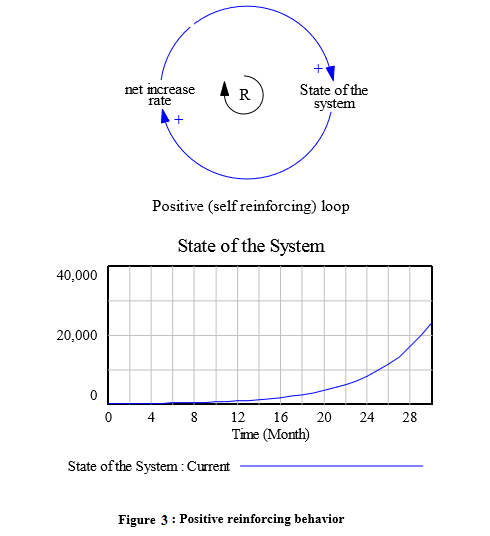

4.2.5. Three fundamental modes of behavior and three derived modes of behavior were taken into consideration while conducting this study. Each of these modes was generated from a particular type of system structure, which included a positive loop, a negative loop, and balancing loops with delays. An example, as shown in Figure – 3, is the exponential growth resulting from a positive feedback loop. The loop shows the general structure of a positive feedback loop. With the increase in the state of the system net increase rate increased, which further increased the state of the system. This caused the state of the system to grow exponentially as shown in the graph.

4.2.6. Simultaneously, goal-seeking behavior; oscillations that are observed frequently in dynamic systems; ‘S-shaped growth with overshoot and collapse; and, other modes of behaviors were also studied.

4.2.7. In some systems especially in HVAC and Chiller networks, it is extremely important to avoid failure during the operation as it can be dangerous or disastrous. Also given the cost associated with these systems and their importance for organizational performance, the availability and degradation of these systems over their operational phase are extremely important.

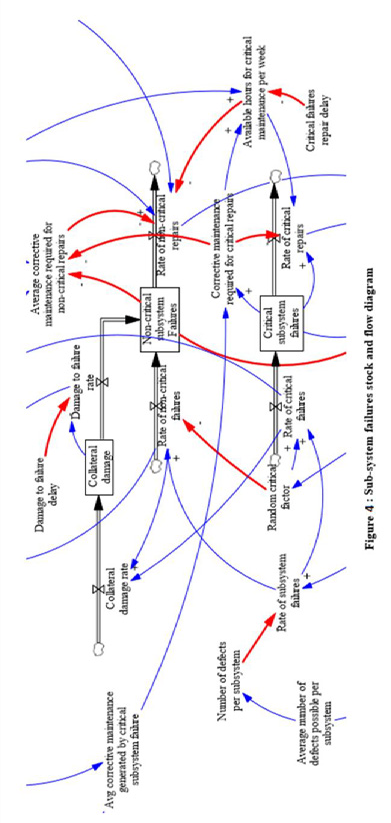

4.2.8. The economic impact of machine availability, reliability, as well as corrective maintenance costs, are demanding considerable improvement in maintenance techniques and operations to monitor machine degradation and defect faults in the production system. Hence, in order to improve system availability and reliability, various maintenance policies have to be proposed and tailored made to site assumptions and considerations. A typical sub-system failure is shown in Figure – 4.

5 Optimal Stopping models #

Another unified maintenance modeling framework with six classifying factors is developed for formulation and analysis of a wide range of maintenance systems, under which many existing models in literature were formulated as optimal stopping models. A systematic optimization methodology was developed based on optimal stopping, semi-martingale, and λ- maximization techniques A concrete model was presented and solved as an example to illustrate the proposed modeling and optimizing methodology.

5.1. Maintenance Modeling Framework:

5.1.1. The diversity and complexity of maintenance problems from various practical situations have led to numerous concrete models and policies. While it is not possible to come up with a generic model that can describe all interesting situations and scenarios, it is feasible to generalize and reorganize the conceptual models under a unified maintenance modeling framework based on the essence of these problems.

5.1.2. We considered a maintenance system that consists of stochastically identical and independent units which are put into use sequentially in time. The unified maintenance modeling framework proposed for such a system includes six factors:

(i) Maintenance Horizon: it describes the time interval on which all the maintenance activities take place.

(ii) System Deterioration Dynamics: it describes how the system becomes more and more prone to failure.

(iii) Maintenance Actions: it describes various preventive measures and ways to rectify system failures.

(iv) Cost Structures: it describes the costs that are related to maintenance actions and the loss due to system failure.

(v) Information Level: it describes information on system conditions that is available for decision- making.

(vi) Objective Criterion: it describes the objective of maintenance management, which could be the minimization of cost or maximization of benefits.

5.2 In this study, we have proposed a unified maintenance modeling and optimization methodology for single-unit repairable systems, with which policy comparison and optimally verification are carried out in a systematic manner and a natural structure among many models is established.

5.2.1. The whole procedure of analyzing a maintenance policy problem can be described as follows –

- Specify the six factors under the modeling framework.

- Find the optimal policy in admitted stopping time class for each model. And,

- Evaluate policies based on the related model comparisons.

5.2.2. A general maintenance modeling framework with six classifying factors was developed for formulation and analysis of a wide range of maintenance systems, under which many existing models in literature could be nicely incorporated and reformulated as optimal stopping modes.

5.2.3. A systematic optimization methodology was developed based on optimal stopping, semi- martingale, and ƛ-maximization techniques. A concrete model was presented and solved as an example to illustrate the proposed methodology, where the numerical analysis lead to some additional insights which are beyond the scope of this research.

6 Conclusion & Facility Users Satisfaction #

6.1 Satisfaction surveys:

Any fault or defect discovered during the research was recorded and reported for immediate action [corrections of the defects]

6.2 Quality Control and Risk Assessment of Maintenance projects:

The quality of facility buildings was determined by desk top process design, materials’ quality of ongoing O&M process, and instant desk communication between facility users and ground O&M personnel. Quality management and Risk assessment cum mitigation were aimed to increase facility users’ and customers’ satisfaction.

6.3 Sustainability of the Built Environment:

Project performance has been considered in terms of cost, time, and quality that asserts sustainability development that has been divided into three types – Build for Durability (Social); Make the Environment Safe (Environment), and Use of Materials from Sustainable Resources (Economic). Sustainable development is a development that meets the needs of the present without compromising the ability of future generations to meet their own needs. However, in the future study, we may also research a different scenario placing local strategies in environmental sustainability, material resourcing, waste disposal, and energy management policies in an attempt to set up a framework to achieve a sustainability operation.

6.4 Use of Maintenance Control Computer-based program::

The replacement of the use of existing manual maintenance control toolkit, such as maintenance schedule, maintenance program, job specification, and facility register by computerized

maintenance software shall make the maintenance project planning, execution, monitoring and evaluation efficient and effective and reduce maintenance costs.

6.5 The study emphasized the great importance to put theoretical investigation into the practice. The proposed modeling framework of Dynamic Maintenance and Optimization procedures in fact is very convenient for the design and implementation of the O&M procedures vied a computer- based system.

6.6 From a user’s perspective, the model construction process makes it very easy to select a model that is most appropriate and tailored made to one’s own application needs. From a designer’s point of view, the common optimization procedures enable efficient implementation of the system. The availability of such a system further closes the gap between theoretical results and practical field needs.

6.7 The most promising and challenging topic in the field of maintenance is emerging Condition Based Maintenance [CBM], also known as Sensor Based Maintenance [SBM], which is both technology-intense and information-intense. The optimal stopping approach represents a very appropriate tool due to its strength in representing, processing, and utilizing information.

6.8 While some works have applied optimal stopping in CBM, a systematic investigation on this topic is still lacking and need wide-based research and investigations. It is a strong belief, after this research, that serious studies in CBM with Optimal Stopping methodology could contribute significantly to the pursuit of maintenance excellence.

6.9 As an ongoing process, we have developed the following semi-structured element-wise interview as an ideal approach for a similar study [Figure – 5].

Figure – 2 : Culled from the semi structured interviews – 2015

7.0. List of References #

- Beichelt, F. (1993), “A unifying treatment of replacement policies with minimal repair,” Naval Research Logistics 40, 51-57.

- Bloch-Mercier, S. (2002), “A preventive maintenance policy with sequential checking procedure for a markov deteriorating system,” European Journal of Operational Research 147, 548-576.

- Block, H.W., Borges, W.S. and Savits, T.H. (1988), “A general age replacement model with minimal repair,” Naval Research Logistics 35, 365–372.

- Block, H.W., Langberg, N.A. and Savits, T.H. (1990), “Maintenance comparisons: block policies,” Journal of Applied Probability 27, 649-657.

- Bahrami K, Prince J, Mathew J, “The constant interval replacement model for preventive maintenance”, International journal of quality and reliability management, 2000, vol 17.

- Aven, T. (1983), “Optimal replacement under a minimal repair strategy – a general failurev model,” Advances Applied Probability 15, 198-211.

- Aven, T. and Bergman, B. (1986), “Optimal replacement times–a general set-up,” Journal of Applied Probability 23, 432-442.

- Aven, T. (1996), “Condition-based replacement policies – a counting process approach,”

- Reliability Engineering and System Safety 51, 275-281.

- Aven, T. and Jensen, U. (2000), “A general minimal repair model,” Journal of Applied Probability 37, 187-197.

- Barlow, R.E., Hunter, L.C. and Proschan, F. (1963), “Optimum checking procedures,” Journal of the Society for Industrial and Applied Mathematics 4, 1078-1095.

- Davies A., “Management guide to condition monitoring in manufacturing”,The institute of Production Engineers, 1990, London.

- Kim C, Djamaludin I, Murthy D, “Warranty and discrete preventive maintenance”,

- Reliability Engineering and System Safety, 2004; 84; 301-309 Lam C., Yeh R., “Optimal maintenance-policies for deteriorating systems under various maintenance strategies”,

- Dagpunar, J.S., Jack, N., “Preventive maintenance strategy for equipment under warranty”, Microelectronics and Reliability, 1994; 34 (6); 1089–1093.

- Block, H.W., Langberg, N.A., Savits, T.H., “Repair replacement policies”,Journal of Applied Probability, 1993; 30 (1); 194–206.

- The Building Commissioning Guide – GSA

- Lincoln College, UK (H&SE Policy) – Mr. Ian Dobson, Executive Director for Facilities and Estates, KSA.

- Conditioning Survey sittings – Mr. Anders Berndtsson,L&TS Resources Manager, Saab Saudi LLC, Riyadh.