Amr Mohamed Mhamoud[1], Ahmed AlGhamdi[1],Sultan Ahmed[1], Aleksejs Zol[2], Aleksejs Zolotarjovs[2], Ģirts Ozoliņš[2]

[1] Water Technologies Innovation Institute and Research Advancement (WTIIRA), Saudi Water Authority SWA, Saudi Arabia

[2] Institute of Solid State Physics, University of Latvia

Abstract #

Membrane biofouling is one of the critical challenges faced by desalination plants, particularly those utilizing reverse osmosis (RO). The development of advanced monitoring technologies is essential to reduce maintenance costs, improve efficiency, and increase the lifespan of the membranes. Spectromarine, an innovative optical water quality measurement sensor, provides real-time data on organic content and biomass levels in water to desalination operators, offering early warnings to prevent membrane fouling. This paper discusses the design, application, and expected outcomes of the Spectromarine sensor in optimizing desalination processes, with a focus on reducing operational costs, energy consumption, and chemical use, while enhancing plant performance.

1. Introduction #

Desalination plants, particularly those using reverse osmosis (RO) technology, face significant operational challenges related to biofouling of membranes, which can lead to reduced productivity, higher operational costs, and increased energy consumption [1,2]. The formation of biofilms on membrane surfaces impedes water flow, requiring higher pressure and more frequent chemical cleaning, which in turn reduces the membrane’s lifespan [3,4].

Current methods to monitor biofouling include heterotrophic plate count (HPC) and flow cytometry, both of which present limitations in terms of response time and accuracy. HPC, for instance, requires several days to weeks for bacterial growth and analysis, which delays intervention measures [5]. Flow cytometry, while faster, often underestimates biofouling due to bacterial clumping and still requires manual labor for sample collection and analysis [6].

Spectromarine, an innovative optical sensor, aims to address these limitations by providing real-time monitoring of water quality in desalination plants [7]. By combining fluorescence and absorption spectroscopy with advanced data analysis techniques, Spectromarine can deliver instant analytics, allowing operators to take immediate action to mitigate biofouling risks. This technology not only optimizes water pretreatment but also reduces membrane cleaning frequency, chemical usage, and overall operational costs [8,9].

2. Methodology #

2.1 Sensor Design and Functionality #

The Spectromarine sensor utilizes a combination of fluorescence and absorption spectrometry to measure dissolved organic matter (DOM), total organic carbon (TOC), humic substances, algae, and particulate matter in real-time [10]. Installed at various points in the desalination process, the sensor continuously monitors water quality, providing data with a frequency of up to 10 seconds [11].

The sensor consists of two main components:

– Hardware (Spectromarine HW): A compact device capable of performing full-spectrum optical measurements at different excitation wavelengths.

Fig. 1. Spectromarine hardware

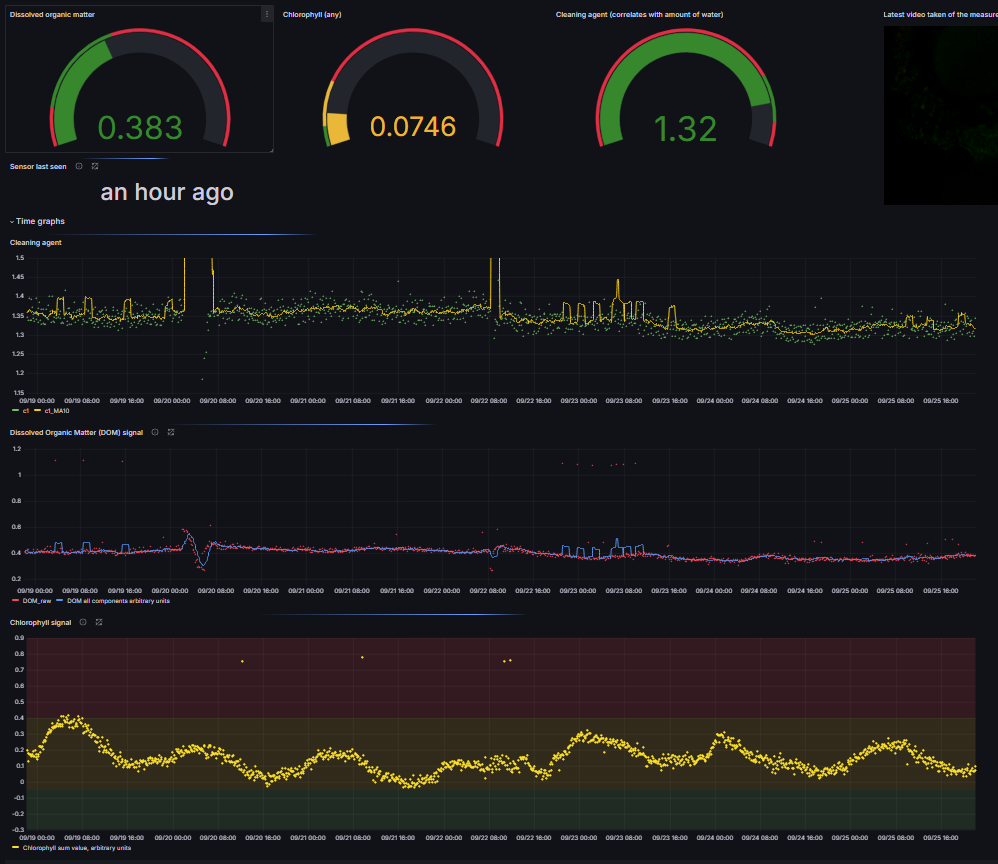

– Software Interface: A dashboard that provides real-time data visualization, tailored to the operator’s needs. The software integrates Internet of Things (IoT) technologies, allowing remote monitoring and control through mobile or desktop devices [12].

Fig. 2. Spectromarine real-time data platform

2.2 Operational Integration in Desalination Plants #

The sensor is integrated at critical points in the desalination process, primarily in the pretreatment stages before reverse osmosis [13]. Its primary functions include:

1. Real-time Biofouling Detection: Continuous measurement of organic material and algae that contribute to biofouling [14].

2. Early Warning System: Alarms operators when water quality deteriorates, allowing timely adjustments in pretreatment or membrane cleaning processes [15].

3. Data Analysis and Recommendations: Spectromarine’s software processes the collected data and provides actionable insights, such as adjusting chemical dosing or changing water source intake to prevent fouling [16].

2.3 Field Testing and Validation #

The Spectromarine sensor has undergone preliminary field testing in cooperation with the Water Technology Institute for Research and Applications (WTIIRA) and the Institute of Solid State Physics, University of Latvia (ISSP UL). During the two-month test period, the sensor required only minimal maintenance (light cleaning of the sensor window), demonstrating its robustness and low maintenance needs [17].

Further extended tests are planned to validate the sensor’s performance under various operational conditions, particularly its ability to predict membrane fouling and optimize chemical usage [18]. For this primary aim, the low detection limit and selectivity of the device can be tested extensively, with advanced data analysis implemented for predictive decision making and water parameter change projection (e.g. chlorophyll cyclice development)

3. Expected Results #

The Spectromarine project aims to deliver the following key results:

3.1 Reduction in Operational Costs #

By providing real-time water quality monitoring and early warnings, Spectromarine is expected to significantly reduce the operational costs of desalination plants. Reduced membrane biofouling will decrease the frequency of membrane cleaning and replacement, which typically accounts for 10-20% of operating costs [19]. Additionally, timely detection of water quality issues will minimize downtime and ensure continuous production [20].

3.2 Optimization of Energy Consumption #

Membrane fouling increases the pressure required for filtration, leading to higher energy consumption [21]. By preventing fouling, Spectromarine will optimize energy use, thereby reducing greenhouse gas emissions and lowering the overall energy costs associated with desalination [22].

3.3 Minimization of Chemical Usage #

Spectromarine will enable more efficient chemical dosing by providing accurate, real-time data on water quality. This will not only reduce the amount of cleaning chemicals used during membrane maintenance but will also optimize the pre-treatment process, resulting in less environmental impact and lower operational costs [23].

3.4 Enhancement of Membrane Lifetime #

The primary benefit of the Spectromarine sensor is the extended lifetime of desalination membranes. By minimizing biofouling, the sensor will reduce the physical and chemical stresses on membranes, leading to longer operational life and lower replacement costs [24].

4. Discussion #

Spectromarine represents a significant advancement in desalination technology by combining real-time water quality monitoring with IoT integration. The project’s success would establish a new standard in desalination plant operation, allowing operators to maintain high levels of production efficiency while reducing both costs and environmental impact [25].

The use of real-time spectroscopic data provides a more accurate and immediate assessment of water quality than traditional methods, allowing operators to make informed decisions about pretreatment and membrane cleaning [26]. Additionally, the system’s low maintenance requirements and easy installation make it a cost-effective solution for desalination plants globally [27].

Future research will focus on the expanded application of the Spectromarine sensor, particularly in other industries such as aquaculture, environmental monitoring, and urban pollution control [28].

5. Conclusion #

Spectromarine is poised to revolutionize the desalination industry by offering a practical solution to biofouling, one of the most persistent challenges in reverse osmosis systems. The sensor’s real-time water quality measurements and advanced data analytics will enhance plant efficiency, lower operational costs, and reduce the environmental impact of desalination processes. With its proven low-maintenance design and market readiness, Spectromarine has the potential to become a cornerstone technology for water desalination in the Gulf region and beyond [29].

References #

1. M. Elimelech, W.A. Phillip, The future of seawater desalination: Energy, technology, and the environment, Science, 333 (2011) 712-717.

2. C.Y. Tang, Q.S. Fu, A.G. Fane, R. Wang, C. Hu, Y. Zhao, Forward osmosis desalination using polyelectrolyte hydrogels as draw agents: Influence of draw agent, feed solution and membrane on process performance, Desalination, 368 (2015) 34-40.

3. L. Zhang, J.S. Zhang, H. Ma, Biofouling in seawater desalination membranes, Desalination, 346 (2014) 158-167.

4. R. Valladares Linares, Z. Li, M. Abu-Ghdaib, T. Yangali-Quintanilla, D. Amy, T. Leiknes, Water harvesting from municipal wastewater via forward osmosis using nanocomposite membranes, Desalination, 277 (2011) 144-149.

5. H. Alzahrani, A.W. Mohammad, Challenges and trends in membrane technology implementation for desalination, Desalination, 452 (2019) 158-174.

6. S. Kwon, W.S. Shin, W. Kim, S. Kim, P. Na, Biofilm monitoring using an optical sensor in reverse osmosis desalination plants, Desalination, 451 (2019) 48-57.

7. M. Elimelech, J. Laîné, P. Hong, Online fouling monitoring of seawater reverse osmosis desalination plants, Desalination, 239 (2009) 10-25.

8. N. Hilal, A. Al-Zoubi, N.A. Darwish, A.W. Mohammad, Characterization of nanofiltration membranes using atomic force microscopy, Desalination, 214 (2007) 187-194.

9. C. Boo, Y. Lee, D.J. Rho, T. Nguyen, M. Elimelech, Influence of cleaning agents on forward osmosis membrane performance, Desalination, 349 (2014) 67-73.

10. P. Xu, J.E. Drewes, C. Bellona, G. Amy, J. Heberer, T. Kimura, M. Watanabe, Rejection of emerging organic micropollutants in membrane systems, Desalination, 239 (2009) 244-260.

11. D.M. Warsinger, S.M. Chakraborty, E.W. Tow, J.H. Lienhard V,