Knezevic Jezdimir MIRCE Akademy, Exeter, EK

Abstract #

The main objective of this paper is to introduce the global maintenance management and engineering community to the body of knowledge contained in MIRCE Science for the innovative approach to maintenance, which is perceived as the management of failures and provision of work. Thus, maintenance manages the consequences of the complex interactions between failure events and maintenance actions are taken that drive the behavior of functional systems, which can be quantified by the MIRCE Functionability Equation. Hence, in the future maintenance managers will be able to perform quantitative trade-offs between feasible failure management options to determine one that would yield the greatest benefit measured through the expected work. To illustrate the advantages of applying MIRCE Science to the maintenance management process a numerical example is provided, where several feasible maintenance options are considered and quantified.

Keywords: MIRCE Science, MIRCE Functionability Equation, quantitative maintenance management

1 Introduction #

The philosophy of MIRCE Science is based on the premise that the purpose of the existence of any functional system1 is to do work. The work is done when the expected measurable function is performed through time. The best way to achieve that is to increase the revenue- generating work done while reducing the resources consumed for it. One way towards that target is to improve the reliability of consisting parts by using appropriate engineering and production methods. Another way is to reduce maintenance time by applying appropriate condition monitoring and data management technologies proposed by maintenance 4.0. Although there are an infinite number of combinations between the number of improvements in reliability and reduction in maintenance time, it is necessary to recognize that the work done by a functional system is driven by their combined impact. Their impact on the amount of work done by a functional system could be quantified through the following two approaches:

- Measuring the work done during the operation process

- Predicting the work during the planning process.

Measuring the work done is a rather straightforward process where the operational hours are counted together with the resources consumed2. However, collecting data regarding the past performance of functional systems does not have any impact on the past revenue, reputation, loyalty, and other measures of a functional system’s effectiveness.

Predicting future performances, at the planning stage, gives an opportunity for any changes necessary to create functional systems with desirable performance to be made, within the

1 Functionable system is operationally defined functional system. [2] 2 Boeing 747, registration number N747PA, which belonged to Pan Am airways, have delivered the work of 80,000 flying hours and received 806,000 maintenance man-hours, during the 22 years of in-service life. [2]

given budget. In return, it will generate the expected return on their investment (e.g. profit, reputation, loyalty, public benefit, and similar). However, to achieve that, it is necessary to have a mathematical model3 that would facilitate that, as mathematics is the only body of knowledge that enables quantitative predictions to be made in all natural sciences, from quantum mechanics (the motions of subatomic particles) to astrophysics (the motion of spacecraft).

Although reliability engineering and maintenance engineering are well-recognized disciplines in their own rights, best to the author’s knowledge there is no body of knowledge for predicting their combined impact on the work done and resources consumed, in a quantitative and comparative manner.

The main objective of this paper is to introduce reliability and maintenance engineers to MIRCE Science, a body of knowledge that enables quantitative prediction of the complex interactions between reliability and maintenance options on the work done and resources required [2]. Hence, by making use of the MIRCE Functionability Equation it is possible to perform a quantitative trade-off between feasible reliability and maintenance options to select the compromising solution that would yield the greatest effectiveness, measured through the work done or expected profit.

2 Brief overview of MIRCE Science #

According to MIRCE Science, at any instant of calendar time, a given functional system could be in one of the following two macro states Knezevic [2]:

- Positive Functionality State (PFS), a generic name for a state in which a functional system is able to deliver the expected measurable function(s),

- Negative Functionality State (NFS), a generic name for a state in which a functional system is unable to deliver the expected measurable function(s), resulting from any reason whatsoever.

In MIRCE Science work done by a functional system is uniquely defined by the trajectory generated by its motion through MIRCE Space4. That motion is driven by functionality actions, which are classified as:

- Positive Functionality Action (PFA) is a generic name for any natural process or human activity that compels a system to move to a PFS. Typical examples are servicing, lubrication, visual inspection, repair, replacement, final repair, examination, partial restoration, inspection, storage, modification, transportation, sparing, cannibalization, refurbishment, health monitoring, restoration, packaging, diagnostics, and similar

- Negative Functionability Action (NFA), is a generic name for any natural process or human activity that compels a system to move to an NFS. Typical examples are thermal aging, actinic degradation, acid reaction, bird strike, warping, abrasive wear, suncups formation on the blue ice runway, fatigue, pitting, thermal buckling, photo-

3 Newton, Maxwell, Lagrange, Boltzmann and other well know and applied equations used as the mathematical models for the predictions of the physical behaviour of natural world. 4 MIRCE Space is a conceptual 3-dimensional space containing infinite set of possible discrete functionability states that a functionable system could be found in, at any instant of the calendar time, and corresponding probabilities. [2]

oxidation, production errors, strong wind, maintenance error, hail damage, lightning strike, COVID-19, quality problems, hard landing, sandstorm and so forth.

The time evolution of a functional system through MIRCE Space is physically manifested through the occurrences of functionality events, which are classified as:

- Positive Functionality Event (PFE), a generic name for any physically observable occurrence in the calendar time that signifies the transition of a functional system from an NFS to a PFS.

- Negative Functionality Event (NFE), a generic name for any physically observable occurrence in the calendar time that signifies the transition of a functional system from a PFS to an NFS.

Consequently, the concept of time evolution in MIRCE Science is conceptualized as the motion of a functional system through functionality states, resulting from any functionality actions whatsoever and the actions required to generate any functionality motion.

3 Mathematical Principles of MIRCE Science #

The ability to “normalize” all competing options of a functional system enables comparisons to be made between them and finally select the best one, in accordance with a given criterion. Hence, MIRCE Science is a body of knowledge that enables quantitative assessment of the impact of the multidimensional interactions between:

- consisting of components (mechanical, electrical, electronics, and so forth)

- system architecture (active and passive redundancies)

- natural environment (temperature, wind, humidity, fog, and many others

- human rules regarding:

- operation process (levels of stress, frequencies of use, and similar)

- maintenance policies: preventive, condition-based, opportunistic, etc.

- support strategies: in-house support, and outsourcing, combined.

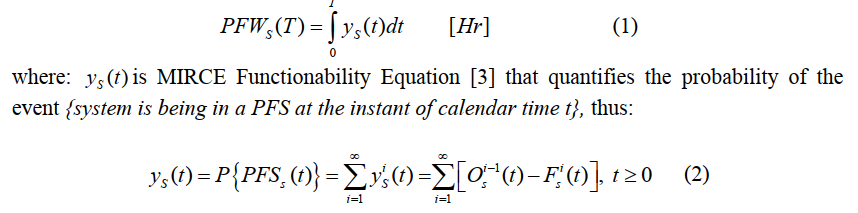

According to the MIRCE Science Philosophia5 positive work is done when a functional system is delivering a functionality performance, which means that it must be in a PFS. According to Knezevic [2] the expected positive work to be done by a functional system during a given interval of calendar time T, PFWs(T), measured in calendar hours, Hr, can be calculated by making use of the following equation:

5 In Greek, philosophia "love of knowledge, pursuit of wisdom; systematic investigation," from philo- "loving" +sophia "knowledge, wisdom

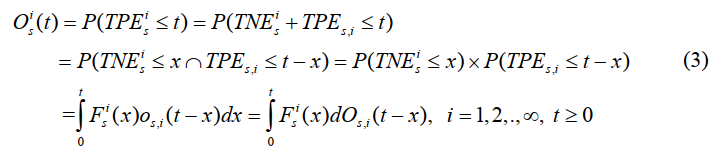

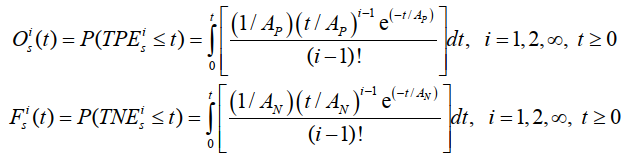

The infinite sum of positive and negative functions represents a mathematical scheme that in MIRCE Science defines the sequential occurrences of the functionality events in the direction of the calendar time, for each feasible variation of the functional system considered. In the language of mathematics, these are systems of convolution integrals. Thus, the sequential positive functionality function, Osi (t) , which defines the probability that the life of a functional system, will take place before or at the instant of calendar time t, is defined by the following convolution integrals [2]:

In order for the ith sequential positive functionability event, PFEi, to take place before, or at the instant of calendar time t, it is necessary that the previous functionality event, which in this case is NFEi, takes place sometime before time t, denoted by x in the above expression. Then, the sequential PFEi has to take place during the remaining interval of calendar time, which in this case is denoted with t-x.

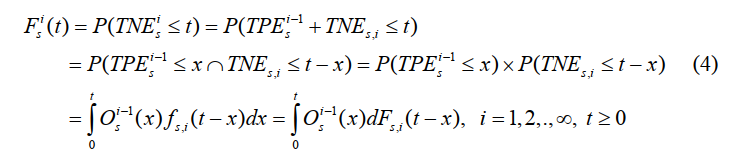

The process of defining the negative sequential distribution Function, which defines the probability that the ith sequential NFES of a functional system will take place before or at an instant of calendar time t, follows the same mathematical principle. Thus, the sequential negative functionality functions are fully defined in the following way:

This multidimensional set of convolution integrals defines the motion of a functionable system through MIRCE Space, depicting and passing through each sequential functionality state in the direction of calendar time, generating a trajectory unique to each functional system, [5]. Thus, the same set of generic equations, when applied to different operational and maintenance policies generate different trajectories of the motion through MIRCE Space, which means different functionality performance, namely different work done and different resources consumed. Hence, Knezevic [2] has created a generic platform on which each feasible plan for the operation and maintenance policies and strategies would generate its own future “trajectory” for a system under consideration.

4 Maintenance management options: An illustrative Example #

To illustrate the applicability of MIRCE Science to the reliability engineering design process the quantitative assessment of the combined impact of reliability and maintenance on the performance of a functional system, a hypothetical example will be used.

The simplest possible functional system consists of one component that exists in two functional states, namely PFS and NFS. Even further, a single positive or negative action causes the occurrences of positive and negative events at which the functional system changes its functional states.

It is necessary to stress that this example is chosen, not because the real functional systems consist of a single component, but because it is extremely useful for the understanding of the mathematical scheme that defines the motion of a functional system through MIRCE Space. This knowledge, in turn, quantifies its expected functionality performance, namely the expected work done, and corresponding resources consumed.

To demonstrate the applicability of the MIRCE Science mathematical scheme to the quantitative assessment of the combined impact of reliability engineering and maintenance management decisions on the performance of a functional system the following three options for the future system are addressed:

Option 1: Basic engineering design: The functional system under consideration is expected to experience an occurrence of an NFE during a continuous operation with the expected value of E[TNES,] =1080 Hr. What is the amount of positive work expected to be delivered during a calendar year of continuous operation, without performing any maintenance action?

Option 2: Adding Maintenance actions: What would be the additional work done if the system is designed in a way that maintenance actions could be performed after occurrences of failures? Assume that the design-in-maintenance action that returns a functional system to PFS has the expected value of E[TPES,]=168 Hr.

Assuming that options 1 and 2 are not satisfied system engineering requirements, an additional amount of money has been allocated to the project. Contributing engineering departments have been asked to make the proposal for the increase of the expected work done, for a given extra budget. The following two proposals were made:

- Option 3: The Reliability Engineering department submitted a proposal in which they were stating that by investing the additional funds allocated into new technology in the manufacturing process it is possible to extend the basic design expected life of component A by 50%.

- Option 4: The Maintenance Engineering department submitted a proposal in which they were stating that by investing the additional funds allocated into new testing and diagnostic equipment it is possible to reduce the duration of a maintenance task defined for component A in option 2 by 50%.

Which option should be adopted and why?

Best to the author’s knowledge today there is no maintenance management body of knowledge that is able to provide a quantitative justifiable answer to the above questions. In the remaining part of the paper, it will be shown how to apply MIRCE Science equations to provide the quantitative answer to the question posed, to maximize the return on investment like profit, reputation, loyalty, public benefit, and so forth.

5 MIRCE Science based solution for analysis of maintenance management options #

Option 1:

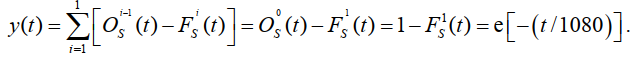

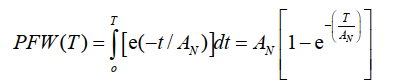

Based on the information available the only possible conclusion regarding the probability distribution of the TNE of component A is that it is fully defined by the exponential distribution, which is uniquely defined by the expected value, which in this case is equal to scale parameter AN= E[TNES,]=1080 Hr. The expected positive functionality work from this design option could be determined by obtaining the numerical solution to Eq. 1.

A generic expression for an exponentially distributed cumulative distribution function of a random variable TNEi is

![]()

Based on the data available, the probability of the first negative functionability event of a system, taking place before of at a given instant of time t is:

In this specific case, where it is decided not to take any action after the occurrence of the first negative functionability event, the MIRCE Functionability Equation is defined as:

Finally, by making use of Eq. 1 it is possible to derive the expression for the expected work done, as follows:

For the planned continuous operation of the functional system during a calendar year, T=24×365= 8760 Hr. Hence, the amount of expected positive functionality work to be done by the design option considered is:

![]()

In summary, a functional system defined with the available data is expected to deliver 1079.68 hours of work during the available 8760 calendar hours.

Option 2:

Following the logic used in the analysis of option 1, in this particular example, the exponential theoretical distribution with the expected value of E[TPEs,]= Ap= 168 Hr, is used to describe the motion of a system through PFS. Thus, according to the data available, the cumulative distribution function for the time of occurrence of ith positive functionality event is defined as: Thus, the MIRCE Functionability Equation (Eq. 2) becomes fully defined by the set of convolution integrals which are of the form of the Gamma probability distribution, as the convoluting functions are defined by the identical exponentially distributed random variables, TNEs,i and TPEs,i in the following way:

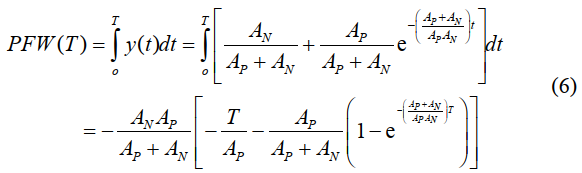

Dubi [1] has proven that a generic expression for the MIRCE Functionability Equation (Eq. 2) for equally exponentially distributed time to negative and positive functionability events, as defined above, is equal to:

The amount of the expected positive work to be done by the system defined by option 2 could be calculated by substituting the function y(t) into Eq. 1, thus:

After substituting the values for the parameters in the above expression the expected positive functionality work will be 7600.34 Hr.

Thus, by designing a system in a way that it is possible to return it in PFS after the occurrence of NFE by performing specific maintenance activities, the expected work done by a system will increase by 6520.66 Hr, in respect to the expected work done by option 1.

Option 3: By implementing proposed changes in design, originated by the reliability engineering team, the expected time to the occurrence of NFE, will increase from 1080 Hr to 1620 Hr, while maintaining the same probability distribution for TPES,i, thus:

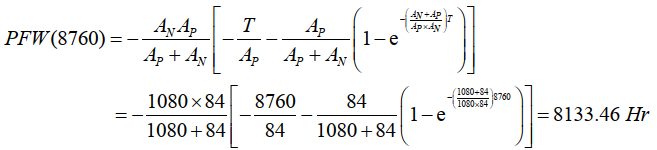

Option 4: As a result of improved testing and diagnostics equipment, proposed by the maintenance engineering department the expected time in NFS will be reduced to Ap=84 Hr, while maintaining the same probability distribution for TNEs,i, hence:

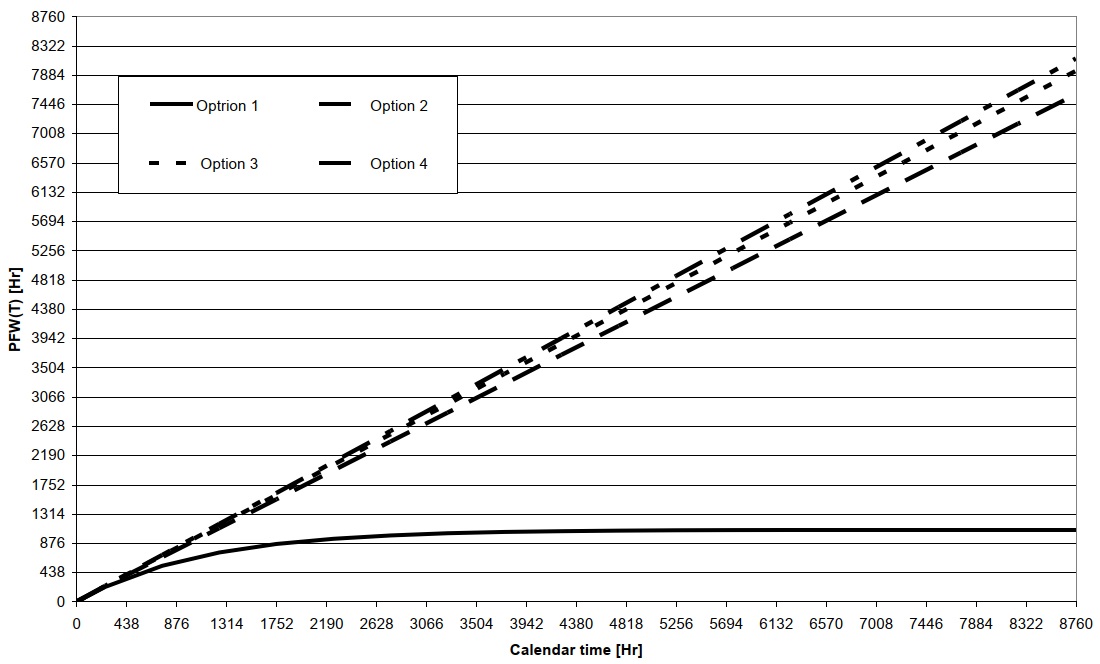

Based on the predicted expected work done by the system under consideration, by applying the MIRCE Science equations the final solution to be recommended for the adoption for the future system is option 4. This feasible maintenance solution provides additional work of 351 Hr in respect to option 3 (improved reliability) and 533 Hr in respect to option 2, as illustrated by Figure 1.

Figure 1: Expected work done by all four feasible maintenance management options

The impact of all feasible solutions presented above on: revenue, cost and profit could be easily computed by making use of the MIRCE Profitability Equation presented in [4].

6 MIRCE Science based physical analysis of maintenance management options #

The mathematical analysis of the four feasible design options, considered above, has shown that is expected that option 4 will provide the highest amount of work done during the year of operation, with the same monetary value of resources invested in design as the other three. This conclusion was made by quantitatively evaluating the MIRCE Functionability Equation for each design option using the available input data.

From a mathematical point of view, the obtained results are correct as none of the mathematical equations violate any mathematical laws. However, as these are engineering design options, it is the duty of design engineers and reliability analysts to select the input data into mathematical predictions. This is primarily related to the selection of mathematical models that define physical mechanisms that generate the

motion of functionable systems through functionability states, as the MIRCE Functionability Equation is presented in a generic form, suitable for any application. However, the specific probability functions have to be selected by the designers of specific systems.

In the above example, exponential probability distributions are selected for random variables, TNEi and TPE, purely for ease of the calculation of corresponding convolution integrals (Eq. 3 and 4).

From a reliability point of view, the mathematical assumption made had the following physical consequences, thus component A cannot:

- experience any manufacturing, transportation, and installation actions that would generate an NFE,

- experience any time or usage-related degradation mechanisms, like corrosion, fatigue, thermal deformation, creep, wear, and similar,

- experience any maintenance or storage-induced action that would generate an NFE

- be exposed to seasonal, operational, or geographical variability.

From a maintenance point of view, the mathematical assumption made had the following physical consequences; no maintenance action applied to the system can have fix duration of time required for its successful completion, like:

- 24 hours for the paint to dry

- 12 hours for a physical/chemical analysis used as a part of the troubleshooting process,

- 7 days contractual provisioning of spare parts

The above statements of reliability and maintenance are a physical reality known and experienced by engineers, managers, technicians, and others involved with the operation process of functional systems. Based on the above analysis of the observable physical reality excluded by mathematical assumptions of exponentially distributed times of the evolution of functionality of a system through MIRCE Space, [5], presented in the numerical example used in this paper, the following two points must be made:

- Equations 1 and 2 are generic expressions applicable to any functional system, operating in any natural environment, and exposed to any human-imposed rules. In order to be utilized during the design process it is necessary that reliability and maintenance professionals are involved to identify mathematical laws that adequately described the physical reality of their systems and then seek a method for evaluation of convolution integrals defined by Eq. 3 and 4.

- Equations 5 and 6 provide accurate predictions of the expected work to be done during the in-service lives of functional systems given that operational and maintenance limitations, some of which are listed above, and many others, are not applicable to their systems, otherwise the predictions would be incorrect.

7 A few words more about the use of MIRCE Functionability Equation #

The numerical example used in this paper is related to a system that consists of a single component, where both positive and negative functionality actions are mathematically

represented by corresponding exponential probability distributions, for a very simple reason. This combination is the only case for which an explicit closed mathematical solution exists.

In view of the fact that realistic systems involve more than a single component with more than one functionality event generating mechanisms the possibility of finding an analytical solution for multidimensional convolution integrals defined by Eq. 3 and 4 is seldom possible due to the inability of mathematics to deal with a large number of convolution functions and their interactions. These types of problems are not specifically related to MIRCE Science, they are common to all scientific disciplines of this nature, as it is a known mathematical fact that integral equations do not have analytical solutions. [1]

The most suitable way forward for any real functional system, of any complexity of operational reality, is to apply the Monte Carlo method as the only viable approach with which solutions for the MIRCE Functionability Equation and thereby for the system performance may be obtained. It is applicable to systems with multiple interacting components, aging mechanisms, and any operation, maintenance, and support rules. Thus, the Monte Carlo method provides the performance function of a system for any given scenario and with any form of resources, but it is beyond the scope of this paper.

8 Conclusions #

The main objective of this paper is to introduce the global maintenance management and engineering community to the body of knowledge contained in MIRCE Science for the innovative approach to maintenance, which is perceived as the management of failures and provision of work. Thus, maintenance manages the consequences of the complex interactions between failure events and maintenance actions are taken that drive the behaviour of functional systems, which can be quantified by the MIRCE Functionability Equation. Hence, in the future maintenance managers will be able to perform quantitative trade-offs between feasible failure management options to determine one that would yield the greatest benefit measured through the expected profit. To illustrate the advantages of applying MIRCE Science to the maintenance management process a numerical example is provided, where several feasible maintenance options are considered and quantified.

To illustrate the advantages of applying MIRCE Science to the reliability engineering decision-making process a numerical example is provided, where the trade-off between reliability improvements by increasing the expected time to failure by 50% or decreasing maintenance time by 50%, is addressed.

The challenges related to the applicability of MIRCE Science to the future maintenance management process, mainly driven by the mathematical inability to analytically deal with multidimensional convolution integrals, are highlighted in the paper and the use of the Monte Carlo method is recommended.

References #

- Dubi A. (2000) Monte Carlo Applications in Systems Engineering, pp. 268, John Wiley & Sons, Chichester, UK, 2000.

- Knezevic, J. (2017) The Origin of MIRCE Science, pp. 232, MIRCE Science, Exeter, UK, 2017, ISBN 978-1-904848-06-6

- Knezevic, J. (2014) MIRCE Functionability Equation, Int. Journal of Engineering Research and Applications, Vol. 4 Issue 8 (Version 7), August 2014, pp 93-100, ISSN: 2248-9622 (open access publication)

- Knezevic J. (2016) MIRCE Profitability Equation, Journal of Mechanical Engineering, pages 115-122, Vol. 13, Num. 2, April-June 2016, University of Zenica,Faculty of Mechanical Engineering, Zenica, Bosnia and Herzegovina, ISSN 1512-5173

- Varde, P.V., Prakash, R.V., Joshi, N.S., Risk-Based Technologies, MIRCE Science Based Operational Risk Assessment, pp. 223-258, Springer Nature Singapore Pte. Ltd., Singapore, 2019.