(CASE STUDY)

Dr. Eng. Mohsen Alamir Alkady

Misr Foundation for Science and Technology Research, Egypt

Abstract #

Today, the drive in industries is to focus on reducing production and maintenance cost while increasing customer satisfaction. One key to succeed with these goals is to develop and improve both quality and maintenance in every phases of any industry processes.

As water industry is the most industry need to be safe and sustainable.

So, there is a need to revolutionize the water industry with the current paradigm shift in technology to better monitoring and control capabilities.

Hence, there is a need for it situ, smart system for on-line monitoring the complex water treatment processes.

The digitalization of water sector is of utmost importance for improving the efficiency and sustainability of managed system. The digitalization process, however, can be seen as a ladder with several steps that the water utility must climb to become a smart utility, the reality is that may water utilities have not completely realized yet the benefits of digital transformation.

The fourth revolution industry (industry 4) has been implemented in multiple engineering field. Such as provisioning of smart monitoring and control capabilities to water supply system (Water 4)

So, water (4) provides an opportunity to identify a promising approach to addressing future management in water supply network. It incorporates the primary features of (industry 4).

Such as digitization and automated sensors (for pressure, flow, and temperature measurement) and model application such as (hydrolic model of water network) opportunity may be created to better understanding water management problems in terms of their complexity and illustrate the use of water 4 in production, early warning and for the decision making process that tends to sustainability in providing clean water.

Keywords: Digitalization, Water 4. Sustainability.

1. Introduction: #

Water is an important component of economies today and is needed in nearly all modes of production. It is a fundamental resource utilized in virtually every modern industrial process and provides an essential element for the development across any country.

The water supply systems are complex and dynamic in nature, and as a result can be considered complex to manage owing to enhanced urbanization level, climate change, growing and varying consumer demands, and limited water resources.

The operation and maintenance of such a system must be managed effecting for sustainable water supply to satisfy the growing consumer demand this creates a need for intelligent systems for the purpose of operational and maintenance management.

In recent years computing technologies have been applied to water systems to assist water utilities in addressing some of these problems.

With the increasing of growth in technology, the water sector is moving to the full phase of digitalization to enhance the sustainability of systems.

Thus, a new industrial revolution in water complex (WATER 4.0) is being researched.

2. Moving from industrial revolution (Industry 4.0) … To, Water system revolution (water 4.0) #

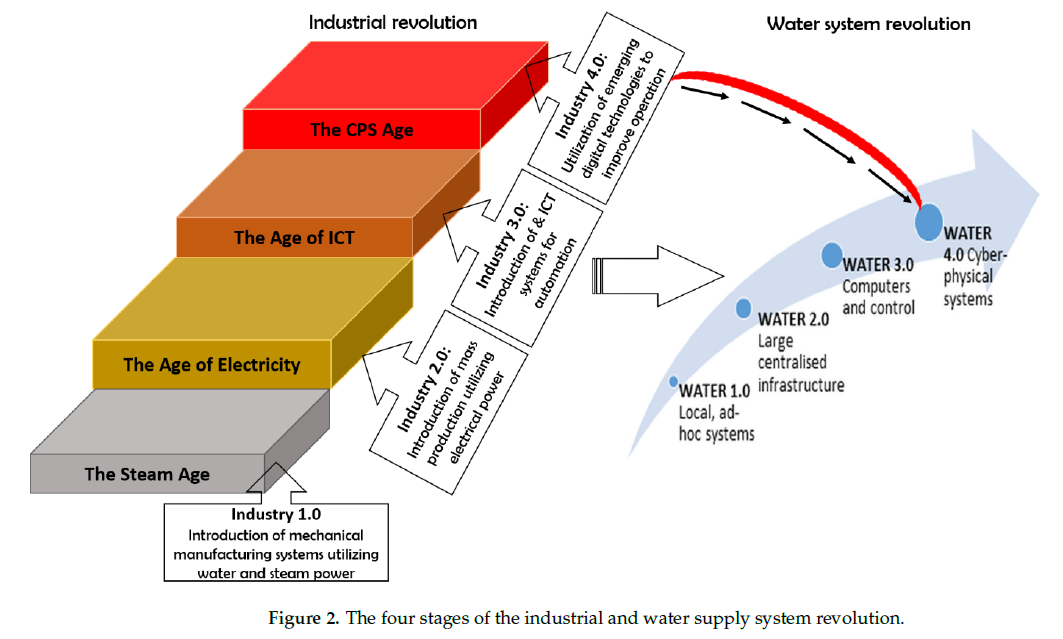

Industry 4.0 is the fourth industrial revolution developed to meet multiple demand of additive manufacturing processes and has been implemented in multiple engineering field such as provisioning of smart monitoring and control capabilities to water supply system.

Water 4.0 provides a unique opportunity to identify a promising approach to addressing future management in water supply networks.

It incorporates the primary features of (Industry 4.0) such as digitization and automation to achieve a systemic water management context. Through the use of automation and increased integration of sensors (for pressure, flow, and temperature measurement) and model applications such as (the hydrolic model of water networks), opportunity may be created to better understanding water management problems in terms of their complexity and to illustrate the use of water 4.0 in production, early warning and for the decision making process.

Figure 1. below show the four stages of the industrial and water supply system revolution.

Figure 1. The four stages of the industrial and water supply system revolution.

Managing and monitoring water supply networks has been a serious challenge facing water utilities. In the past, monitoring and control capabilities in the water supply are provided with supervisory control and data acquision system (SCADA).

However, due to the dynamism, uncertainties and complexity involved in water supply system operations, there is a need to revolutionize the water industry with the current paradigm shift in technology to better monitoring and control capabilities.

Hence, there is a need for in situ, smart system for on-line monitoring of the complex water distribution piping networks.

The new industrial revolution termed (industry 4.0) allows the use of emerging technologies with better monitoring and control capabilities, and better computational and decision support systems to optimize the operation of water supply systems.

This integrating SCADA with network simulation model and control and management of the complex water system.

Such an integrated system from the foundation of water 4.0 for the provision of a real-time SMART WATER network decision support system.

3. Digital Technologies in the Water System: Key Drivers of Water 4.0 #

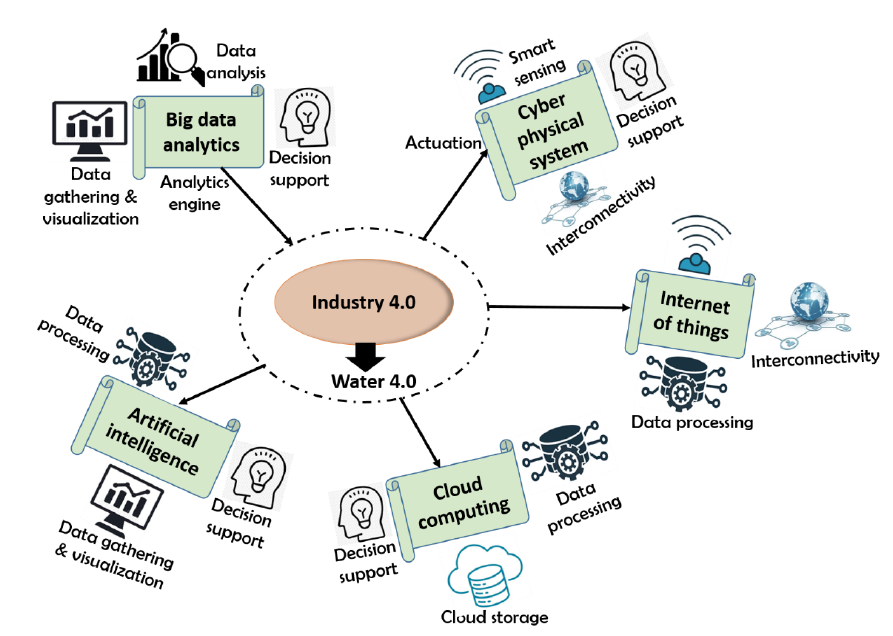

Through the Internet of Thing (IoT) and Cyber Physical System (CPS) the world of manufacturing and network connectivity are incorporated to make industry 4.0 a reality.[1]

The emerging digital technology used this concept are shown in figure 2 below.

Figure 2. Emerging digital technology using IoT and CPS

CPS is the basis of Industry 4.0. [2-4] CPSs, are a fusion of networks, computation, and physical environment in which embedded computing devices.

Continuously sense, monitor and control the physical environment. [5]

CPS represents one of the most important accomplishments in the development of ICT. [6]

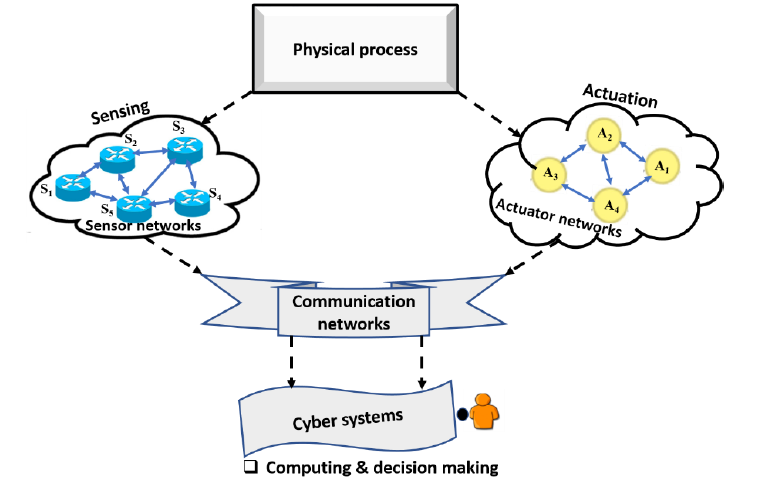

A simple view of Cyber Physical System (CPS) architecture is in figure 3.

Figure 3. Cyber Physical System (CPS) architecture

The physical process is the environment to be monitored or controlled using sensors and actuators.

The acquired information from the physical process is sent to the cyber systems (where decisions are made) through a communication network. [7]

In water 4.0, the physical process of the CPS could be the whole supply system or a section in the operation of the system such as monitoring water quality at the water treatment station, monitoring water quality and leakage flows, along the distribution networks, or monitoring energy consumption duo to pumping at the pumping stations.

In this context, different sensors and actuator mechanism such as pressure flow, water quality, accelerator sensors and control values are deployed for real-time measurement and control of physical environment. Thus, through sensors and control valve integration the provision of the real-time monitoring of water quality along the complex distribution network could be achieved.

Some essential components of CPS are sensors and actuators.

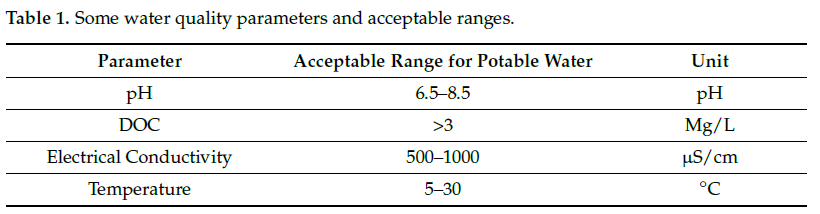

While sensors are used to gather information about the condition of the water system, actuators are used to act on the data by carrying out particular tasks according to the application. PH sensors, dissolved oxygen concentration (DOC) sensors, flow rate sensors, and turbidity sensors are the most commonly used sensors for water quality and anomaly detection. In view of this, table 1below [8] presents targeted water quality parameters with widely acceptable reargues for portable water. These values are tracked continuously to ensure that water quality is not compromised.

The DOC is a frequently monitored parameter that is used to access the pollutant level in a water system.

Table 1. Some water quality parameters and acceptable ranges

For leak detection purpose, pressure flow rate, acoustic, ultrasonic and temperature sensors are frequently used.

A combination of one or more of these sensors has been employed for leak detection purpose. The temperature sensor provides continuous measurements of the outside temperature within the pipe environment, and these data are used to create a base line. It is a general brief that a leak flow via an orifice in a pipe creates local temperature anomaly. Each temperature measurement is then compared to the baseline and a deviation from the baseline indicates the presence of a leak. The actuators used in CPS, for example, in a water quality application, perform actions such as regulating the opening and closing of the isolation valve to segregate the pipes whose water quality is compromised from the network or to halt the flow of water in such pipe.

In leakage detection application, in the event of leaks, the actuators react by overseeing the control of the pressure reducing valves to lower pressure at the nodes of the leaky pipes. The sensor reading is sent to a remote processing area for real-time water quality analysis via wireless communication technology.

The wireless communication technology used ranges from short to long range, and high to low power.

Amongst the low-power wireless communications, Sig Fox is power efficient and has the potential to cover relatively large areas in rural settings (up to 50 km). However, the rate at which these data are transmitted is relatively low.

Similar to Sig Fox in data transmission rate LoRa, WAN is another long range low power wireless communication system that can be employed due to its potential to cover up to 20 km in rural areas. [9]

4. Application of Water 4.0 #

a. Pipe line health monitoring: #

A major component of a water distribution network are pipelines for portable water delivery to end users that have been placed underground for several years. Due to ageing, or third-party intervention, damages occur to those structures which cause waste of a significant amount of water.

Pipe line health monitoring involves monitoring of pipe for corrosion, deformation and vibration as well as leaks.

A typical example is the use of smart robotics for pipe health monitoring. [10]

Furthermore, edge AI has potential to create automated closed-loop systems that continuously monitor the health of critical infrastructure.

Thus, the sustainable operation of the water supply system is guaranteed.

b. Pressure control and monitoring: #

In water distribution network, pressure sensors are mounted at nodes of the network to measure water pressures along the pipes and at each node, pressure and water demand share a good relationship.

When the demand increases, more pressure must be applied to a node to meet the increasing demand. Thus the satisfactory supply of portable water to the end users.

But when considering leaks, the reverse is the case to reduce the level of losses in the system. The issue is therefore complicated them originally assumed.

More so, consumer demand is not linear, which makes pressure control a difficult task when dealing with leak reduction.

Therefore, demand uncertainty is another issue affecting the accomplishment of good pressure control in systems.

With the advent of new technologies, if the pressure and demand at a given node can be monitored in real-time through the integration of pressure and flow sensors, an active control system for pressure control at nodes having the leaking pipes could be achieved. This is one of the features of Water 4.0. Thus, with CPS and IOT as well as the advanced control and actuator mechanism offered by this technology, optimal pressure control in real-time may be accomplished.

c. Water Quality Monitoring: #

In water quality applications, the deployment of integrated sensing devices is required to provide continuous real-time measurement of data related PH, temperature, turbidity, dissolved oxygen concentration, and chlorine residual level along the distribution network with the help of the (CPS) features of Water 4.0, which are integrated with control valves and active decision support system, an optimal decision regarding the state of water in the distribution piping network could be achieved. For instance, in a situation where contaminants are detected and quality is compromised, active decision making is required for immediate action to be taken on water contamination before it spreads to the entire system. In most cases, necessary action includes the closing of valves at the particular node where the pipe conveying the contaminated water is attached.

The valves installed at the entrance of the water distribution network could also be controlled to stop the spread of contamination.

d. Leakage Detection and Monitoring #

This is also similar to water quality monitoring applications. In this system, an integrated number of sensors such as pressure, vibration, acoustic, and flow sensors and actuators are deployed for measurement and control activities [11] in an in-pipe system is developed for pipe line leak monitoring.

Once a leak is detected and localized, monitoring of leaky pipe is required for active intervention and repair and to avoid future leak occurrence in such pipe. [12 – 14]

Thus water 4.0 could be used to provide real-time continuous monitoring to such a system.

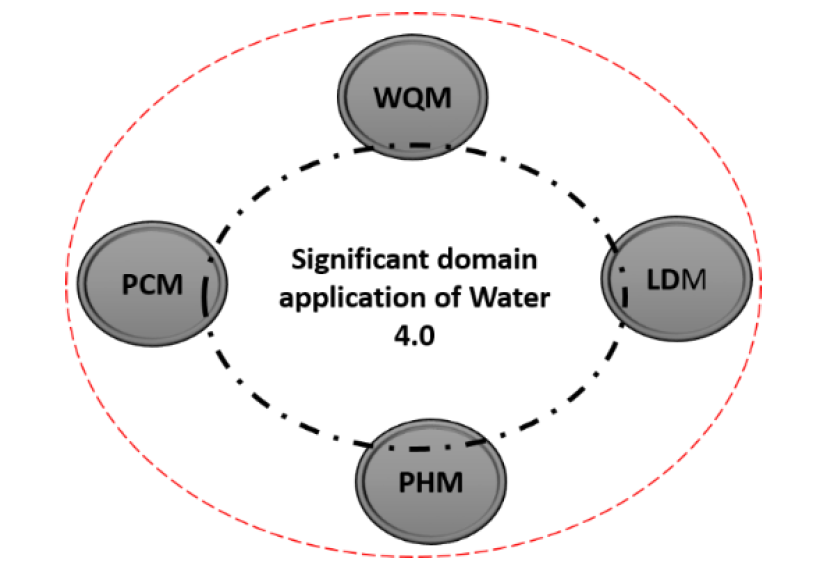

Figure 4. shows significant water supply system application domain Water 4.0

Figure 4. Application domain of water 4.0

5. Conclusion #

Finally, digital transformation of the water system for sustainable water supply is a necessity owing to the dynamic nature of water systems and consumer demand uncertainties, among others. Digital technologies have the potential to transform the operation and accordingly the maintenance of water systems by improving day-to-day water management and addressing long-term challenges and water security, with increasing use of ICT, data for the relevant water process become increasing feasible and may be analyzed using big data analysis.

Therefore, Water 4.0 is seen as a revolutionary methodology for improving operational and maintenance performance and provide real-time monitoring capabilities to complex water distribution network.

Although digital technologies are being deployed in different sub-sectors of water systems, so far, a full scale implementation has not been reported in practice. In general many challenges still need to be addressed to guarantee a smooth transition, security, data quality and uncertainties as well as energy solutions for smart sensing devices are some of the biggest challenges to be addressed and that our case study introduced.

6. References #

- Alabi, M.O.; Telukdarie, A.; Van Rensburg, N.J. Water 4.0: An integrated business model from an industry 4.0 approach. In proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 15-19 December 20149; pp. 1364-1369.

- Varghese, A.; Tandur, D. Wireless requirements and challenges in industry 4.0. In Proceedings of the IEEE International Conference on Contemporary Computing and Informatics, Mysore, India, 27-29 November 2014; pp. 634-638

- Kim, J. A review of cyber-physical system research relevant to the emerging IT trends: Industry 4.0, IoT, big data, and cloud computing. J. Ind. Integr. Manag. 2017, 2, 1750011.

- De Silva, P.; De Silva, P. Ipanera: An industry 4.0 based architecture for distributed soil-less food production systems. In Proceedings of the 1st Manufacturing and Industrial Engineering Symposium, Colombo, Sri Lanka, 22 October 2016.

- Haque, S.A.; Aziz, S.M.; Rahman, M. Review of cyber-physical system in healthcare. Int. J. Distrib. Sens. Netw. 2014, 10, 217415.

- Monostori, L. Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP 2014, 17, 9-13.

- H. Applications of cyber-physical system: A literature review. J. Ind. Integr. Manag. 2017, 2, 1750012.

- Bhardwaj, J.; Gupta, K.K.; Gupta, R. Towards a cyber-physical era: Soft computing framework based multi-sensor array for water quality monitoring. Drink. Water Eng. Sci. 2018, 11, 9-17.

- Adedeji, K.B.; Hamam, Y. Cyber-physical systems for water supply network management: Basics, challenges, and roadmap. Sustainability 2020, 12, 9555.

- Ogai, H.; Bhattacharya, B. Pipe inspection robots for structural health and condition monitoring. In Intelligent Systems, Control and Automation: Science and Engineering; Tzafestas, S.G., Ed.; Springer India: New Delhi, India, 2018.

- Chatzigeorgiou, D.M.; Youcef-Toumi, K.; Khalifa, A.E.; Ben-Mansour, R. Analysis and design of an in-pipe system for water leak detection. In Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, II, USA, 12-14 August 2012; pp. 1007-1016.

- Mandal, S.K.; Chan, F.T.; Tiwari, M.K. Leak detection of pipeline: An integrated approach of rough set theory and artificial bee colony trained SVM. Expert Syst. Appl. 2012, 39, 3071-3080.

- Layouni, M.; Hamdi, M.S.; Tahar, S. Detection and sizing of metal-loss defects in oil and gas pipelines using pattern-adapted wavelets and machine learning. Appl. Soft Comput. 2017, 52, 247-261.

- El-Zahab, S.; Abdelkader, E.M.; Zayed, T. An accelerometer-based leak detection system. Mech. Syst. Signal Process. 2018, 108, 276-291.

AERATION SYSTEM OF TALKHA

(WASTE WATER TREATMENT PLANT)

Case Study

Current situation

Large quantity of power is used during the operation due to the following reasons

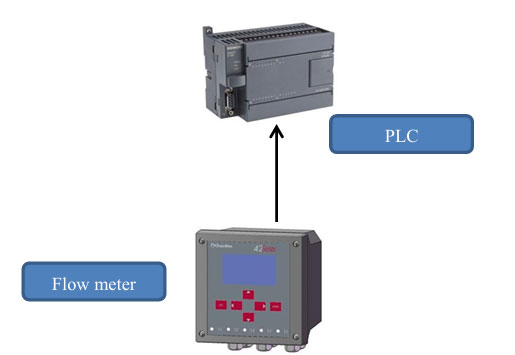

- Failure of flow meter that responsible for display and control the water quantity in the station entrance so at this time there isn’t any control on the station capacity that’s supposed to be fixed value

- Failure in 4 DO devices from 6 DO devices that are responsible for display and control the dissolved oxygen percent in the water

- Manual operation for aeration system

- Manual operation for the entrance gate

- The aeration system is working without any control

- The 12 Gearbox’s working without any sequence

Solution of Misr for Science and Technology Research

- Bill of material

| Description | Quantity | |

| 1 | Ultrasonic Flow meter | 1 |

| 2 | DO Sensor | 8 |

| 3 | Modulating Actuator | 2 |

| 4 | Siemens Plc. [ Digital , Analog ] module | 1 |

| 5 | IP Control Panel | 1 |

| 6 | Schneider Relay | 12 |

| 7 | Schneider Selector | 4 |

| 8 | Indication lamp | 14 |

| 9 | Gear Motor | 12 (Existing) |

| 10 | Control wires | ……. |

| 11 | Set of Control Terminal | ……. |

| 12 | Horn | 1 |

| 13 | Actuator | 3 (Existing) |

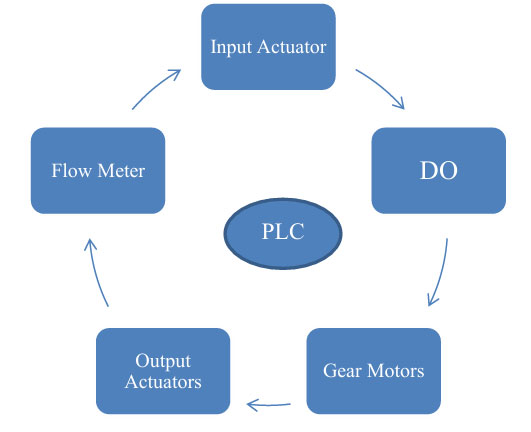

2. Misr for Science and Technology Research solution

3. Critical Parameters:

- Quantity of the entrance water to be the actual value that the station was designed for it

- Sequence between the 3 Gearbox’s in each tunnel

- The operation time of the gearbox’s

- The dissolved oxygen to be suitable for aeration system

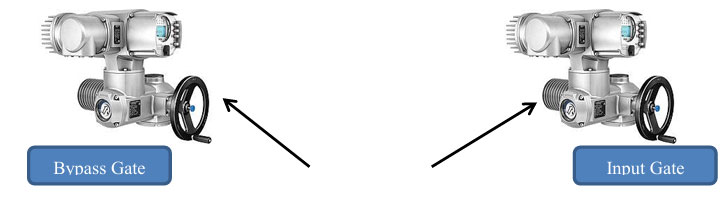

- The aeration system output gate

- The gate of the bypass system

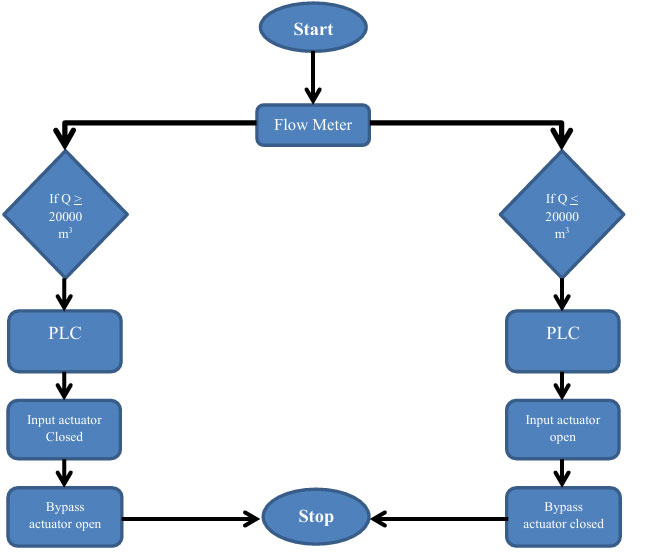

A. Quantity of the entrance water to be the actual value that the station was designed for it

This station is designed for 20,000 m3/D so the first step in our solution is must be keeping the capacity of the station at the designed value, and we will do that by making the following

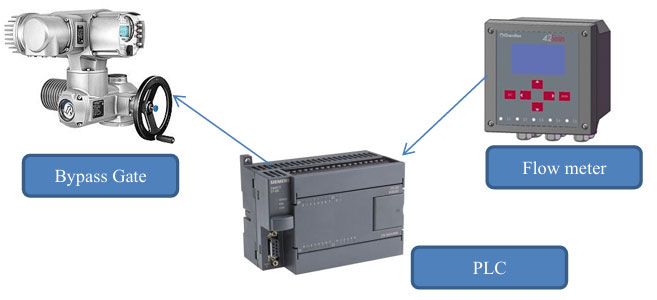

- Create smart solution by using PLC to making communication between the actuator of the input gate and the actuator of bypass system and also the flow meter that responsible for display and control on the input quantity .

A.1. Theory of operation

A.2. Saving:

By Keeping the capacity of the station at the designed value we will Saving More than 20% of complete station operation such as [Screw pump, Gearbox’s,…..]

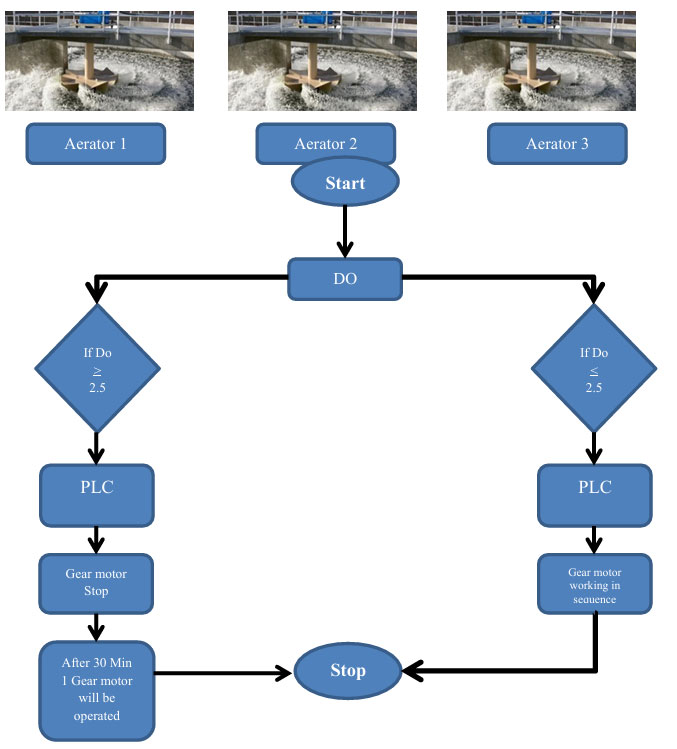

B. Sequence between the 3 Gearbox’s in each tunnel

We designed our solution to be useful not only for saving power but also to make smart sequence between the gear motors that are used for aeration system and that will be useful for the following

- Keeping the life time of each gear motor because our system grantee that the operation time of the 3 gear motors are equal

- Grantee also the saving of the power because our system making smart sequence between the 3 gear motors and because of that it didn’t allow staring more than one gear motor at the same time

B.1. Saving:

- Gearbox’s life time

- Motors starting

C. The operation time of the gearbox’s

We designed our system to make sure that the gear motors are operating to make the require oxygen percent once the required percent is achieved the gear motors must be turned off but with keeping the percent at the required value and also keeping the water moving in the tunnel and that will useful for the following

- Saving the power

- grantee that the operation time of the 3 gear motors are equal

- avoid water stagnation in the tunnel

C.1. Saving:

- % of Aerators operation time (45 KW)

- Gearbox’s life time

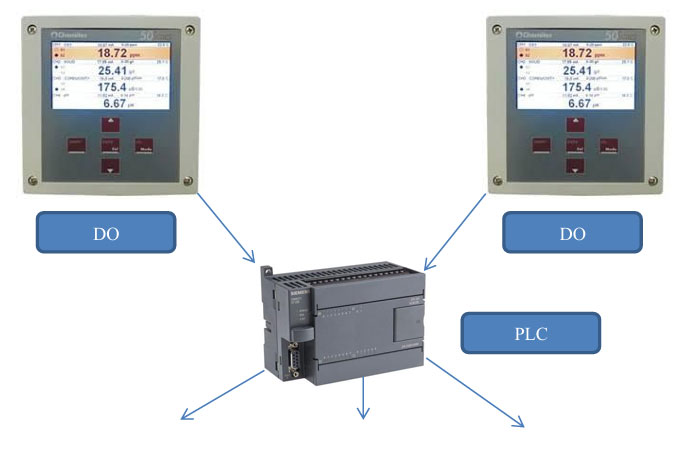

D. The dissolved oxygen to be suitable for aeration system

The required oxygen percent to achieve the aeration system is 2:2.5 Kg.m3 in our solution we must keeping the oxygen percent at the required value, and we will do that by making the following

- Create smart solution by using PLC to making communication between the Do sensors and the 3 Gear motors.

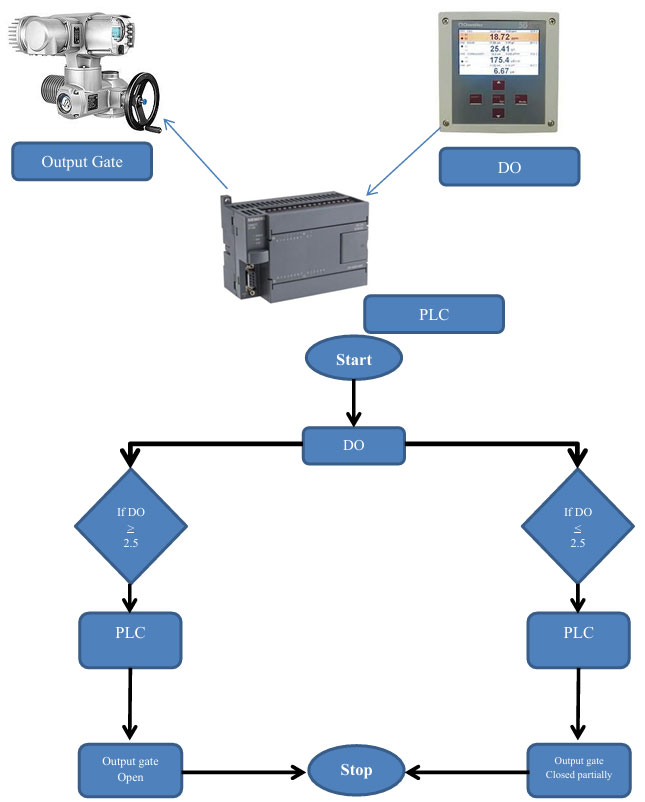

E. The aeration system output gate

We must making control on the output gate of the aeration system to make sure that the Water will not be released without completing the ventilation process

E.1. Theory of operation

F. The gate of the bypass system

By Making the control of the bypass gate we grantee that the following will be achieved

- The capacity of the station will be the value that the station was designed for

- We will not need to operate the system more than the time that required to complete the treatment of the quantity that the station was designed for

- Power saving

- Saving the life time of the system devices

F.1. Theory of operation

The advantages of the solution introduced by Misr Foundation for Science and Technology Research

- Saving More than 25% of the absorbed power of the aeration system

- Saving More than 20% of the absorbed power of the station component

- Saving the life time of the system component

- Make sure that the quantity will be the quantity that the station was designed for not more

- Safety on the system component

- Alert in case of an system error

- Automatic operation for the aeration system

- Provided also manual operation in case of system failure

- Ensure that the ventilation process will be done properly

- Safety on the Motors incase operation error