Luís Picado-Santos*, César Abreu**

- CERIS, Instituto Superior Tecnico, Universidade de Lisboa, Lisbon, Portugal. luispicadosantos@tecnico.ulisboa.pt

- ACIV, Department of Civil Engineering, University of Coimbra, Coimbra, Portugal. cfcabreu@uc.pt

Abstract #

One of the main difficulties for an infrastructure manager is to achieve the most efficient way to apply his financial resources to maintain the network level of service. The use of a Pavement Management System (PMS) aid to decide about the set of interventions to be chronological made in the infrastructure to cope with the needs of level of service at the lower cost. This paper addresses the development and, in some extent, the implementation of PMS for the Portuguese international airport network and for national and municipal road networks. The networks were characterized for pavement bearing capacity, and using surface characteristics surveys and visual inspection campaigns. The PMS systems include an aid-decision tool using a deterministic performance model for the pavements. The aid-decision tool computes the best preventive strategy for the network maintenance. This decision-making process takes into account the current situation, the traffic forecasts, quality levels established by the manager and economic scenarios (in some extent). The entire system could be controlled through a web-based interface, where the manager can access to all information contained in the database and trigger the intervention plan and costs according to the analysed scenario. The paper describes different stages of development and adaptation of the system to meet the needs expressed by the infrastructure manager. It is also given a flavour of what it will be expect to develop within the next 3 to 5 years to come.

Keywords: Pavement Management System; aid-decision tool; web-based interface

1 Introduction #

Due to the demanding requirements of performance and safety, transport infrastructure pavements must be ensured throughout its service life. These requirements, along with the increase of traffic, have triggered maintenance and repair needs. These coupled with budget constraints, led managers to address the performance and rehabilitation of the pavements in a more effective way.

Even for airport pavement management scope, the present limitations pop out when the regular “reaction to distress” approach was unable to be funded due to budget constrains [1]. Road and Airport management administrations were forced to deal with their infrastructures in a much more preventive than reactive approach [2].

In this context, developing a tailored PMS is the solution that not only responds to the necessary optimization of resources but also minimizes the interventions that interfere with the normal infrastructure operations [3].

2 PMS development #

2.1 General structure #

According to our experience, the developed systems for road or airport pavements were self-contained systems to be operated in one workstation [4].

In continuation, the system description taken as example was developed for an international network of airports as a web-based system [5], in order to allow remote access to all information for the pavement maintenance groups in the different airports. This was the same with the present systems for a national road network with different hierarchies but not for a local road network just for dimension reasons or for a motorways concession network for similar reasons.

The systems are generally developed over a geographical information system (GIS) layout that allows representation and use of all data, historical or the one resulting of the planned interventions.

In the case of airport pavement management system (APMS), recently developed, the structure was divided into five modules. The first module, “Administration”, allows the definition of how the system will be used, by whom and for which infrastructure and system modules. It also allows that new features could be added at any time.

In the second module, “Import Data”, users can deal with all type of necessary data related to the infrastructure layout and condition. This type of database contains information about the characterization of materials and pavements, traffic characteristics and volume and the expected demand trends, all included in a timeline.

The third module, “Query”, allows the use of the results for all condition states surveyed. This information is presented in numeric form as well as in graphic form and is always represented in the network map, allowing the user to easily obtain information related to a certain section.

In the fourth and fifth modules, “Management” and “Evaluation” respectively, the user can manage the parameters to consider in the different scenarios to be tested by the evaluation model. For each of the scenarios, which can differ in the traffic prediction, pavement condition level to achieve and the macroeconomic constrains, the aid-decision model will calculate the optimal resource allocation on those conditions. The results of all studied scenarios are described in a report.

The manager, in order to decide about the plan for the pavement interventions with a time-span usually till the next five years, will use the support of the aforementioned report produced in module five and all the additional constrains that could not be included in the studied scenarios, which are related to unexpected policy changes within the managing structure.

2.2 Pavement condition survey #

For the development of the system, an extensive and consistent along the time job of characterization of type of all infrastructures should be carried out to obtain the necessary knowledge concerning the pavements behaviour and its condition evolving. In the case of the APMS used as support of this description, the campaign took three years and it consisted of an exhaustive analysis of all the available documentation about construction and rehabilitation parameters, as well as numerous field surveys [6] (Picado-Santos and Abreu, 2012).

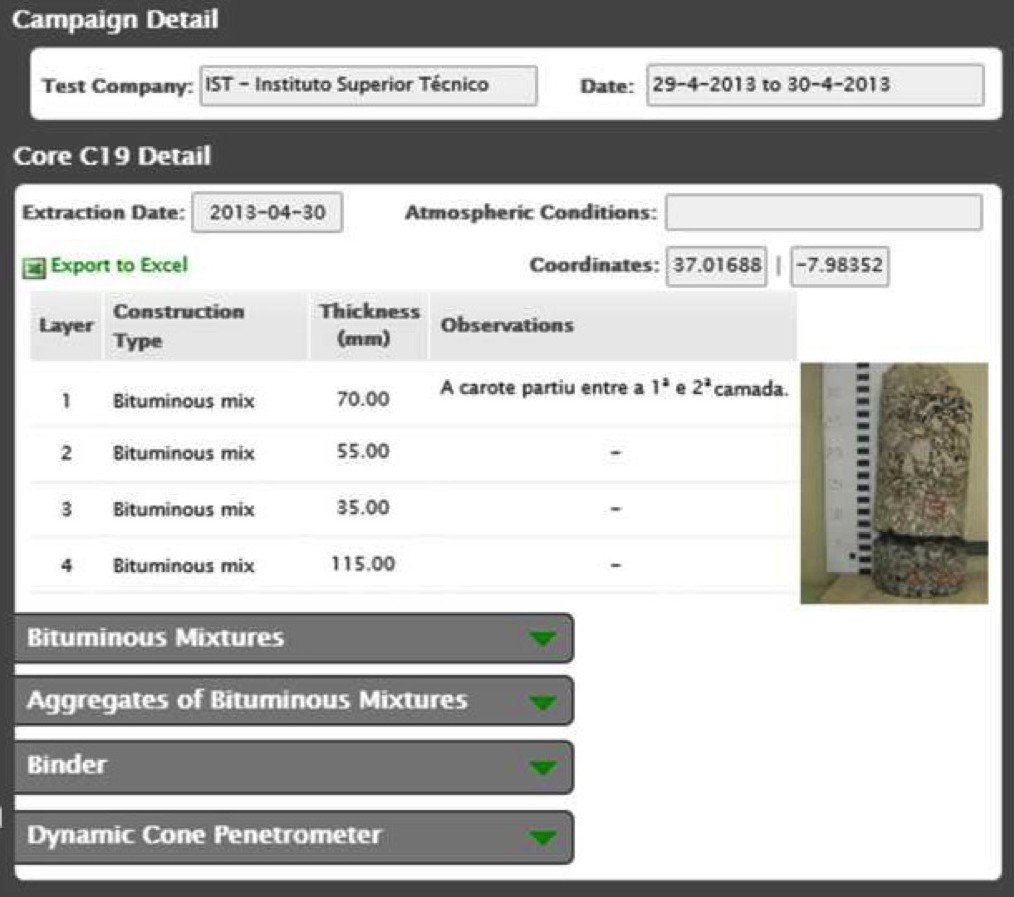

For the structural characterization of the airport pavements, a super heavy falling weight deflectometer survey was done together with foundation and pavement prospection jobs and laboratory tests, allowing the definition of the pavement’s mechanical characteristics (Figure 1).

Figure 1: Example of the system screen layout for the registration of the obtained core characterization in laboratory

Some pavement surface characteristics, in operational areas, were obtained by doing a laser profiler survey that delivered IRI (International Roughness Index), ETD Texture (Estimated Texture Depth, equivalent to MTD/sand-patch method) and Straightedge [7].

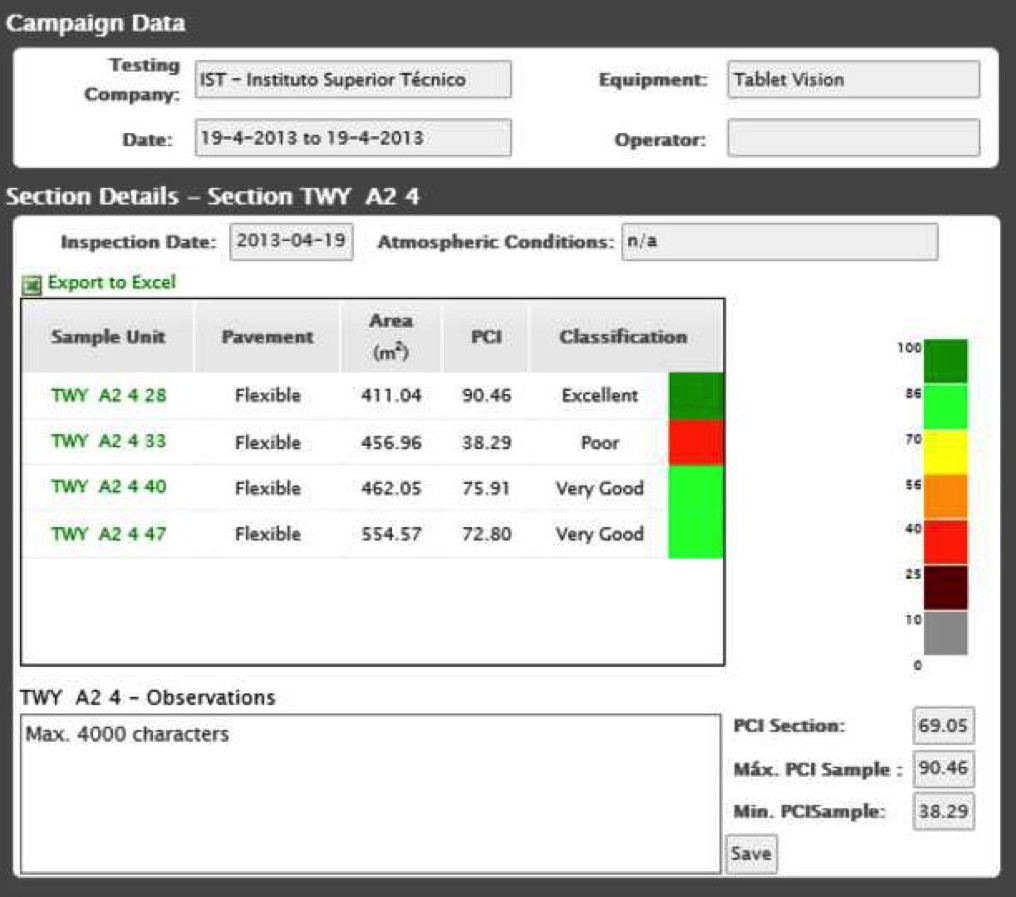

A specific computerized tool was developed to assist in the visual inspection campaigns. Through its use, and complying with the ASTM D5340-14 Standard [8], all obtained data was georeferenced and ready to be loaded to the system database (Figure 2).

Skid resistance surveys and images that were captured by videography for all the infrastructures were also added to the database in order to deal with live safety issues and allow that some particularities could be checked directly in the system.

2.3 Aid-decision framework #

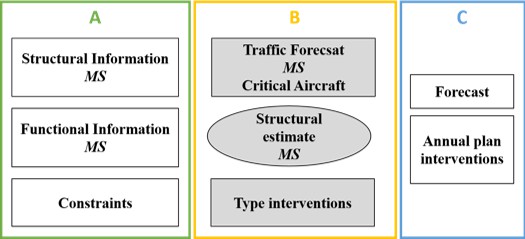

The APMS’ aid-decision framework uses a deterministic performance model to set the evolving of the pavement condition [9,10]. In terms of structure, the aid-decision framework is divided in three units – A, B and C – as shown in Figure 3.

In unit A, the information of the database, both historical and collected throughout the years of the characterization surveys, is then considered for each of the “Management Sections” (MS) considered as the managerial unit for each infrastructure. All MS here considered originate in the subdivision of each branch of an airport (runway, taxiway and apron) in order to guarantee homogeneity for structural and functional conditions, and traffic.

The creation of these MS allows the model to provide a more detailed solution, which helps the airport manager to adjust the interventions to the needs [11]. Unit A also includes all constraints. These can be divided in quality restrictions [12], measured in years of residual life, financial restrictions as the infrastructure update rate and operational restrictions [13]. The manager sets the planning period, necessary for the analysis, in this unit.

Figure 2: Example of the system screen layout for the registration of visual inspection campaigns

Figure 3: Structure of the aid-decision framework

The main quality restrictions are the residual life at the end of the planning period and at the end of each year. All the optimization process is carried out to meet the quality requirements represented by the chosen values that will be considered in the objective function. The minimum residual life that activates an intervention priority (when this value is reached the MS in question is intervened in the next period) and the minimum admissible residual life at the end of the planning period are regarded as quality constraints as well.

The update rate and the penalty for not respecting the quality restrictions are the only budget related constraints considered. The latter parameter represents the managerial costs of not observing the quality restrictions, which can represent some costly unplanned/emergency interventions for the future.

In operational terms, the constraints observed are the number of days an intervention can take place (excluding peak periods and/or adverse weather conditions) and the number of sections that can undergo an intervention in a specific year (this parameter intends to minimize the impossibility of intervention for operational reasons). Table 1 shows the list of all constraints.

In unit B (Figure 3), the prediction model for the pavement state is activated. To set this model it was used a neural network approach, calibrated for different critical type of vehicle (airplane for APMS) and different type of interventions over the pavement. Each APMS’ MS is then subjected to traffic prediction according to the critical airplane for the specific airport infrastructure and the known growth rate for the traffic is assigned to each one. A catalogue of possible interventions is also available, characterized by their physical (type of materials and thickness) and structural characteristics, as well as [4] the productivity (m2/h) and unitary cost (€/m2) of each.

| Constraint | Type of Constraint | Unit |

| Planning Period | – | Year |

| Intended Quality Objective for the section at the end of the analysis period | Quality | Year |

| Intended Quality Objective for the section in each year of the analysis period | Quality | Year |

| Penalty to restore the intended residual life in terms of cost in each section | Monetary | % |

| Minimum residual life (for activation of intervention priority) | Quality | Year |

| Update rate | Monetary | % |

| Minimum residual life at the end of the analysis period | Quality | Year |

| Maximum number of intervention days in a given year | Operational | – |

| Maximum number of sections with interventions in the same year | Operational | Day |

Table 1: List of constrains used for the described APMS

In selecting the type of interventions, aspects as the location of the infrastructure [14], Portuguese technological practice [15,16] and practical experience for each infrastructure were taken into account.

The unit C (Figure 3) is where the different future possible scenarios are treated, taking into account constraints and information from the previous units. The best strategy is the one that best fits the material and financial resources available, in general the one that minimizes the total cost of the investment, fulfilling the quality requirements established. The annual plan, year by year of the planning period, includes the interventions described by type and MS, the pavement state and the budget needed.

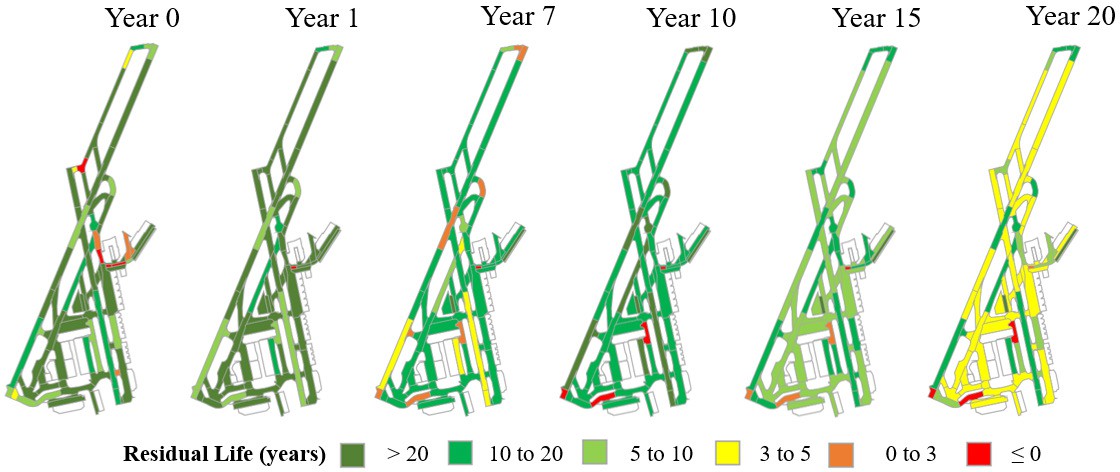

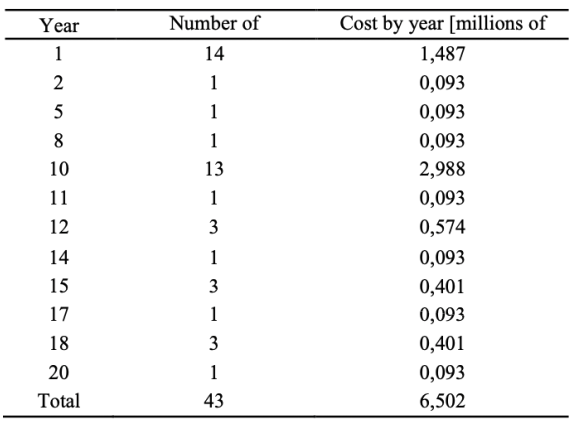

Just as illustration, if an analysis period of 20 years is taken as well as the type of constrains described, in Figure 4 is possible to visualize the pavement condition evolving, actually represented by the pavement residual life. In Table 2 is possible to see the investment plan proposed by the model, which is comprised of forty- three interventions costing a total of 6,502 million euros. At the end of the planning period, the average residual life of the 78 MS considered was 6,6 years.

Figure 4: Example of the pavement condition evolving for an airport infrastructure

3 Conclusions #

It can be stated that the developed APMS, after the implementation phase already performed by the manager, provides a deep knowledge about the infrastructures as the database, including present and future (resulting of the implementation of the best strategy possible) conditions, allows an easy and fast assessment of the pavements’ condition.

With the implemented aid-decision tool, the manager can, besides the security and conditions checks (a daily basis concern for airports), evaluate the pavement conditions when subject to a specific traffic and investment scenario. This evolution measured in terms of the pavement residual life allows the adjustment of the investment plan at any time. In this way, the non-predicted alterations at the beginning of the planning period (for instances changes in traffic volume and typology or the infrastructure layout) can be easily added originating a new investment plan, more suitable to the situation. For each tested scenario a detailed report is elaborated with a number of proposed intervention plans, their costs and the influence of the chosen plan in the quality parameter of the area to intervene.

Table 2: Example of an investment plan proposed by APMS for the illustration related with Figure 4

Nevertheless, and specially for this APMS, some drawbacks should be stated as the fact that the pavement performance model showed to be quite sensitive to traffic estimates and its network distribution, generating significant additional costs when these estimates are overlooked for each MS. This could lead to a loop decision framework by the system, for example allocating the same intervention several times during the planning period due to excess of predicted traffic for an initial pavement structure in poor condition. Other aspect concerns the available time (maximum number of intervention days in a given year) for executing the planned interventions in a specific year. If it was not enough, the aid-decision tool moves that intervention to the following year and so on, generating an over cost due to the impossibility of carrying out the intervention at the right time (year).

The generally described APMS was a tailor-made system for the manager, developed according to his needs and requirements. The same happened with the different road network managers for whom similar systems were developed. This fact allows much more effective decisions about network maintenance, resulting in a more efficient use of human, material and financial resources.

Finally, according to our experience, the managers are pretty much dependent of the financial strategies of the top management of their organizations. In this sense, aspects as financial risks to support investment and consideration of uncertainty for the economic evolvement of a country, a region or even the world, should be introduced in the PMS analysis, together with other more technological type of risks and uncertainties. Planning with flexibility to adjust to different situations is the key issue for the next generationofPMS.

References #

- FAA (Federal Aviation Administration). “AC 150/5380-7B – Airport Pavement Management Program (PMP)”. Advisory Circular 150/5380-7B, (www.faa.gov/airports). (2014).

- White, G. “Challenges for Managing Australian Airport Pavements”. Proc., World Conference on Pavement and Asset Management, WCPAM2017, Baveno-Milan, Italy, PSR 12. (2017).

- Wu, Z., Flintsch, G., Ferreira, A., and Picado-Santos, L. “Framework for Multi-Objective Optimization of Physical Highway Assets Investments”. J. of Transportation Engineering, 10.1061/(ASCE)TE.1943-5436.0000458. 138 (12), 1411- 1421. (2012).

- Picado-Santos, L., Ferreira, A., Antunes, A., Carvalheira, C., Santos, B., Bicho, H., Quadrado, I, Silvestre, S. “The Pavement Management System for Lisbon”. ICE-Municipal Engineer (Journal of Institution of Civil Engineers), 157 (ME3), 157-166. DOI:10.1680/muen.2004.157.3.157. (2004).

- Mooney M. A., Khanna V., Yuan J., Parsons T., and Miller G. A. “Web-Based Pavement Infrastructure Management System.” J. of Infrastructure Systems, 10.1061/(ASCE)1076-0342(2005)11:4(241), 11(4), 241–249. (2005).

- Picado-Santos, L., and Abreu, C. “Aeroporto João Paulo II – Caracterização estrutural e caracterização da superfície do pavimento da pista (12-30) [Airport João Paulo II – Structural and surface caracterization of the runway (12-30) pavement].”, Technical report, Instituto Superior Técnico – Universidade de Lisboa, Lisboa – Portugal (in Portuguese). (2012).

- Backer, P., Debroux, R., Freneat, E., Kannemeyer, L., Linder, T., Otomo, O., Russel, K., Picado-Santos, L., Tazaki, T., Thomassen, T., and Zarghampour, H. “Integration of Performance Indicators”. PIARC TC 4.1.2, R2008R06, Paris. (2008).

- ASTM. “Standard Test Method for Airport Pavement Condition Index Surveys.” D5340, ASTM, Philadelphia, PA. (2014).

- Ferreira, A., Picado-Santos, L., and Antunes, A. “A Segment Linked Optimization Model for Deterministic Pavement Management Systems”. The International Journal of Pavement Engineering, 3 (2), 95-105. DOI:10.1080/10298430290030603. (2002b).

- Carvalho, A., and Picado-Santos, L. “Maintenance of airport pavements: the use of visual inspection and IRI in the definition of degradation trends”. International Journal of Pavement Engineering. DOI: 10.1080/10298436.2017.1309189. (2017).

- Ferreira, A., Picado-Santos, L., Wu, Z., and Flintsch, G. “Selection of pavement performance models for use in the Portuguese PMS”. International Journal of Pavement Engineering, 12 (1), 87–97. DOI:10.1080/10298436.2010.506538. (2011).

- Ferreira, A., Antunes, A., and Picado-Santos, L. “Probabilistic segment-linked pavement management optimization model”. J. of Transportation Engineering, 10.1061/(ASCE)0733-947X(2002)128:6(568). 128 (6), 568-577. (2002a).

- Zou, B., and Madanat, S. “Incorporating Delay Effects into Airport Runway Pavement Management Systems.” J. of Infrastructure Systems, 10.1061/(ASCE)IS.1943-555X.0000086, 18(3), 183–193. (2012).

- Picado-Santos, L. “Design Temperature on Flexible Pavements: Methodology for Calculation”. International Journal of Road Materials and Pavement Design, 1 (3), 355-371. (2000).

- Capitão, S., and Picado-Santos, L. “Applications, Properties and Design of High Modulus Bituminous Mixtures (HMBM)”. International Journal of Road Materials and Pavement Design, 7 (1), 103-117. 10.108014680629. 2006.9690029. (2006).

- Picado-Santos, L., Baptista, A., Capitão, S. “Assessment of the Use of Hot Mix Recycled Asphalt Concrete in Plant”. J. of Transportation Engineering, 10.1061/(ASCE)TE.1943-5436.0000190, 136 (12), 1159-1164. (2010).