GENERATION OF SOLUTIONS CATALOG FOR EARLY-STAGE ASSET LIFECYCLE DECISION MAKING

Adolfo Crespo del Castillo2, Adolfo Crespo Márquez1, Diego Pérez Oliver1, José Antonio Marcos3

1 Department of Industrial Management, School of Engineering, University of Seville, Spain

2 Ingeman, Association for the Development of Maintenance Engineering, School of Engineering Seville, Spain

3Patentes Talgo, Smart Maintenance Systems Department, Alcobendas, Madrid, Spain

Abstract #

This paper highlights the importance of digital transformation for asset management when applied across every stage of the asset lifecycle. To achieve this, a thorough assessment of the entire asset lifecycle is essential, emphasizing the identification of key indicators that furnish valuable data for decision-making at each stage. Most of digital IAMS (Intelligent Asset Management Solutions) are focused on the O&M (operations and maintenance) stage of assets lifecycle, however, in this paper we propose a solution in the early stages of the lifecycle, that could be use either for manufacturers or asset buyers/owners. In this study, we present a solution for analysing asset needs and their future operations and maintenance plans with the aim of guiding asset acquisition decision-making based on maintenance service, type of operation, and fleet of assets size. The proposed approach utilizes discrete event simulation to predict the levels of availability for a fleet of assets under a specific demand and maintenance service type. This type of solutions guides the path to servitise not only O&M, but earlier stages of assets lifecycle, and clarify the interaction between companies that acquire valuable assets and the asset’s manufacturers by defining the needs and helping to balance the capital and operational investments.

Keywords: Asset lifecycle management, Asset strategy, Asset Acquisition, Maintenance Servitisation, Discrete Event Simulation

1. Introduction #

The evolution of asset lifecycle management in the context of digital transformation has become a crucial focus for businesses enabled by incorporating data from numerous sources and intelligent tools for a more informed decision-making (McKinsey & Company, 2022). In particular, the early stages of asset lifecycle management require meticulous planning aligned with specific business needs, in order to acquire, operate and maintain the optimal quantity of assets and services to achieve these business needs (Crespo Márquez, 2022; The institute of Asset Management, 2016) . However, a notable challenge lies in the lack of comprehensive mathematical tools to optimize the planning of asset and services needs to either acquire or sell valuable assets (Macchi et al., 2018). This paper addresses this gap by proposing a novel tool for asset and services acquisition, integrating intelligent features that facilitate strategic maintenance planning based on services and capabilities. The proposed tool not only fills the void in mathematical optimization tools for early asset lifecycle stages but also introduces a dynamic aspect, allowing businesses to align their asset planning with evolving service and capability requirements. Furthermore, this tool serves as a valuable resource for OEMs that not only sell their manufactured assets but also the maintenance services associated to the asset operations and maintenance lifecycle stage (Gaiardelli et al., 2021; Sala et al., 2022). This approach does not only streamline the planning process but also shapes the offer that OEMs can leverage to sell their products, thereby contributing to a more integrated and efficient approach to asset lifecycle management and allowing to servitise the assets maintenance offering multiple maintenance services associated to the manufactured product (Martinez et al., 2018; Pirola et al., 2022). On the other hand, large asset owners, particularly in sectors such as transportation or oil and gas, could derive benefits from this approach by strategically planning their asset acquisition in alignment with business needs. This entails deciding whether it is more advantageous to acquire a specific number of assets with a corresponding number of services and how to strike a balance between asset and service acquisition.

The objective of the paper is to introduce a tool designed to optimise decision-making in the early stages of the lifecycle and highlight the benefits that this solution offers to either OEMs or asset owners. Additionally, the paper reflects on the transformation of asset lifecycle management decision-making due to digitalisation. To achieve this, the paper begins by presenting the research background in section 2. Subsequently, section 3 outlines the proposed approach, applied to a case involving an asset fleet in collaboration with Talgo, a Spanish rolling stock OEM, and maintenance service experts. The results are then presented in section 4 to illustrate the benefits, and section 5 provides a concluding discussion reflecting on the solution approach.

2. The improvement of asset lifecycle decision-making through digitalisation #

Effectively overseeing the complete lifecycle of assets is crucial for businesses making substantial investments, dedicating significant resources, facing performance dependencies, or dealing with risks related to asset creation, acquisition, utilization, maintenance, or disposal (The institute of Asset Management, 2016). This imperative extends to organizations managing or planning to manage a substantial portfolio of assets, where the optimal performance of asset systems and effective asset management are central to delivering services, products, or achieving broader business objectives (Zhao et al., 2022).

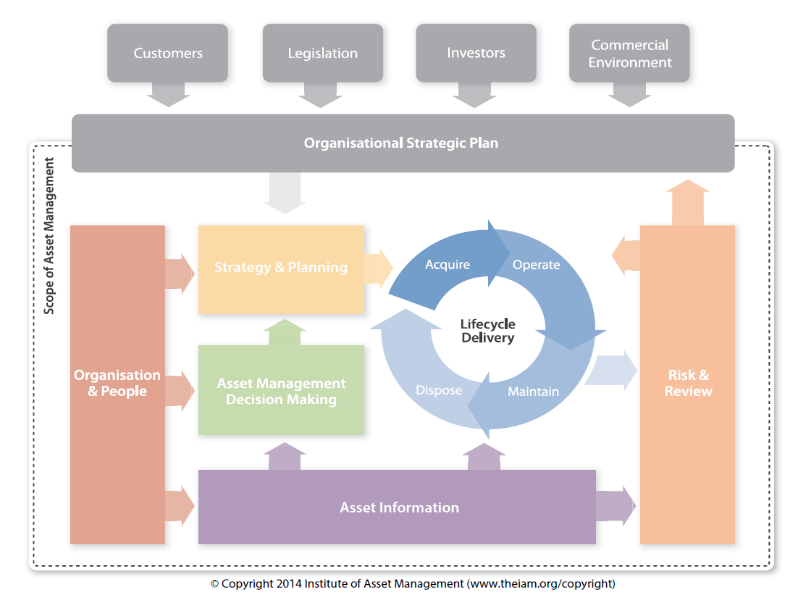

Figure 1: Asset lifecycle representation in relationship with other business dimensions (The institute of Asset Management, 2016)

Consequently, in order to optimise the value generated, the assets that are going to be acquired, operated, maintained, and disposed, have to be aligned with business strategy and needs (Figure 1), and be regulated to fulfil their function in the best manner. Thanks to digital transformation this process has become more integrated and connected, with digital solutions for each stage. However, while there are multiple solutions for operations and maintenance optimisation for either fleets or portfolios (Negri et al., 2021; Petchrompo et al., 2022), and for asset investment planning and disposal (entire lifecycle) (Crespo Del Castillo et al., 2023; Crespo Márquez et al., 2021) there is a clear gap in the planning and acquisition of assets that represents a capital connection between business strategic plan and asset management as it can be seen in the specific subject guidance of the IAM in Figure 1. The absence of solutions derives from the complexity associated with simulating or planning the maintenance and operation conditions under which assets will operate. This complexity further involves considerations of expected resources and maintenance capabilities. Consequently, the acquisition of assets by asset owners is not optimized based on potential maintenance and operation configurations. Moreover, OEMs typically offer their products and services in standardised forms rather than as customised solutions that could be designed and optimized for each individual client (Gaiardelli et al., 2021; Macchi et al., 2018; Martinez et al., 2018). Finally, an essential part of the aforementioned complexity to generate tools at the early stage of assets lifecycle, is the balance of multiple objectives to define the best solution (Erguido et al., 2022).

3. Design of a digital tool for asset requirements planning and acquisition #

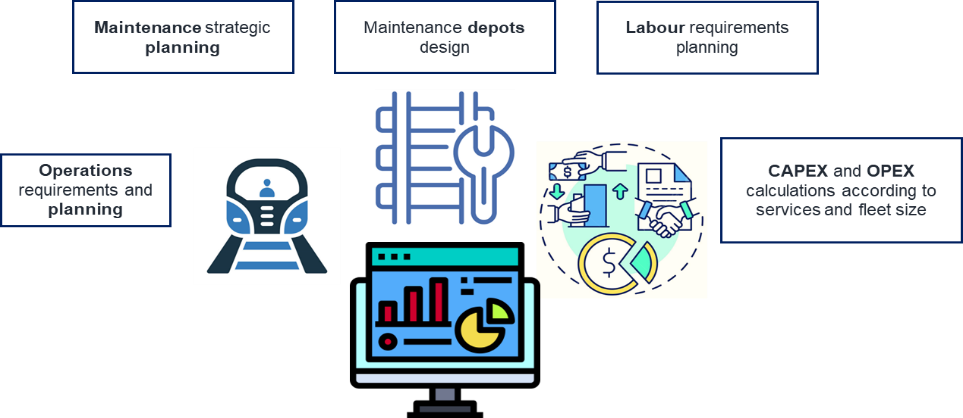

In this section we present a novel tool to support decision-making in the planning and acquisition phase of assets lifecycle. It could be either applied to portfolios of assets, infrastructure, or fleets of transportation assets. In the present case, we apply the solution to a fleet of trains together with the Spanish rolling stock OEM Talgo. We apply the tool to this case as a proof of concept because determining the operation and maintenance conditions of moving assets is more challenging to parameterize and calculate. The tool combines multiple dimensions that constitute the correct quantification of the assets needed, and their subsequent maintenance service, to fulfil certain operational requirements, and with certain maintenance resources limitations. In Figure 2 the solution can be observed, as a modular combination of diverse aspects.

Figure 2: General view of the digital asset plan and acquisition tool

Following the structure in Figure 2, the tool comprises several dimensions with a wide range of input variation, making it highly configurable and suitable for several distinct assets. Following, we provide some insights about these inputs and clarify them by using relevant examples.

Operations requirements and planning: The first dimension to consider, is the operations service plan that the assets have to fulfil. This plan is provided based on the business objectives and corporate strategy. At this stage we consider some data such as the number of assets that will be acquired in the different scenarios to be analysed and the expected usage of these assets. For example, if a company is considering the acquisition of a new fleet of trains, the fleet size and the expected kilometres to be done in a certain planning horizon would be an input. It could also be specified an instantaneous or progressive acquisition and implementation of the assets (something relevant in critical infrastructure or highly variable demands). Additionally, the tool offers a coefficient to generate a non-equal distribution of the usage along the assets.

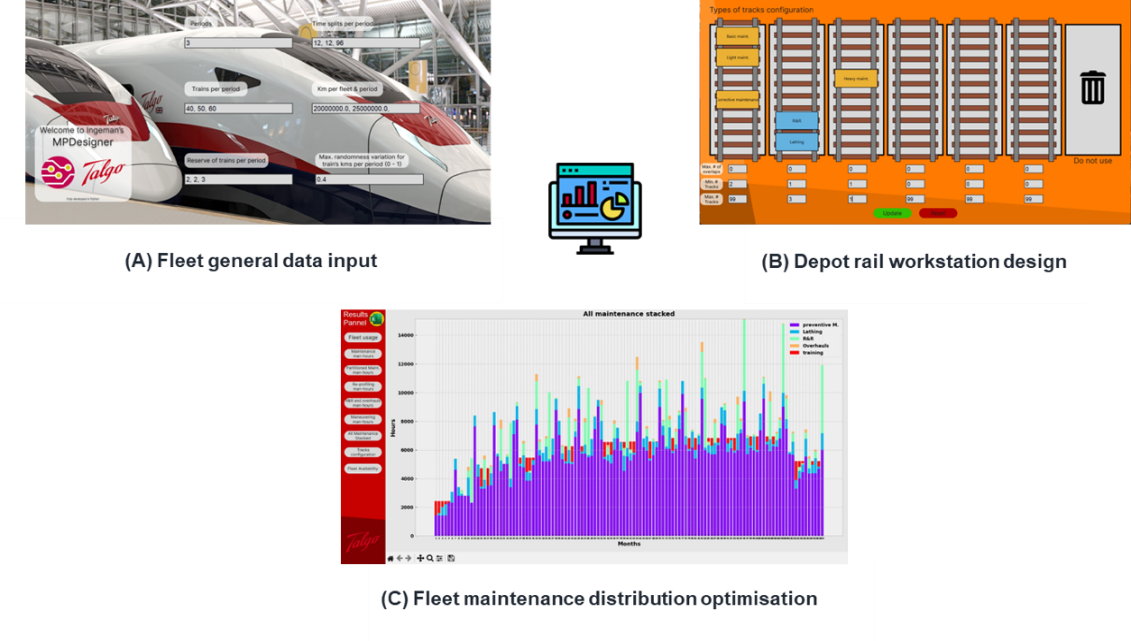

Maintenance strategic planning: The second dimension to consider, that is highly related to operations, is the strategic maintenance plan designed to satisfy operation requirements. This plan could vary being more or less flexible and with more or less stoppages depending on multiple factors such as fleet size, operational requirements, depot availability, and maintenance resources (Figure 3.A). The maintenance plan defines the type of asset inspections and stoppages, the activities to be done in each, and the expected duration for preventive maintenance, plus an expected percentage of corrective maintenance. To stablish the maintenance strategic plan, the tool requires different inputs. These are primarily the man-hours, setup times and hours that are required to perform the activities that are performed in each maintenance stop. Additionally, you can categorize activities, considering that interventions may be conducted in different workstations and/or require different equipment, and specify the available working capacity. It is worth mentioning that due to the correlation between hours and man-hours, a certain amount of time can be enforced for which the asset will be unavailable. For example, this commitment could be to a maximum time for completing the operation, and personnel can be calculated accordingly. Alternatively, the unavailability duration can be defined when the operation is scheduled, taking into consideration the available personnel. Besides, the solution allows to design optimised maintenance plans distributing the time and activities of the different maintenance stoppages in the depots. An interesting option is considering that a certain type of inspection might be partitioned along the usage of the asset rather than fully performed at once. Although this might imply a loss of efficiency due to setup times, the general availability of the asset could greatly improve. For example, some assets are maintained at not-working hours, therefore the asset is not expected to be available at that time and we will not incur on any penalties while carrying out maintenance activities on the asset. Partitioning the activity will result in the possibility of incurring in lower activity times per partition, giving a better chance to only work in the non-penalising intervals. These partitions of maintenance services and interventions have been done based on Talgo maintenance plans, considering the hours and activities that could be decomposed to distributing them in time packages. The calculation of these maintenance partitions is calculated using a genetic algorithm based optimiser considering the rest of inputs previously mentioned. The optimisation is performed by using a Multiple-Population Parallel Genetic Algorithm (also known as Parallel Genetic Algorithm with Islands model) (Cantú-Paz, 1998; Linder & Sekaj, 2011). In this case, the target function is minimising the variation of the workload at each maintenance stop, along all stops in a cycle.

Maintenance depots design: The maintenance plan defines a certain type of maintenance activities to be done, and then depending on the number of depots considered, a calculation will be performed to suggest a number of workstations types and the activities that could be done in each type of workstation. In the case of trains for example (Figure 3.B) each depot has a certain number of rails designed with the machinery and tools installed to carry out certain types of maintenance activities. This design is significant for maintenance execution and cost, as the machinery required for specific critical activities could be really expensive, hence not all rails would have all capabilities (Figure 3.B).

Labour requirements planning: When calculating the availability of the assets given the specified resources and preventive maintenance plan, we potentially incur in a queue problem. This queue problem requires the amount of time that the asset is expected to be available and the available working hours to perform maintenance activities, no matter whether these hours would incur or not in a penalisation due to unavailability.

CAPEX and OPEX calculations according to services and fleet size: Finally, the user of the strategic digital tool has to provide magnitudes associated to the cost (capital investment) that the assets imply, and the costs associated to different maintenance plans configurations. A service with extended stoppages in depots typically comes at a lower cost but demands a larger number of assets to ensure a specific level of availability. On the other hand, a maintenance plan with greater flexibility, involving shorter inspection and depot time, results in a higher service cost but could achieve the same level of availability with fewer assets.

Figure 3: Different views and outputs of the digital tool presented

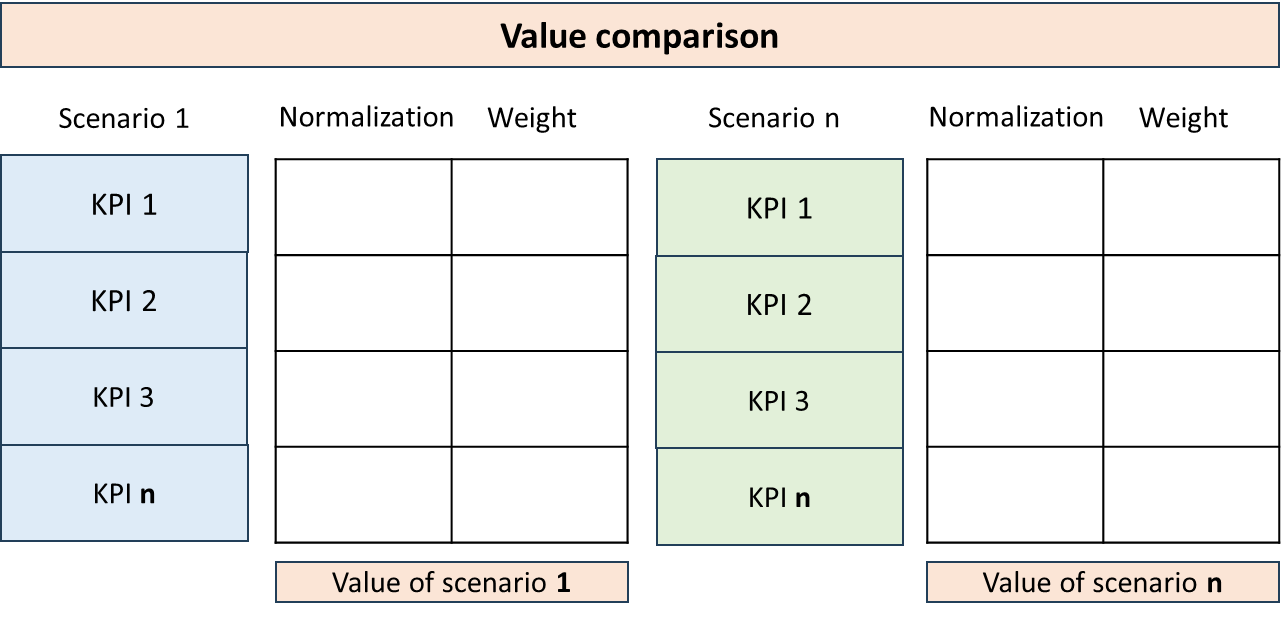

Outputs: When the data is inputted through the GUI, it is processed by the calculating functions in Python 3, using the discrete – event simulation package SimPy. The results are later shown in an interactive dashboard (Figure 3.C), where the workload can be displayed by different aggregations (like all together or by specialties, for example) as well as a matrix with the expected % of availability of each asset at each period of time. Additionally, a report can be automatically generated in a .xlsx file. The solutions are calculated for a certain fleet size with a CAPEX and OPEX associated, and calculating certain KPIs as fleet availability, maintenance depot utilisation, or type of maintenance service. The model is executed with different scenarios to compare the expenditures and KPIs and analyse which has the wider Value for the client according to how it is defined by the company (The institute of Asset Management, 2016), then the scenarios that add more value could be selected or ranked for the purpose.

Figure 4: Scenario KPIs and value comparison

4. Concluding discussion #

In this paper we present a digital solution that transforms early asset lifecycle stages to a more informed decision-making process. In the first section we introduce the background and context that motivate the creation of this solution. Following, in the second section we present a brief analysis of the state of the art of digital tools applied to different stages of asset lifecycle, in order to maximise the value. In this section we underline the lack of solutions in the planning and acquiring stages of assets, in order to optimise asset buying or selling process depending on the situation of the business in the market. Based on the findings, we present the developed tool for optimising strategic planning of operations, maintenance services and resources, and fleet size, in order to satisfy business needs structuring CAPEX and OPEX, in the way that id adds more value.

The digital tool developed show a multitude of robust features that hat position it as a significant advancement in the domain. One of its key strengths lies in its ability to offer parametrised solutions, leveraging a profound understanding of the market to deliver tailored propositions, that have a certain value for the business according to certain KPIs that are measured. The tool facilitates the exploration of diverse maintenance configurations and services, providing users the flexibility to meet demand with varying numbers of assets fleet and different maintenance options. Furthermore, it empowers OEMs to embrace servitisation, enabling them to venture into new markets and expand their offerings through a comprehensive catalogue. A notable advantage for buyers is the tool’s capacity to allow them to configure their investments, striking a balance between a substantial initial investment in assets with a corresponding maintenance service or opting for a more flexible service spread across years with lower initial asset costs. This strategic flexibility not only enhances the adaptability of services but also accelerates the amortisation of initial investments, demonstrating the tool’s prowess in optimizing both operational and financial aspects of business ventures.

6. References #

- Cantú-Paz, E. (1998). A Survey of Parallel Genetic Algorithms. Calcul. Paralleles Reseaux Syst. Repart., 10(2), 141–171.

- Crespo Del Castillo, A., Sasidharan, M., Nentwich, C., Merino, J., & Kumar Parlikad, A. (2023). Data-Driven Asset Health Index–an application to evaluate Quay Cranes in container ports. Maritime Policy and Management, 00(00), 1–19. https://doi.org/10.1080/03088839.2023.2231449

- Crespo Márquez, A. (2022). Digital Maintenance Management. Springer US.

- Crespo Márquez, A., Serra Parajes, J., de la Fuente Carmona, A., & Sola Rosique, A. (2021). Integrating complex asset health modelling techniques with continuous time simulation modelling: A practical tool for maintenance and capital investments analysis. Computers in Industry, 133. https://doi.org/10.1016/j.compind.2021.103507

- Erguido, A., Marquez, A. C., Castellano, E., Parlikad, A. K., & Izquierdo, J. (2022). Asset Management Framework and Tools for Facing Challenges in the Adoption of Product-Service Systems. IEEE Transactions on Engineering Management, 69(6), 2693–2706. https://doi.org/10.1109/TEM.2019.2951438

- Gaiardelli, P., Pezzotta, G., Rondini, A., Romero, D., Jarrahi, F., Bertoni, M., Wiesner, S., Wuest, T., Larsson, T., Zaki, M., Jussen, P., Boucher, X., Bigdeli, A. Z., & Cavalieri, S. (2021). Product-service systems evolution in the era of Industry 4.0. In Service Business (Vol. 15, Issue 1). Springer Berlin Heidelberg. https://doi.org/10.1007/s11628-021-00438-9

- Linder, M., & Sekaj, I. (2011). Parallel genetic algorithms. Mendel, 53(4), 9–15. https://doi.org/10.1145/3400031

- Macchi, M., Roda, I., Negri, E., & Fumagalli, L. (2018). Exploring the role of Digital Twin for Asset Lifecycle Management. IFAC-PapersOnLine, 51(11), 790–795. https://doi.org/10.1016/j.ifacol.2018.08.415

- Martinez, V., Ouyang, A., Neely, A., Burstall, C., & Bisessar, D. (2018). Service business model innovation : the digital twin technology. Cambridge Service Alliance:, November, 1.

- McKinsey & Company. (2022). Capturing the true value of Industry 4 . 0. McKinsey & Company, April, 1–8. https://www.mckinsey.com/business-functions/operations/our-insights/capturing-the-true-value-of-industry-four-point-zero

- Negri, E., Pandhare, V., Cattaneo, L., Singh, J., Macchi, M., & Lee, J. (2021). Field-synchronized Digital Twin framework for production scheduling with uncertainty. Journal of Intelligent Manufacturing, 32(4), 1207–1228. https://doi.org/10.1007/s10845-020-01685-9

- Petchrompo, S., Wannakrairot, A., & Parlikad, A. K. (2022). Pruning Pareto optimal solutions for multi-objective portfolio asset management. European Journal of Operational Research, 297(1), 203–220. https://doi.org/10.1016/j.ejor.2021.04.053

- Pirola, F., Pezzotta, G., Amlashi, D. M., & Cavalieri, S. (2022). Design and Engineering of Product-Service Systems (PSS): The SEEM Methodology and Modeling Toolkit. Domain-Specific Conceptual Modeling: Concepts, Methods and ADOxx Tools, Kowalkowski 2016, 385–407. https://doi.org/10.1007/978-3-030-93547-4_17

- Sala, R., Pirola, F., Pezzotta, G., & Cavalieri, S. (2022). Data-Driven Decision Making in Maintenance Service Delivery Process: A Case Study. Applied Sciences (Switzerland), 12(15). https://doi.org/10.3390/app12157395

- The institute of Asset Management. (2016). Risk Assessment and Management. IAM, V1-361-V1-380. https://doi.org/www.theIAM.org

- Zhao, X., Liang, Z., Parlikad, A. K., & Xie, M. (2022). Performance-oriented risk evaluation and maintenance for multi-asset systems: A Bayesian perspective. IISE Transactions, 54(3), 251–270. https://doi.org/10.1080/24725854.2020.1869871