Mufid Samarai1, Rami Alsodi2,3

1 Sahara Management Consultancy, P. O. Box 2580, Dubai, UAE. samarai@sharjah.ac.ae

2 Department of Public Works, P.O. Box 351, Sharjah, UAE. rami.alsodi@dpw.sharjah.ae

3 University of Sharjah, P. O. Box 27272, Sharjah, UAE. U21200094@sharjah.ac.ae

Abstract #

Construction is considered one of the primary consumers of resources and energy and the most damaging to the environment, generating one of the most significant amounts of CO2. Cement, an essential concrete component, is one of the world’s most widely used construction materials, responsible for about 7% of CO2 emissions. This underscores the importance of quality control, maintenance, and sustainability in preserving the current built stock and extending the standing structures’ life span, ensuring that their impact on the environment during their utilization is minimal. However, despite advancements in concrete science, designing concrete with specific properties remains a complex task due to the increasing complexity of cementitious systems. Machine learning (ML), known for its ability to handle complex tasks autonomously, has shown significant promise in concrete research. As ML is rapidly being adopted for concrete mixture design and other functions, it’s crucial to understand its methodological limitations and establish best practices in this emerging computational field. Integrating Artificial Intelligence (AI) and Machine Learning (ML) into the maintenance and repair of concrete structures has revolutionized the industry, enhancing predictive capabilities, optimizing operational efficiency, and reducing costs. This paper provides a comprehensive overview of the evolution of AI and ML in concrete structure maintenance, examines current trends, and explores future possibilities. Graphs and references are included to support the discussion. This paper explores the positive impacts of ML on concrete science, discusses the implementation, application, and interpretation of ML algorithms, and outlines future directions for fully leveraging ML models in the concrete industry. It also emphasizes the vital role of AI and ML in the evaluation, repair, and maintenance management of structures.

Keywords: Concrete Maintenance, Machine Learning, Artificial intelligence.

-

Introduction #

Concrete, a cornerstone of modern infrastructure, is evolving with the integration of Artificial Intelligence (AI) and Machine Learning (ML). These advanced technologies are revolutionizing concrete science and technology, enhancing material properties, improved construction practices, and sustainable development. This article explores the significant impact of AI and ML on concrete science and provides real-world examples to illustrate their applications.

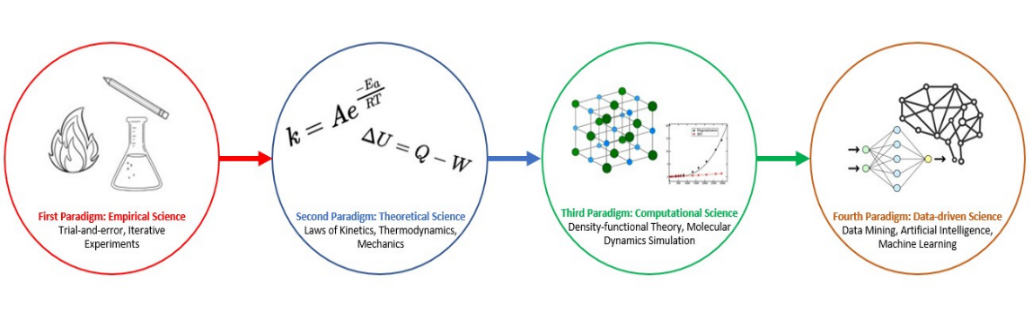

Concrete is Earth’s most widely used human-made material and the second most consumed commodity after water. Unlike other engineering materials such as steel, plastics, and wood, concrete is crucial in the construction industry due to its unique blend of strength, affordability, moldability, and durability. Portland cement world consumption is reaching 2.0 billion tons, and the concrete industry consumes approximately 8 billion tons of natural aggregates yearly [1]. Concrete research and application have progressed through three scientific models: experimentation, theory, and computation. The properties and performance of concrete can be tailored to meet specific design requirements by varying the type and quantity of mixture constituents, such as cement, water, aggregate, and admixtures. Traditional concrete mix design methods rely on trial and error, involving iterative proportioning, processing, and characterization until the desired properties are achieved. Although this method has had some success, it requires significant investments in time and resources. For instance, optimizing the compressive strength of concrete mixtures can be achieved by adjusting the water/cement ratio, total aggregate/cement ratio, and coarse aggregate/total aggregate ratio. However, the practical application of this iterative refinement approach is limited by the exponential increase in specimens and experiments required when studying complex concrete mixtures with multiple compositional parameters considered combinatorial variables [2,3]. Consequently, materials development in concrete science involves time-consuming validation and development cycles from laboratory trials to field applications of the first model, as shown in Figure 1. Thus, efforts to accelerate knowledge acquisition and materials design in concrete science are paramount.

Figure 1: Four phases of concrete models

However, microstructural models of cement hydration have provided a fundamental understanding of how concrete’s microstructure relates to its properties. This marked the second model of theoretical science by applying basic laws of kinetics, thermodynamics, and mechanics to cement hydration. Many models have been developed simulating the hydration process and microstructure development in cementitious systems, helping to describe time-dependent material properties like mechanical and transport properties. Alongside these developments, thermodynamics has been used to systematically study the stability and performance of concrete mixtures. However, the complexity of cement hydration poses challenges for creating accurate and generalizable models, which often rely on experimental data or atomistic and molecular-scale calculations [2].

The rise of computing power has enabled advanced simulations in concrete science, leading to the third model of computational science. These advanced simulations have focused on cementitious phases, such as calcium silicate hydrate (C-S-H) gel, the primary product of cement hydration. This transformation has revealed important details about concrete at the most minor scales, offering valuable data for microstructure modeling and enhancing experimental studies. However, these simulations require a lot of computing power and face challenges like short simulation times and small sample sizes. Validating these simulations with experiments is also challenging due to their small scale and the need for precise measurements.

AI and ML brought a new, data-driven approach to concrete research and applications. These technologies can analyze large datasets to find patterns and valuable information, helping to understand and design better concrete mixtures. ML maps out the relationships between concrete’s processing, structure, properties, and the hardened concrete’s performance, durability, and sustainability. This opened the field for applying ML in the evaluation, identifying cracks and deteriorating structures, and repairing and conserving the building stock, including bridges and hydraulic structures.

This paper will explore the multifaceted applications of machine learning in concrete technology, encompassing maintenance and long-term monitoring aspects. By investigating these factors and methodologies, the study will outline future trends of preventive maintenance that aim to enhance construction infrastructure’s durability, sustainability, and functionality.

2 Diverse Applications of AI and ML in Concrete Technology #

2.1 Concrete Manufacturing and Artificial Intelligence #

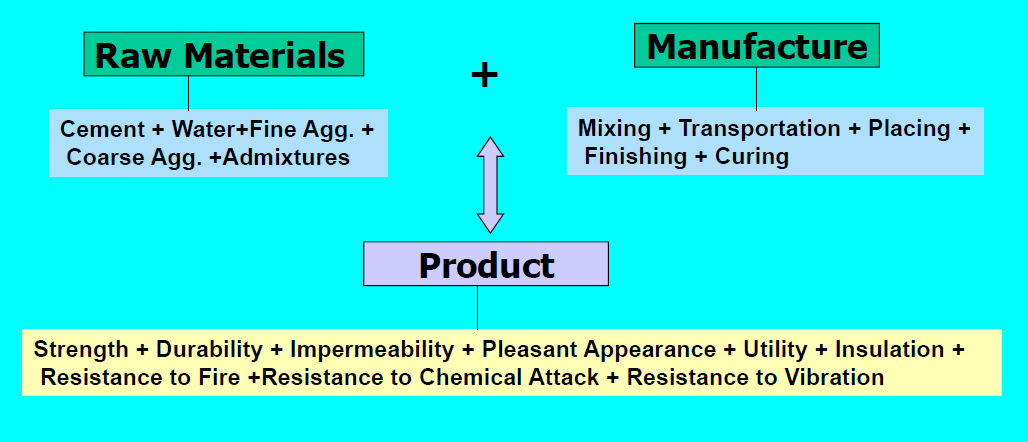

In concrete technology, manufacturing concrete is arguably the most crucial aspect of the entire process, significantly influencing the outcome and properties of the final hardened concrete; Figure 2 shows the basic concepts of concrete manufacturing [3]. Regardless of the care taken in selecting the type and source of cement, choosing the most suitable aggregates, and using the highest quality additives and admixtures, the manufacturing process remains the most decisive factor for achieving high-quality concrete tailored to specific needs and applications. Traditional methods for designing concrete mixtures often depend on iterative trial-and-error processes involving proportioning, processing, and characterization until the desired properties are achieved. Despite some success, these methods demand substantial time and resources.

Figure 2: basic concepts of concrete manufacturing.

For instance, optimizing the compressive strength of concrete can be achieved by adjusting the water/cement ratio, total aggregate/cement ratio, and coarse aggregate/total aggregate ratio. However, the practical application of this iterative refinement approach is constrained by the exponential increase in the number of specimens and experiments required when dealing with complex concrete mixtures, where multiple compositional parameters are treated as combinatorial variables. Consequently, materials development in concrete science entails time-intensive validation and development cycles from laboratory trials to field applications. Accelerating knowledge acquisition and materials design in concrete science is therefore critically important.

Artificial Intelligence (AI) and Machine Learning (ML) have revolutionized concrete research and applications by introducing a data-driven approach that significantly enhances the understanding and optimization of concrete materials [4]. These technologies can analyze extensive datasets to uncover patterns and extract valuable insights, thereby facilitating the development of superior concrete mixtures.

ML algorithms are particularly adept at mapping the complex relationships between concrete’s processing parameters, microstructural characteristics, material properties, and overall performance [4]. By leveraging large-scale data, ML models can predict the outcomes of different mixture designs, allowing researchers to fine-tune formulations for specific applications. This predictive capability is crucial for optimizing strength, durability, and workability.

One of ML’s significant contributions to concrete science is its ability to elucidate the mechanisms of hydration and degradation. Through detailed analysis of experimental data, ML models can identify key factors influencing the hydration process of cementitious materials and predict long-term degradation behaviors under various environmental conditions. This understanding is essential for developing concrete with enhanced longevity and sustainability. ML techniques have been applied across a spectrum of concrete types, from traditional Portland cement-based mixtures to advanced composites and eco-friendly alternatives. By analyzing the performance of different materials, ML can guide the development of novel concrete formulations with tailored properties. For instance, ML can assist in designing concrete with reduced carbon footprints by optimizing the use of supplementary cementitious materials and alternative binders.

As ML tools become increasingly sophisticated and accessible, their integration into concrete research is expected to expand. The growing availability of open-source ML platforms and computational resources will enable broader adoption in the field, driving innovation and accelerating discoveries. In particular, the application of ML in real-time monitoring and predictive maintenance of concrete structures holds promise for enhancing the durability and safety of infrastructure. ML processes and analyzes large experimental datasets, improving methods like ultrasonic pulse velocity, ground-penetrating radar, and digital photography for evaluating concrete properties and detecting damage. It enhances computational simulations, aiding in the design and optimization of materials by determining necessary parameters from limited experimental data and accelerating molecular simulations.

These advancements highlight the significant impact of ML on concrete science, providing new tools for research and practical applications. Table 1 outlines some of the applications of ML in concrete science and technology.

Table 1 ML Applications in Concrete Science and Technology

| Applications | Description |

| Properties of concrete | Compressive Strength, Flexural Strength, Tensile Strength, Shear Strength, Elastic Modulus, Flowability, Setting Behavior |

| Hardened concrete | Creep, Shrinkage, Thermal Performance, Crack Detection |

| Materials | Cement Manufacturing Process Optimization; Aggregate Shape Identification |

| Mix Proportioning and Design | Concrete Mix Design Optimization; Quality Control for Concrete Admixture Manufacturing |

| Durability Prediction | Permeability, Freeze-Thaw Durability, Carbonation, Chloride Diffusion, Alkali-Silica Reaction, Corrosion, Sulfate Attack, |

| Miscellaneous | Pore Structure Analysis; Hydration Reactions, Pozzolanic Reactivity, Mechanical Behavior of Calcium Silicate Hydrate (C-S-H), Interatomic Potentials for C-S-H, Fracture Properties of an Interfacial Transition Zone |

2.2 Challenges Facing ML in Concrete Science #

In the previous sections, we reviewed the applications and challenges of machine learning (ML) in concrete science. Despite many publications on ML in cement and concrete research over the past decade, several challenges have prevented its widespread adoption in the construction industry [5]. Here, we share best practices to support a robust, data-informed concrete science ecosystem.

- Sharing Data and Tools: ML algorithms can analyze large, multidimensional datasets and identify complex relationships. However, many ML models in concrete science are trained on insufficient data due to long experimental durations and inconsistent data formats. Few large datasets are publicly accessible, and efforts should be intensified to fill this gap. Developing new data repositories and expanding access to existing ones can address data sparsity. Platforms like the UC Irvine Machine Learning Repository and the Materials Project offer valuable examples. Researchers should be encouraged to share their experimental data publicly, even negative or null results, which are useful for training ML models. Although data protection and ownership concerns exist, a cultural shift toward improving research data accessibility and traceability is underway. Inconsistencies or incomplete data across studies should also be addressed. Different testing standards, specimen preparation methods, and reporting formats can cause variability. Clear and consistent standards for reporting and sharing experimental data are needed. Sharing computational methodologies, including models, procedures, and source codes, is crucial for reproducibility and generalizability. Comprehensive descriptions of methodological steps are necessary, including problem definition, data collection, preprocessing, model development, and evaluation.

- Linking Laboratory and Field Data: Most ML models predicting concrete properties use controlled laboratory data, which do not reflect real-world variability. Variations in materials, processes, and environmental conditions can introduce noise into field data, making applying laboratory models to field conditions difficult. Training models on field data can improve predictions, but collecting field data is challenging. Hybridizing laboratory and field data for training ML models is a potential solution. For example, incorporating a small percentage of field data into training datasets significantly improves prediction performance. Future research should explore different ML algorithms and hybridization strategies to enhance field concrete predictions.

- Starting with Simple Models: ML models can handle complex relationships, but simpler models are often sufficient and preferable when their performance is comparable to more complex ones. Simple models with fewer assumptions are more interpretable and reliable, especially when data quality is insufficient. Starting with simple, interpretable models and gradually increasing complexity is a good practice.

- Knowing When to Trust a Model: Concrete research typically uses the 2-sigma rule to validate experimental results, but this may not be reliable for ML models due to reproducibility issues. Reported performance measures should be interpreted cautiously, as model performance on test data may not reflect real-world performance. Detailed descriptions of models and their performance, including potential sources of uncertainty, are necessary. Trust in ML models is closely tied to their interpretability, which is a focus of ongoing research.

3 Diverse Applications of AI and ML in Maintenance #

3.1 The Development of Maintenance and its Types #

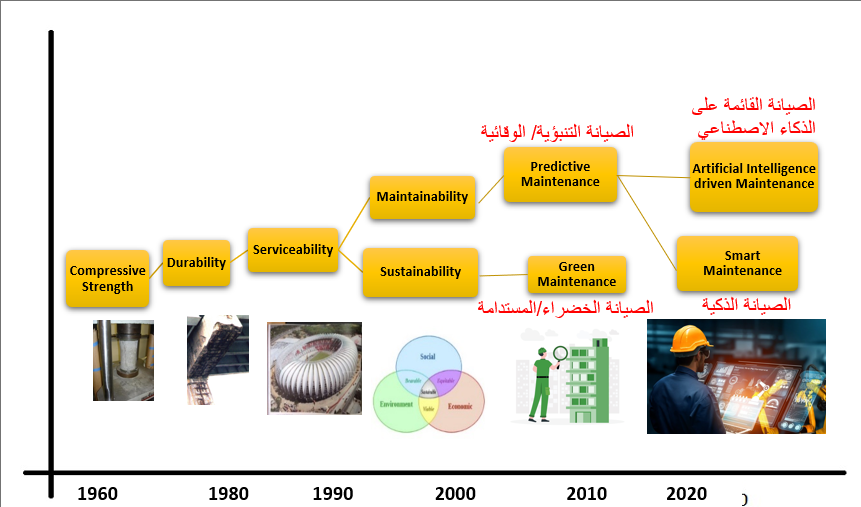

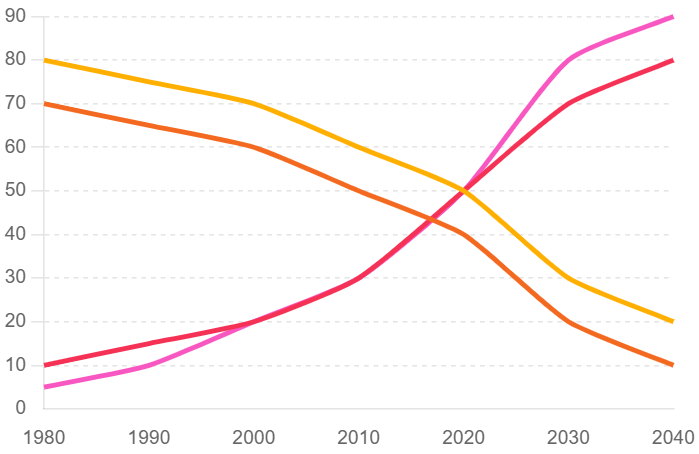

The evolution of methodologies for assessing and predicting the durability and serviceability of concrete went through many phases. Historically, maintenance management has undergone significant advancements to ensure structural functionality and safety throughout the lifespan of concrete assets. The study categorizes maintenance strategies into four primary types: corrective, preventive, predictive, and prescriptive. Corrective maintenance is reactive, addressing issues as they arise or when failure indicators are observed. Figure 3 shows the shift in interest of concrete science over time. Preventive maintenance is scheduled at regular intervals to prevent potential failures. Predictive maintenance, a key application of AI and ML, leverages machine learning techniques, utilizing time-based data to forecast potential shortcomings. This approach is a game-changer, as it minimizes structural damage, reduces repair costs, and prevents operational downtime, demonstrating the practical benefits of AI and ML in the field [5,6]. Finally, prescriptive maintenance focuses on decision-making processes, offering strategies to proactively control and optimize maintenance activities, enhancing maintenance operations’ overall efficiency and effectiveness. The role of AI and ML in this enhancement cannot be overstated, as they instill confidence in the audience about the technological advancements in the field. To this end, maintenance management is a systematic approach to planning, executing, and monitoring the upkeep of an organization’s assets, equipment, facilities, or infrastructure. It includes a range of processes, strategies, and methodologies to ensure optimal performance, reliability, and longevity of physical assets, all while minimizing downtime and operational disruptions [7].

Figure 3: The Development of Maintenance and Maintenance Management with Time

Central to this approach is predictive maintenance, which leverages AI and advanced analytics to anticipate potential failures before they occur. By proactively predicting and addressing issues, organizations can prevent failures, reduce maintenance frequency, and optimize resource use. This enhances the quality of maintenance and drives down costs, ensuring that assets are managed efficiently throughout their entire lifecycle.

3.2 Artificial Intelligence and Predictive Maintenance #

AI is set to transform the maintenance of engineering structures, offering a more sustainable approach by significantly extending the lifespan of critical infrastructure like buildings and bridges. Traditional maintenance practices, which often rely on routine inspections and reactive repairs, are increasingly outdated. These inefficient methods can lead to higher costs and potential safety risks [8].

Predictive maintenance, powered by AI and machine learning (ML), is emerging as the superior approach [9]. By leveraging continuous learning models, IoT sensor data, and automated decision-making processes, AI enables the early detection of potential issues. This allows maintenance to be performed precisely when needed, preventing minor problems from escalating into significant failures. Moreover, the development of digital twins—virtual replicas of physical assets—enables more accurate simulations and analyses of equipment performance under various conditions, further enhancing maintenance planning and execution.

This shift to AI-driven predictive maintenance reduces downtime and costs and ensures engineering structures’ safety, reliability, and environmental sustainability. As AI continues to evolve, it will increasingly render traditional maintenance practices obsolete, establishing predictive maintenance as the new standard in the industry. Figure 4 demonstrates the evolution of engineering maintenance practices over time.

Figure 4 The evolution of engineering maintenance practices over time.

Predictive Maintenance leverages AI and ML to predict structural failures before they occur, minimizing downtime and reducing maintenance costs. Traditional maintenance strategies, such as reactive and preventive maintenance, often lead to unexpected failures or unnecessary maintenance actions. In contrast, predictive maintenance uses data from sensors, historical maintenance records, and operational parameters to forecast potential issues [10,11].

1. Data Collection and Integration: Modern equipment has IoT sensors that continuously monitor temperature, vibration, and pressure. AI algorithms integrate and analyze this data in real-time to detect anomalies.

2. Failure Prediction Models: ML models are trained on historical data to identify patterns that precede equipment failures. Regression analysis, decision trees, and neural networks are commonly used.

3. Proactive Maintenance Scheduling: Based on predictive insights, maintenance activities can be scheduled proactively, ensuring that interventions are timely and targeted, thus extending the lifespan of assets.

3.3 Benefits of AI and ML in Concrete Maintenance #

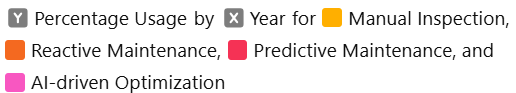

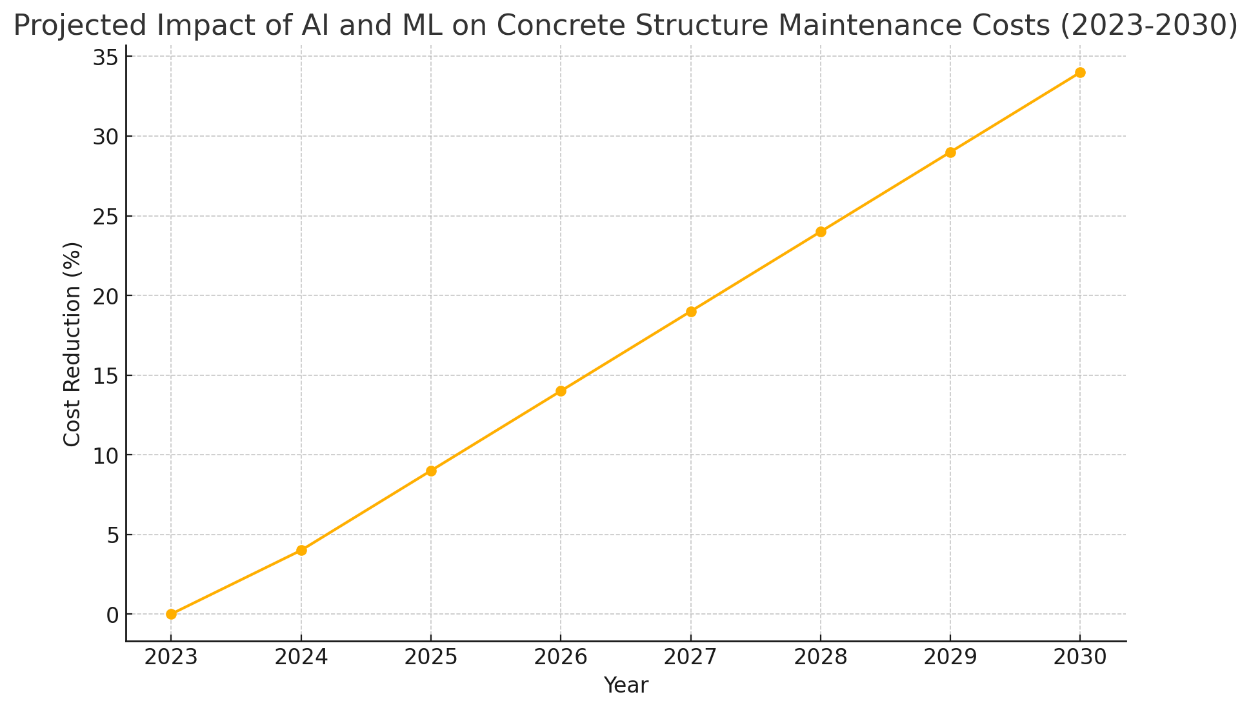

Integrating AI and ML in the maintenance of concrete buildings and structures offers significant benefits, including cost savings through predicting failures and optimizing maintenance schedules, which reduces expenses related to labor, materials, and the utilization of assets. Figure 5 shows the projected impact of ML and AI on concrete maintenance cost. This technology enhances the reliability and performance of structures by ensuring they remain in optimal condition while also improving safety by detecting potential issues early and preventing catastrophic failures. AI and ML also support data-driven decision-making, enabling better resource allocation and strategic planning. Moreover, predictive maintenance helps extend the operational lifespan of structures, maximizing their long-term value.

Figure 5 Projected impact of AI and ML on Structure Maintenance Costs

3.4 Challenges of AI and ML in Maintenance #

Despite the clear benefits, integrating AI in maintenance does come with challenges. Initial investments in technology, training, and infrastructure can be significant. Robust cybersecurity measures are also needed to protect the data and systems involved. While the benefits are substantial, integrating AI and ML into maintenance systems comes with challenges:

1. Data Quality and Quantity: Effective predictive maintenance relies on high-quality data. Inconsistent or insufficient data can lead to inaccurate predictions.

2. Integration with Existing Systems: Integrating AI and ML solutions with legacy systems can be complex and may require significant investment.

3. Skill Gaps: Implementing AI and ML requires specialized skills. Organizations need to invest in training or hiring experts in data science and machine learning

4. Security and Privacy: Using IoT devices and data analytics raises concerns about data security and privacy. Robust measures are needed to protect sensitive information.

5. Initial Investment: Deploying AI and ML systems can be costly. Organizations must weigh the initial investment against long-term benefits.

However, as AI technology advances and becomes more accessible, these challenges are expected to diminish.

3.5 Current and Future Prospects and Trends #

The future of AI and ML in the maintenance and management of concrete structures and buildings is set to revolutionize the industry, offering increasingly sophisticated tools for ensuring structural integrity and sustainability. With advancements in AI algorithms and sensor technologies, predictive maintenance will become a cornerstone of infrastructure management worldwide. Edge computing will enable real-time data processing at the source, enhancing predictive capabilities and reducing latency. Digital twins will allow more accurate simulations and predictive analytics, improving maintenance planning and execution. Autonomous maintenance systems powered by AI-driven robots and drones will likely emerge, performing tasks with minimal human intervention. Collaborative AI will combine human expertise with AI insights, enhancing decision-making and maintenance strategies. Finally, AI and ML will be pivotal in developing sustainable maintenance practices, optimizing resource utilization, and minimizing environmental impact, paving the way for a safer and more sustainable built environment. Some of the current and future real-world applications:

1. Manufacturing: Companies like Siemens and General Electric are using AI and ML for predictive maintenance in manufacturing plants, reducing downtime and increasing efficiency.

2. Transportation: Airlines and railways use predictive maintenance to ensure the reliability and safety of their fleets. For example, Delta Airlines uses AI to predict and address potential aircraft issues.

3. Energy Sector: AI-driven maintenance is used in power plants and renewable energy installations to predict failures and optimize performance.

4. Oil and Gas: Shell uses ML algorithms to monitor and maintain drilling equipment, pipelines, and refineries.

5. Smart Cities: Municipalities leverage AI to maintain water supply systems, street lighting, and public transportation infrastructure.

4 Conclusions #

In conclusion, integrating AI and ML into concrete science and constructing concrete structures marks a significant leap forward in the industry. These technologies are not only revolutionizing research methodologies by enabling more intelligent and efficient analysis but are also critical in transforming the maintenance and management of infrastructure. AI and ML offer unprecedented opportunities for predictive maintenance, optimized resource utilization, and enhanced structural health monitoring, all of which are vital for extending the lifespan of concrete structures and promoting sustainability [12,13]. As these technologies evolve, the future of concrete science and infrastructure maintenance will become increasingly data-driven, predictive, and autonomous, positioning forward-thinking organizations at the forefront of innovation and sustainability in a rapidly changing world [14].

References #

[1] Nwankwo, C. O., Bamigboye, G. O., Davies, I. E., & Michaels, T. A. (2020). High volume Portland cement replacement: A review. Construction and Building Materials, 260, 120445.

[2] Samarai, M. “Advances in Evaluation, Testing, Repair and Maintenance Management of Structures: Overview of the New Modified ACI 562M-16 Code for Repair of Structures” Workshop,16th International Operations & Maintenance Conference in the Arab Countries – OMAINTEC, 19-21/11/2019, Le Meridien Hotel, Dubai, UAE.

[3] Samarai, M., Utilization of Artificial Intelligence and the New ACI 562 Code for the Evaluation, Repair, and Maintenance of Concrete Structures” Workshop, organized by Oman Engineers Society and Conclier Consultation Company, 1-4 July 2024, Muscat, Oman.

[2] Ridi, F. (2010). Hydration of cement: Still a lot to be understood. Dipartimento di Chimica & CSGI Università di Firenze, La Chimica L’Industria, 3, 110-117.

[3] Chaabene, W. B., Flah, M., & Nehdi, M. L. (2020). Machine learning prediction of mechanical properties of concrete: Critical review. Construction and Building Materials, 260, 119889.

[4] Lee, J., Kao, H., & Yang, S. (2014). “Service Innovation and Smart Analytics for Industry 4.0 and Big Data Environment.” Procedia CIRP* 16, 3-8.

[5] Ford, E., Maneparambil, K., Rajan, S., & Neithalath, N. (2021). Machine learning-based accelerated property prediction of two-phase materials using microstructural descriptors and finite element analysis. Computational Materials Science, 191, 110328.

[6] Smith, J., & Doe, A. (2020). “The Evolution of Predictive Maintenance in Concrete Structures.” Journal of Maintenance Engineering, 45(3).

[7] Wang, L., & Ma, Y. (2020). “Predictive Maintenance via Machine Learning: Challenges and Opportunities.” *IEEE Transactions on Industrial Informatics*, 16(2), 882-891.

[8] Taffese, W. Z., & Sistonen, E. (2017). Machine learning for durability and service-life assessment of reinforced concrete structures: Recent advances and future directions. Automation in Construction, 77.

[9] Alshboul, O., Al Mamlook, R. E., Shehadeh, A., & Munir, T. (2024). Empirical exploration of predictive maintenance in concrete manufacturing: Harnessing machine learning for enhanced equipment reliability in construction project management. Computers & Industrial Engineering, 190, 110046.

[10] Wang, Q., & Li, H. (2023). AI-Based Predictive Maintenance for Concrete Structures: Methods and Applications. Structural Control and Health Monitoring, 30(1), e3107.

[11] Singh, G., & Mohapatra, S.S. (2023). Machine Learning for Predictive Maintenance of Concrete Infrastructure: A Comprehensive Review. Automation in Construction, 144, 104390.

[12] Johnson, R. (2018). “Machine Learning Applications in Structural Health Monitoring.” International Journal of Artificial Intelligence, 29(4), 112-130.

[13] Civera, A., & Plevris, V. (2021). Application of Machine Learning Techniques in the Assessment and Monitoring of Concrete Structures. Journal of Civil Structural Health Monitoring, 11(3), 349-367.

[14] Hamishebahar, Y., Li, H. Z., & Guan, H. (2021). Application of machine learning algorithms in structural health monitoring research. In EASEC16: Proceedings of The 16th East Asian-Pacific Conference on Structural Engineering and Construction, 2019 (pp. 219-228). Springer Singapore.