Rami Alsodi 1, Mohamed G. Arab2, Mufid Samarai1

1 Sharjah Research Academy, Government of Sharjah

P.O. Box 2580, Sharjah, United Arab Emirates; ramy@sra.ae; mufid.samarai@sra.ae

2 Department of Civil and Environmental Engineering, College of Engineering, University of Sharjah P. O. Box

27272 Sharjah, Sharjah, UAE marab@sharjah.ac.ae.

Abstract #

Bio-mediated techniques such as Microbial induced carbonate precipitation (MICP) and Enzyme induced carbonate precipitation (EICP) have shown great potential as sustainable and environmentally friendly binder alternatives to conventional cementing binders. These techniques can modify and enhance the mechanical properties such as strength, stiffness, and permeability of construction materials.

MICP and EICP rely on the precipitation of calcium carbonate as a basis for improving the mechanical properties of soils. More recently, these techniques have also shown great potential for concrete crack healing. These methods have great potential to reduce production and operation costs and the environmental impact of concrete.

This review paper will explore the application of both MICP and EICP in mortar crack healing and the potential of using these methods as a maintenance tool for construction materials. These methods can be utilized in overall asset management, especially in the middle east region where challenges such as the hot climate may affect the overall concrete quality.

Keywords –crack healing, maintenance, bio-cementation, carbonate precipitation

1 Introduction #

Concrete is a very valuable asset since it is widely used in modern structures. Although concrete is considered a relatively inexpensive material, it is necessary to preserve the concrete structure to last longer. Ordinary Portland cement (OPC) is a major source of carbon dioxide emissions worldwide and is considered a serious source of global warming. Moreover, preserving the concrete structures has several social and economic benefits for the community since it will preserve these structures for an extended period and improve these structures’ serviceability.

Recently, extensive research has been undertaken to enhance the durability of concrete mixes as well as introduce maintenance methods that improve the concrete service life. One of the most contributing factors to the deterioration of concrete elements is cracking. Especially, in a hot climate and arid environments as in the Middle East region where concrete deterioration occurs at a faster rate. Temperature increases result in many cracking-related issues such as shrinkage cracking and drying shrinkage cracking [1]. If this issue is tackled properly, it will significantly enhance the durability of the concrete structure and increase its service life.

Cracking makes concrete prone to harmful chemical attacks that lead to the corrosion of the reinforcing steel as well as other chemically induced durability problems. One way of solving the issue is to produce concrete mixes that are not susceptible to cracking using admixture such as micro silica [2].

Another alternative is to seal the cracks after it is already formed and propagated. Several strategies have been already implemented to seal the cracks in concrete, such as using epoxy-based materials, acrylic resins, and silicon-based polymers [3-5]. However, these methods tend to be more expensive and not environmentally friendly.

Therefore, sustainable methods alternative has been proposed recently for the application of concrete healing. Enzyme Induced Carbonate Precipitation (EICP) and Microbial Induced Carbonate Precipitation (MICP) are proposed to heal concrete cracks via the precipitation of carbonate in these cracks.

2 MICP and EICP Treatment Mechanism #

Both methods rely mainly on calcium carbonate precipitation to seal the concrete crack. In general, the process of urease- aided carbonate mineralization (irrespective of the enzyme source) is derived by the urease catalyzing the hydrolysis of urea. This reaction resulted in producing carbon dioxide (CO2) and ammonia (NH3) transferring into ammonium (NH4+) in an

aqueous environment and thereby increasing the pH of the solution. The increase in the pH, in the presence of dissolved Ca2+, creates favorable conditions for the ions to merge forming calcium carbonate precipitates. The overall process is summarized in Figure 1.

As shown, the overall reaction takes place by the supply of carbonate ions resulting from the hydrolysis of urea and of alkalinity generated by the reaction. When calcium carbonate precipitates within the concrete crack, it works on sealing it and prevents further harmful chemical leakage in these openings. The difference between MICP and EICP lies in the urease enzyme source. MICP process the urea hydrolysis utilizing bacteria (sporosarcina pasteurii) as a source of urease enzyme [7]. On the other hand, EICP contains urease from agricultural sources such as the Jack bean. [8-9].

Figure 1 Summary of the hydrolysis and precipitation reaction [6].

3 MICP and EICP as Tools for Concrete Crack Healing #

There are many methods that can be implemented to evaluate the enhancement of mediated healing of concrete. It could be evaluated in terms of crack sealing that is measured through permeability testing such as water absorption and chlorine rapid migration test. Moreover, the concrete healing effectiveness could be measured by evaluating the regained strength by performing unconfined compressive strength or flexural strength testing. This section will discuss each of these aspects from the literature.

3.1 Permeability reduction #

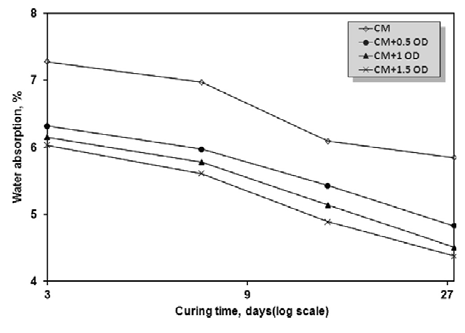

A major cause of durability reduction in concrete when it gets cracked is the seepage of harmful liquids in the concrete. When fluids seep inside the concrete it causes corrosion of the reinforcing steel, thereby reducing its strength and its expected age as well. Sealing these cracks is very useful to block this seepage. Abo-El-Enein et al. [10] performed a water absorption test on concrete samples cured at 3, 7, 14, and 28 days. The study compared samples treated at bacterial cell concentrations of optical densities of 0, 0.5 1, and 1.5. The bacteria culture of S. pasteurii was thoroughly mixed with sand and cement according to the corresponding optical density. After 24 hours the samples were demolded and cured in a solution of 20 g/L urea and 25 mM of calcium chloride for the specified interval.

As shown in Figure 2, the higher the optical density of the bacterial cell concentration the more reduction in water absorption is achieved. Reduced water absorption will highly enhance the durability of the treated concrete element. Manzur et al. [11] studied the effect of MICP treatment on concrete water sorptivity using ASTM C1585-13 standard test. A reduction of 37% was observed when comparing biotreated concrete against control samples.

Figure 2 Comparison between the water absorption % between concrete samples treated at different bacterial cell optical densities [9].

Kulkarni et at. [12] tested the water permeability of biotreated concrete using the constant head method as per IS-2720 (Part 17) 1986. After intentionally generating the artificial cracks using a jaw clamp, the samples were ready for repair using MICP. The concrete cracked samples were soaked in bacterium solution and urea-CaCl2 for treatment. The test results show up to 80% reduction in the water permeability of the cracked concrete after treatment.

3.2 Strength regains #

MICP and EICP produce calcium carbonate within the concrete cracks. Calcium carbonate is a cementing material that will work on binding cracks again. This binder will help in regaining part of the flexural or compressive strength of the damaged concrete. Abo-El-Enein et al. [10] found that treating the cracks with MICP leads to an increase in compressive strength from 200 to 280 kg/cm2. Moreover, Manzur et al. [11] observed an increase of up to 15% in compressive strength compared to control specimens, when treating the concrete with MICP. Dakhane et al. [13] show that treating pre-cracked concrete beams with EICP method leads to an approximately 33% increase in flexural strength and double the fracture toughness. The method of inducing the crack and healing process for Dakhne et al. [13] is shown in Figure 3. The notch above the crack was filled with EICP solution in order to permeate inside the generated crack to induce the healing process.

Figure 3 Experiment schematic adopted by [12]

Kulkarni et al. [12] performed a split tensile strength test according to IS 5816-1999. The test was performed on intact and undamaged samples and it produced a strength of around 3600 kPa. After inducing the cracks on the samples, the untreated samples fail immediately after applying a negligible load. The cracked samples were then healed by soaking into a bacterium solution for 2 hours, and then they have soaked again in a Urea-CaCl2 solution. These MICP-treated samples have shown regain in strength in the range of 29.85 to 380.5 kPa. This is almost 10% of the original strength before cracking.

4 Cost Implications of utilizing Self-Healing Concrete #

Self-healing concrete can be a great maintenance tool since the main purpose of utilizing it is to seal the load-induced cracking through the precipitation of calcium carbonate. Concrete has a low tensile strength which makes it susceptible to cracking during its service life [14]. Cracking is one of the main factors causing the degradation of concrete durability. Timely repair of concrete cracks may contribute to extending the service life of concrete structures [15].

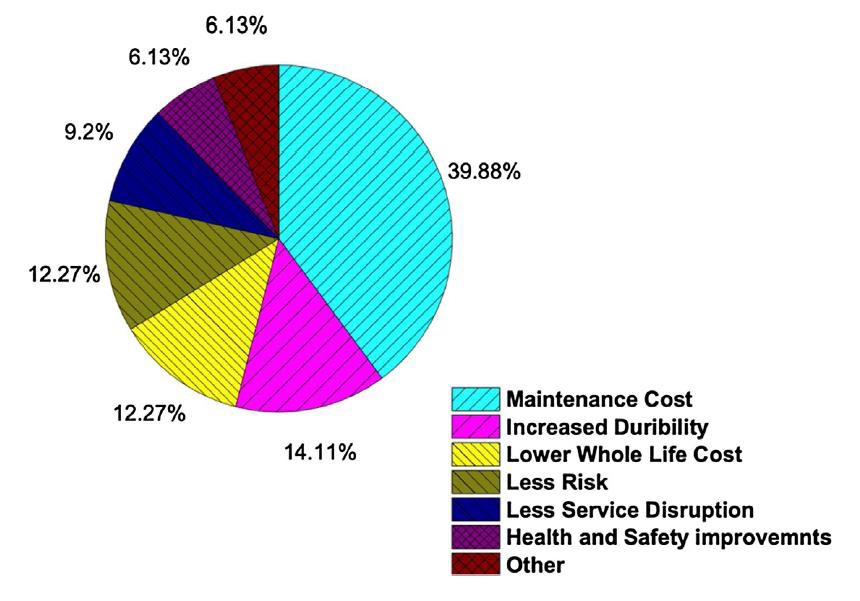

Cracks in concrete have a minor effect on the structure at the beginning, but they can reduce their lifespan later on [16]. Maintenance cost accounts for around 40% of concrete structure maintenance problems as shown in Figure 4 [17].

Figure 4 Issues arise from the maintenance of structures [16].

Several countries are suffering from high concrete maintenance costs. For example, in Denmark maintenance and repair costs are estimated to be around $147/m3 [17]. Moreover, USA spends around $18 to $21 billion on maintenance, repair, and replacement of deteriorated concrete [18]. American Society of Civil Engineers (ASCE) reports that in the upcoming five years, the USA and Asian countries will spend around $2.2 trillion and $2 trillion on the maintenance of structures, respectively [19].

Self-healing concrete technologies have the potential to cut costs at a large scale, especially for applications where leakage is a major issue. Since concrete cracks will be healed autonomously before it further propagates, this technology has the potential to reduce shrinkage, thus reducing reinforcement costs [20]. The self-healing concrete market size worldwide is expected to reach $1,375,088 in 2025, from $216,720 in 2017 [21]. However, this technology is considered relatively young and it has to tackle a few challenges before it becomes a feasible and reliable tool in engineering applications.

5 Challenges facing self-healing concrete in the Middle East Region #

There are many challenges that are facing the large-scale implementation of biocementation techniques for self-healing concrete in general. Concrete is subject to harsh conditions such as high alkalinity, and high temperatures in hot climates

accompanied with limited oxygen supply [22]. These conditions will affect the molecular mechanisms involved in the healing process as well as choosing the suitable microorganisms for the intended application.

This section will focus on the effect of high temperatures on the biological treatment of concrete. Middle East region is known for high temperatures and climatic conditions, especially in summer. The effect of high temperature on biotreatment and biological treatment must be well understood before wide applications of this technology regionally.

It was reported that factors such as the bacterial species, initial concentration of the reagents, reaction temperature, and the pH of the environment, highly affect the activity of the urease enzyme, thus it has a high impact on the precipitation process [23]. However, the bacteria that produce the urease can endure high temperatures and long periods of inactivation in concrete before the cracks occur. This ability is attributed to the bacteria being able to form spores that help the bacteria survive under harsh conditions [22].

Although Urease was found to be most active at a temperature of 60 °C [24-26], there was no observed precipitation at this degree of treatment [8], [27]. It was even confirmed by some studies that the urease activity has no significant correlation with the engineering properties obtained from MICP treatment [28].

Kim et al. [29] studied two types of bacteria (Staphylococcus saprophyticus and Sporosarcina pasteurii), and the results show both species were sensitive to temperature. Based on testing over a wide temperature range (20- 50 °C), 30 °C was optimum for the maximum precipitation mass of calcite. Also, Ryparová et al. [29] study show that 30 °C is optimal for the bacterial reaction. In contrast, Kong et al. [31] found that higher temperatures of up to 55°C is optimum to maximize MICP treatment efficiency. With that said, more calcite production does not necessarily mean better binding ability [32]. Another factor affecting the strength of the cementation is the resulting crystal size which highly depends on the temperature and pH. [33]. The threshold of 60°C was confirmed in another study for self-healing mortars. The self-healing enhancement of mortars increased gradually when temperatures increased from 10 °C to 50 °C, but when temperature increased to 60 °C the self- healing capability decreased significantly [34].

Reinhardt & Jooss [35] tested the water permeability of pre-cracked high-strength concrete after MICP treatment. The treatment efficiency was evaluated at various temperature levels of 20, 50, and 80 °C. The study concluded that higher temperature leads to a faster rate of concrete healing. However, regardless of the exact level of required temperature for optimum treatment efficiency, maintaining high water content is necessary for the bacterial reaction. It is challenging to maintain a well-hydrated environment at high temperatures in real environment situations [30]. The effect of temperature and weather, in general, could be a great potential for future studies on this topic.

6 Conclusion #

Nature has inspired researchers for several engineering application and biological-based methods to be used as construction materials. Self-healing concrete techniques through EICP and MICP has shown potential for concrete maintenance and preservation for longer service life. These methods rely on the precipitation of calcium carbonate into concrete cracks. Sealing these cracks can be used in maintenance since it will help block water leakage and harmful chemicals from seeping into the concrete matrix. Thereby, these methods are capable of increasing the durability of concrete and lengthening its life span.

This method has many benefits such as reducing CO2 emissions from concrete production as well as production cost and downtime of structures. However, several challenges are still facing the wide application of these methods in the field. One of these challenges, especially in the middle east region, is the effect of high temperatures on the treatment reaction. Although the bacteria seem to endure harsh environments with their inherited survival mechanisms, further study is required to fully understand their behavior in real environment applications.

References #

- M. Al-Samarai, “Durability of Concrete in the Arabian Gulf,” J. Mater. Sci. Eng. A, vol. 5, no. 12, 2015.

- A. A. Bubshait, B. M. Tahir, and M. O. Jannadi, “Use of microsilica in concrete construction,” Build. Res. Inf., vol. 24, no. 1, pp. 41–49, Jan. 1996.

- M. Araújo et al., “Cross-linkable polyethers as healing/sealing agents for self-healing of cementitious materials,” Mater. Des., vol. 98, Mar. 2016.

- J. Feiteira, E. Gruyaert, and N. Belie, “Self-healing of moving cracks in concrete by means of encapsulated polymer precursors,” Constr. Build. Mater., vol. 102, pp. 671–678, Jan. 2016.

- H. X. D. Lee, H. S. Wong, and N. Buenfeld, “Self-sealing of cracks in concrete using superabsorbent polymers,”Cem. Concr. Res., vol. 79, pp. 194–208, Jan. 2016.

- M. G. Arab, “Soil Stabilization using Calcium Carbonate Precipitation via Urea Hydrolysis,” in In Proceedings of the 4th World Congress on Civil, Structural, and Environmental Engineering (CSEE’19), Apr. 2016.

- V. S. Whiffin, “Microbial CaCO3 precipitation for the production of biocement.” Murdoch University, 2004.

- M. Nemati and G. Voordouw, “Modification of porous media permeability, using calcium carbonate produced enzymatically in situ,” Enzyme Microb. Technol., vol. 33, no. 5, pp. 635–642, 2003.

- J. Larsen, M. Poulsen, T. Lundgaard, and M. Agerbaek, “Plugging of Fractures in Chalk Reservoirs by Enzyme- Induced Calcium Carbonate Precipitation,” SPE Prod. Oper., vol. 23, no. 04, pp. 478–483, 2008.

- S. A. Abo-El-Enein, A. H. Ali, F. N. Talkhan, and H. A. Abdel-Gawwad, “Application of microbial biocementation to improve the physico-mechanical properties of cement mortar,” HBRC J., vol. 9, no. 1, pp. 36–40, 2013.

- T. Manzur, F. Rahman, S. Afroz, R. S. Huq, and I. H. Efaz, “Potential of a microbiologically induced calcite precipitation process for durability enhancement of masonry aggregate concrete,” J. Mater. Civ. Eng., vol. 29, no. 5,pp. 1–12, 2017.

- R. V. Kulkarni, V. Sreedhar, S. Mutalik, C. M. Setty, and B. Sa, “Interpenetrating network hydrogel membranes of sodium alginate and poly(vinyl alcohol) for controlled release of prazosin hydrochloride through skin,” Int. J. Biol. Macromol., vol. 47, no. 4, pp. 520–527, 2010.

- A. Dakhane et al., “Crack healing in cementitious mortars using enzyme-induced carbonate precipitation: Quantification based on fracture response,” J. Mater. Civ. Eng., vol. 30, no. 4, pp. 1–10, 2018.

- S. S. Bang, J. J. Lippert, U. Yerra, S. Mulukutla, and V. Ramakrishnan, “Microbial calcite, a bio-based smart nanomaterial in concrete remediation,” Int. J. Smart Nano Mater., vol. 1, no. 1, pp. 28–39, 2010.

- J. Wang, H. Soens, W. Verstraete, and N. Belie, “Self-healing concrete by use of microencapsulated bacteria spores,” Cem. Concr. Res., vol. 56, pp. 139–152, Feb. 2014.

- H. Mihashi and T. Nishiwaki, “Development of engineered self-healing and self-repairing concrete-state-of-the-art report,” J. Adv. Concr. Technol., vol. 10, no. 5, pp. 170–184, 2012.

- A. Danish, M. A. Mosaberpanah, and M. U. Salim, “Past and present techniques of self-healing in cementitious materials: A critical review on efficiency of implemented treatments,” J. Mater. Res. Technol., vol. 9, no. 3, pp. 6883–6899, 2020.

- Z. Li, C. Leung, and Y. Xi, Structural renovation in concrete. CRC Press, 2009.

- B. Mather and J. Warner, “Why do concrete repairs fail,” Interview held Univ. Wisconsin, Dept. Engrg. Prof. Dev. MD, WI,< http//aec. engr. wisc. edu/resources/rsrc07. html>. Accessed, 2003.

- Basilisk, Case Study: Reduction steel reinforcement, vol. BR1401. 2020.

- V. Banik, “Self-healing Concrete Market by Type (Intrinsic Healing, Capsule based Healing, Vascular Healing) by End User (Residential & Commercial, Industrial, and Civil Infrastructure): Global Opportunity Analysis and Industry Forecast, 2018 – 2025,” 2019.

- Y. S. Lee and W. Park, “Current challenges and future directions for bacterial self-healing concrete,” Appl. Microbiol. Biotechnol., vol. 102, no. 7, pp. 3059–3070, 2018.

- G. D. O. Okwadha and J. Li, “Optimum conditions for microbial carbonate precipitation,” Chemosphere, vol. 81, no. 9, pp. 1143–1148, 2010.

- W.-S. Ng, M.-L. Lee, and S.-L. Hii, “An overview of the factors affecting microbial-induced calcite precipitation and its potential application in soil improvement,” World Acad. Sci. Eng. Technol, vol. 62, no. 2, pp. 723–729, 2012.

- K. L. Sahrawat, “Effects of temperature and moisture on urease activity in semi-arid tropical soils,” Plant Soil, vol. 78, no. 3, pp. 401–408, 1984.

- L. Cheng, M. A. Shahin, and J. Chu, “Soil bio-cementation using a new one-phase low-pH} injection method,” Acta Geotech., vol. 14, no. 3, pp. 615–626, Oct. 2018.

- V. Rebata-Landa, “Microbial activity in sediments: effects on soil behavior (PhD Dissertation),” Georgia Institute of Technology, 2007.

- A. Mahawish, A. Bouazza, and W. P. Gates, “Factors affecting the bio-cementing process of coarse sand,” Proc. Inst. Civ. Eng. Improv., vol. 172, no. 1, pp. 25–36, 2019.

- G. Kim, J. Kim, and H. Youn, “Effect of Temperature, pH, and Reaction Duration on Microbially Induced Calcite Precipitation,” Appl. Sci., vol. 8, no. 8, p. 1277, 2018.

- P. Ryparová, P. Tesárek, H. Schreiberová, and Z. Prošek, “The effect of temperature on bacterial self-healing processes in building materials,” IOP Conf. Ser. Mater. Sci. Eng., vol. 726, no. 1, pp. 1–6, 2020.

- K. Henry, Ting, Pek, K. Khairul, Anuar, U. Murtala, Z. Muttaqa, Uba, M. Abubakar, Sadiq, and A. Kamarudin, “Microbially induced carbonate precipitations to improve residual soil at various temperatures,” Bull. Geol. Soc. Malaysia, vol. 67, no. June, pp. 75–81, 2019.

- L. Cheng, M. A. Shahin, R. Cord-Ruwisch, M. Addis, T. Hartanto, and C. Elms, “Soil stabilisation by microbial- induced calcite precipitation (micp): investigation into some physical and environmental aspects,” in 7th International Congress on Environmental Geotechnics: iceg2014, 2014, p. 1105.

- T. Jones and R. L. Detwiler, “Fracture-aperture alteration induced by calcite precipitation,” in 49th US Rock Mechanics/Geomechanics Symposium, 2015.

- W. Du et al., “Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate,” Constr. Build. Mater., vol. 247, p. 118575, 2020.

- H. W. Reinhardt and M. Jooss, “Permeability and self-healing of cracked concrete as a function of temperature and crack width,” Cem. Concr. Res., vol. 33, no. 7, pp. 981–985, 2003.