Mohammed Abdulaziz

Chief Technology Officer at Ressol Energy – Germany, mohammed.abdulaziz@ressolenergy.com Chief Executive Officer at Ressol Energy – Saudi Arabia

Honor Professor at North-Hesse University of Applied Sciences – Germany Honor Professor at BBW University of Applied Sciences – Germany

Abstract #

Dust and hot spots are the most challenging topics facing the maintenance of solar systems including photovoltaic flat panels, concentrated solar power systems, and concentrated photovoltaic systems. This challenge raises especially for the companies providing aftersales services and the contractors providing maintenance guarantees. The cost of such type of maintenance in solar energy contacts is an important number added to the value of energy production. In dusty regions, like Saudi Arabia, this topic is mainly in the solar energy market and categorized in the same importance and priority with high-temperature challenges. The current paper discusses a novel technology owned by the German company Ressol Energy. The discussed technique uses the attraction force between ions to collect the dust on the surface of photovoltaic (PV) solar panels as well as the mirrors attached to the concentrated solar power (CSP) and concentrated photovoltaic (CPV) energy systems. The results show the improvement of energy production.

Keywords: solar, UAV, IoT, digitalization, cleaning, photovoltaic, concentrated photovoltaic, CPV, CSP

Disclaimer

All information and data provided in this document are property of Ressol Energy – Germany and protected by the law. Any copy of the mentioned product or process will lead to a legal process.

The document is therefore allowed to be published as a research paper in the OMAINTEC Conference.

Introduction #

A photovoltaic panel generates electricity from solar radiation. Photovoltaic panels consist of semiconductors, with the help of solar radiation it is converted into direct current. As this technology is pollution-free, renewable, and safe, it has achieved rapid growth in the recent past. Mega solar power plants have already been installed in different countries such as Australia, Middle East, the USA, Europe, and China He et al. [1]. Huge solar power plants are installed in deserts where the sun’s rays are brightest at lower altitudes. On-site problems that are usually overlooked are bird droppings, dust deposition, and water spots, which reduce the efficiency of solar panels drastically. Also, there is a 10-25% reduction in efficiency due to losses in wiring, unit contamination, and inverter [3]. It was analyzed that dust accumulation mainly depends on the slope, direction, type of coating, surface roughness, etc. The factors affecting dust stability are shown in Figure 1. It is reported that the energy loss is large in the fixed horizontal panels, which is about 8-22%, then compared to the inclined panels (45 °C), here the losses are only about 1-8%. Also, other external factors such as humidity, temperature, wind speed, and regional characteristics such as traffic, air pollution, and vegetation play important roles in dust deposition. Moreover, the biological, electrical, and chemical properties of the dust, as well as the shape, size, and weight of the dust particles affect the accumulation of dust on the surface of the panels [4]. A large number of studies have been conducted on the process of dust deposition on PV modules. It is observed that the density of dust accumulation mainly depends on the angle at which the PV module is installed [5]. The penetration of sunlight through the glass cover of the PV module was hindered by dust deposition, which greatly affected the arrival of sunlight to the solar cell [6]. Energy loss due to pollution may vary based

on the physical and chemical properties of dust particles, and it may also vary depending on geographical locations [7]. The process of cleaning the solar cells will produce slurry residue due to sticky dust, cleaning fluids, etc. [8]. With the help of a wind cleaning process, Jiang et al. [9], concluded that the wind speed ranged from 0.82 m/s to 2219.8 m/s and that the ratio of shear speed to wind speed ranged between 0.04 -0.06. They calculated particle diameters ranging from 0.1 m to 100 m. Hussein et al. [10] did a comparative study of seven different types of dust samples on photovoltaic panels under the three different radiation levels such as 650, 750, and 850 W/m2. They note that the smaller particles block the more sunlight.

Figure 1: Factors influencing dust settlements [3]

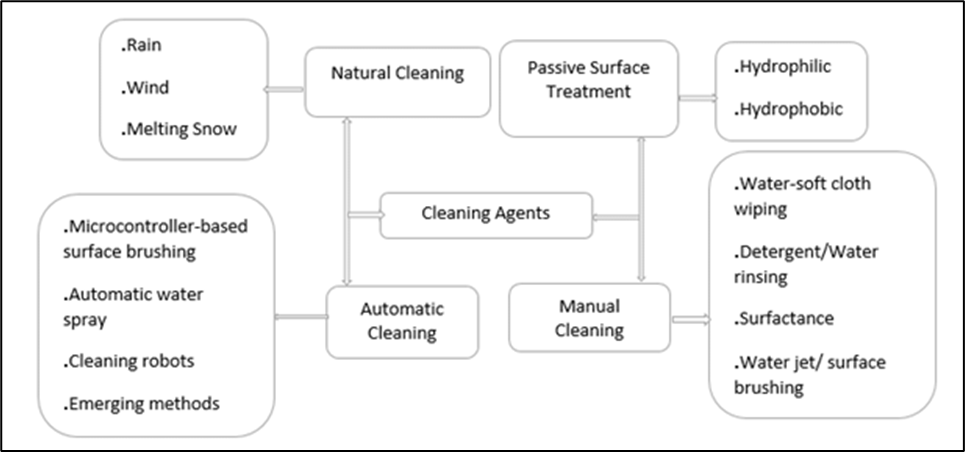

Saidan and others. [11] I recommend that the scheduled cleaning of the solar panels is very important, otherwise, the impact size of dust will be too high. Margaret K. S. and others. [12] Discuss the robot cleaning system where the robot’s control system consists of an Arduino microcontroller. Gayer and others. [13] He experimented to find out the effect of Mars dust particles on photovoltaic cells at varying wind speeds (23 to 116 m/s). The superb hyperbolic shell Polydimethylsiloxane (PDMS)-coated PV solar panels will reduce the efficiency degradation of solar panels by airborne dust [14]. Figure 2 [15] shows different dust removal methods for solar collectors. The dry-cleaning method removes dust particles from the surface, but the wet cleaning method has been observed to be more effective [16].

Figure 2: Different cleaning methods for removing dust from solar collectors [15]

Dust buildup on solar panels affects performance. As a result, it was observed that the performance of the PV panel decreased by up to 85% [17]. Compared with flat-panel PV, the 360° automatic cleaning and solar tracking system generate 30% more energy [18]. Both anionic and cationic surfactants are used to remove dust from solar panels. For the precipitated sand particles, the anionic surfactant is the most effective compared to the cationic surfactant [19]. Spraying water on photovoltaic cells increases the efficiency of the photovoltaic system [20]. Gheitasi et al. [21] He made an experimental setup consisting of a wireless sensor network to collect data on dirt levels from each solar panel. Then the robots clean the dirty plate system with the help of the collected data. Electric blinds can be used with standing waves to remove particles from the surface [22]. Carlson et al. [23] Studied inorganic hyperbolic coatings for self-cleaning surfaces. Chen et al. [24] Invented multifunctional coating with different properties from anti-reflective, ultra-hydrophobic, etc. to solar PV sheet glass cover uses TiO2 / SiO2 compound to reduce dirt accumulation [25]. PV panel tilt angle affects the density of dust deposition. dust deposition density ranges from 15.84 to 4.48 g/m2 [26]. Kao et al discuss the possibilities of anti-freeze coated surfaces that are ultra-waterproof and change surface texture. Jagila et al. [28] With their empirical analysis they calculated an average annual PV efficiency of 8.7% under outdoor conditions in Athens, Greece. To resolve cloud cover over photovoltaic panels Gandoman et al. [29] Suggest a model that has the advantage of supporting cloud cover throughout all seasons. Ganesh et al [30] highlight the peeling effect on self- cleaning surfaces. Due to the regional weather in Brighton in the UK, the effect of dust deposition on the solar PV module was found to be smaller. But the performance was greatly affected by the local problem of bird droppings [31], which would lead to lower efficiency. The performance of nanoscale solar cells decreased with an increase in air mass. They are about 94.18%, 81.86%, and 37.47% for direct, global, and diffuse solar radiation, respectively [32]. John and others. [33] Demonstrated anti-reflective and highly hydrophobic photovoltaic cells with large energy conversion efficiency using highly hydrophobic nanogram glass.

Methodology #

As mentioned, and discussed in the introduction above, there are many technologies used to clean solar panels. On another hand, several factors can influence the accumulation of dust on the solar panels. The same situation can be applied to the CSP and CPV mirrors and lenses.

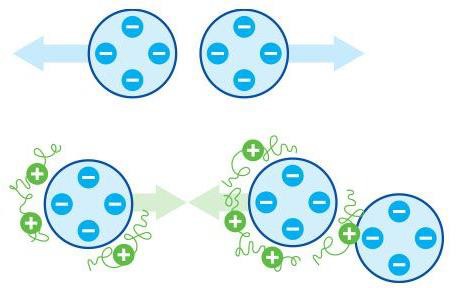

The research and development team of Ressol Energy Global was focused in its research on finding a cost-effective method to remove the dust efficiently. The concept of the current design was built on the physical phenomenon of ions’ attraction force. Figure 3 shows the process, in which the dust particles coagulate to the positive ions to form heavier particles.

Figure 3: dust collecting process

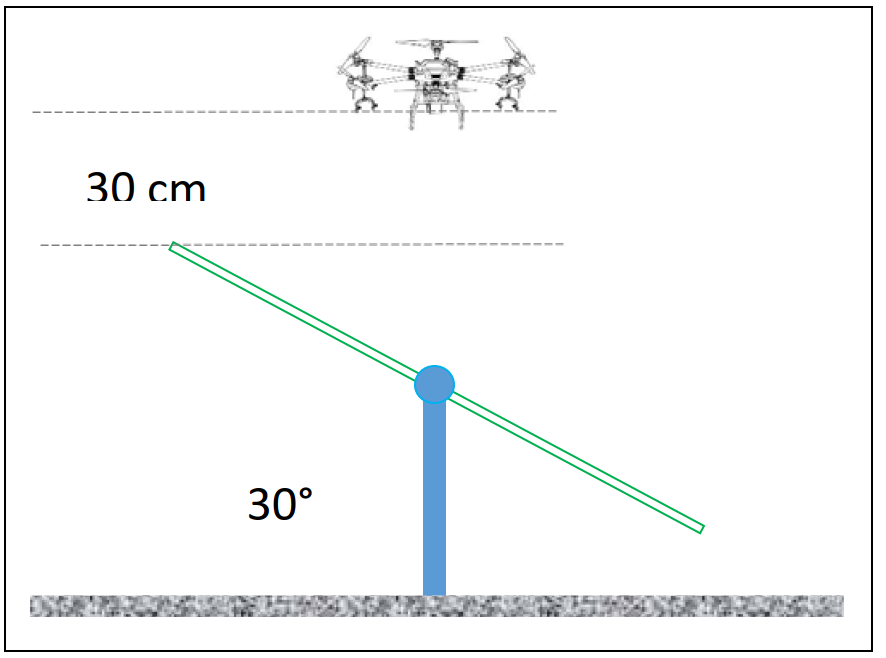

The heavily positive ion content of the fluid solution made by Ressol Energy can force the dust accumulated on the solar panel to be swept into heavier flocs. The positive ions fluid is to be spayed by a big drone using the draft force produced by the rotors. Figure 4 shows the used drone. The injectors could be seen clearly under the propellers, where the double injectors are used.

The drone used in the experiment was produced in cooperation with the drones’ company DJI. The drone can fly 3.8 km without recharging to cover a long range of solar panels at once. Furthermore, it can fly autonomously or remotely controlled. The high technical specification of the drone ensures a highly efficient cleaning process.

In further steps of the cleaning process, the flocs resulted from the physical reaction described above move downward. The motion of flocs is a result of gravity, surface properties, and tilt angle.

Figure 4: the drone used in the spraying process

The experiment was done to measure the effectiveness of the mentioned cleaning method is simple. A flat solar panel was subjected to natural dust covering in aggressive dusty weather conditions in North Africa. The energy production was decreased by 43% compared to the cleaned panel in the same position and under the same solar conditions. The drone flew over the panel at its rated speed and sprayed the fluid at a height of 30 cm of panel upper tip. The following figure 5 shows a side view of the experiment setup. In the following section, the results are shown.

Figure 5: a side view of the experiment setup

Results #

The mentioned experiment was done several times to ensure the correctness of the gathered data. The power production was improved by 52% compared to the power produced before the cleaning process takes place.

Conclusions #

The present paper discussed a novel concept of cleaning technology developed by the research team of the German company Ressol Energy. The research was done in north Africa where the factors affecting the dust accumulation on solar panels are significant. The experiment was done in a repeating process to ensure the precision and accurateness of the readings.

The discussed technology shows an improvement in the production of energy compared to the uncleaned situation by 52%.

Since the product is already offered on market by Ressol Energy Global, the company took this research and development activity as further development over the old version of the technology. That opens doors for further research will be done shortly to bring this technology to the top of performance and to provide a significant research contribution.

References #

- He Gaofa, Zhou Chuande, Li Zelun, Review of Self-Cleaning Method for Solar Cell array, Procedia Engineering, Vol. 16, pp 640-645, 2011

- Kawamoto Hiroyuki, Guo Bing, Improvement of an electrostatic cleaning system for removal of dust from solar panels, Journal of Electrostatics, Vol. 91, pp 28-33, 2018.

- Mani Monto, Pillai Rohit, Impact of dust on solar photovoltaic (PV) performance: Research status, challenges, and recommendations, Renewable and Sustainable Energy Reviews, Vol.14, pp 31243131, 2010.

- Arabatzis Ioannis, Todorova Nadia, Fasaki Ioanna, Tsesmeli Chrysovalanti, Peppas Antonis, Li Wen Xin, Zhao Zhiwei, Photocatalytic, self-cleaning, anti-reflective coating for photovoltaic panels: Characterization and monitoring in real conditions, Solar Energy, Vol. 159, pp 251- 259, 2018.

- Jiang Yu, Lu Lin, Lu Hao, A novel model to estimate the cleaning frequency for dirty solar photovoltaic (PV) modules in desert environment, Solar Energy, Vol. 140, pp 236-240, 2016.

- Syafiq A, Pandey A. K, Adzman N. N, Rahim Nasrudin Abd, Advances in approaches and methods for self-cleaning of solar photovoltaic panels, Solar Energy, Vol. 162, pp 597-619, 2018.

- Chen Eugene Yu-Ta, Ma Lian, Yue Yuan, Guo Bing, Liang Hang, Measurement of dust sweeping force for cleaning solar panels, Solar Energy Materials and Solar Cells, Article in press. 13 International Journal of Pure and Applied Mathematics Special Issue [8]

- Zhen-Yu Hou, et al., Research Of Control System Based On Solar Panel Cleaning Mechanism, International Journal of Research in Engineering and Science (IJRES), Vol. 4, Issue 5, pp 01-05, May 2016.

- Jianga Yu, Lu Lin, Ferro Andrea R., Ahamadi Goodarz, Analyzing wind cleaning process on the accumulated dust on solar photovoltaic (PV) modules on flat surfaces, Solar Energy , Article in press

- Hussain Athar, Batra Ankit, Pachauri Rupendra, An experimental study on effect of dust on power loss in solar photovoltaic module, Renewables, 4:9, 2017.

- Saidan Motasem, Albaali Abdul Ghani, Alasis Emil, Kaldellis John K., Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment, Renewable Energy, Vol. 92, pp 499-505, 2016.

- Margaret K. S, Bathirnath T., Kumar Dinesh V., Kumar Praveen N., Automatic Solar Panel Cleaning Robot, International Journal of Emerging Research in Management Technology, Vol.6, Issue-7, pp 251-255, 2017.

- Gaier James R., Perez-Davis Marala E, Effect of Particle Size of Martian Dust on the Degradation of Photovoltaic Cell Performance, International Solar Energy Conference, Hawaii, April 4-8, 1992.

- Park Yong-Bum, Im Hwon, Im Maesoon, Choi Yang-Kyu, Selfcleaning effect of highly water- repellent microshell structures for solar cell applications, Journal of Materials Chemistry, Vol. 21, pp 633-636, 2011.

- Aidara Mohamed Cherif, Ndiyae Mamadou Lamine, Mbaye Amy, Sylla Mamadou, Ndiaye Pape Alioune, Ndiaye Amadou, Study of the Performance of a system for dry cleaning dust deposited on the surface of solar photovoltaic panels, International Journal of Physical Sciences, Vol. 13(2), pp 16- 23, 2018. 14 International Journal of Pure and Applied Mathematics Special Issue

- Kiran M. R, Padaki Rekha G, Self-cleaning Technology for Solar PV panels, International Journal of Scientific Development and Research, Vol. 1, Issue 9, pp 148-173, 2016.

- Sulaiman Shaharin Anwar, Singh Atul Kumar, Mokhtar Mior Maarof Mior, Bou-Rabee Mohammed A., Influence of Dirt Accumulation on Performance of PV Panels, Energy Procedia, Vol. 50, pp 50 56, 2014.

- Tejwani Ravi, Solanki Chetan S., 360◦ Sun tracking with automated cleaning system for solar pv modules, IEEE, pp 2895-2898, 2010.

- Abd-Elhady M. S., Zayed S. I. M., Rindt C .C. M., Removal of dust particles from the surface of solar cells and solar collectors using surfactants, Proceedings of International Conference on heat Exchanger-Fouling and cleaning, Greece, pp 342-348, June 5-10, 2011.

- Adolzadeh M., Ameri M., Improving the effectiveness of a photovoltaic water pumping system by spraying water over the front of photovoltaic cells, Renewable Energy Vol.34, pp 91-96, 2009.

- Gheitasi Alireza, Almaliky Ali, Albaqawi Nawaf, Development of an atomic cleaning system for photovoltaic plants, IEEE PES Asia-Pacific Power and Engineering Conference (APPEEC), 2015.

- Atten Pierre, Pang Hai Long, Reboud Jean-Luc, Study of Dust Removal by Standing-Wave Electric Curtain for Application to Solar Cells on Mars, IEEE Transactions on Industry Applications, Vol. 45, No. 1, pp 75-86, Jan/Feb 2009.

- Carlson William Brenden, Sjong Angele, Wan Feng, Londergan Timothy, Inorganic Hydrophilic Self-cleaning coatings, Google patents, Feb, 2014 .

- Chen Junjun, Zhang Lin, Zeng Zhixiang, et al., Facile fabrication of antifogging, antireflective, and selfcleaningtransparent silica thin coatings, Colloids and Surfaces 15 International Journal of Pure and Applied Mathematics Special Issue A: Physicochemical and Engineering Aspects, Vol. 509, pp 149157, 2016.

- Jesus Magnug Augusto Moraes Lopes de, Neto Joao Trajano Da Silva, Timo Gianluca, et al., Superhydrophilic self-cleaning surfaces based on TiO2 and TiO2/SiO2 composite films for photovoltaic module cover glass, Applied Adhesion Science, 3:5, 2015.

- Elminir Hamdy K., Ghitas Ahmed E., et al., Effect of dust on the transparent cover of solar collectors, Energy conversion and management, Vol. 47, pp 3192-3203, 2006.

- Cao Liangliang, Jones Andrew K., Sikka K. Vinod, Wu Jainzhong, Gao Di, Anti-Icing Superhydrophobic Coatings, American Chemical Society, Langmuir Letter, Vol. 25(21), pp 12444-12448, 2009.

- Gaglia Athina G, Lykoudis Spyros, Argiriou Athanassios A., Balaras Constantinos A., Dialynas Evangelos, Energy efficiency of PV panels under real outdoor conditions – An experimental assessment in Athens, Greece, Renewable Energy, Vol. 101, pp 236-243, 2017.

- Gandoman Foad H, Raeisi Fatima, Ahmadi Abdollah, A literature review on estimating of PV- array hourly power under cloudy weather conditions, Renewable and Sustainable Energy Reviews, Vol.63, pp 579-592, 2016.

- Ganesh V. Anand, Raut Hemant Kumar, Nair A. Sreekumaran, Ramakrishna Seeram, A review on Self-Cleaning coatings, Journal of Materials Chemistry, Vol. 21, pp 16304- 16322, 2011.

- Ghazi Sanaz, Ip Kenneth, The effect of weather conditions on the efficiency of PV panels in the southeast of UK, Renewal Energy, Vol. 69, pp 50-59, 2014.

- Guechi A., Cheegar M., Aillerie M., Environmental effects on the performance of nanocrystalline silicon solar cells, Energy Procedia, Vol.18, pp 1611-1623, 2012. 16 International Journal of Pure and Applied Mathematics Special Issue

- Gwon Hyo Jin, et al. Superhydrophobic and antireflective nanograss-coated glass for high performance solar cells, Nano Research, Vol. 7(5), pp 670-678, 2014.